![]()

![]()

![]()

Use LEFT and RIGHT arrow keys to navigate between flashcards;

Use UP and DOWN arrow keys to flip the card;

H to show hint;

A reads text to speech;

154 Cards in this Set

- Front

- Back

- 3rd side (hint)

|

CARPENTRY |

is a skilled trade and a craft in which the primary work performed is the cutting, shaping and installation of building materials during the construction of buildings, ships, timber bridges, concrete formwork, etc. The art and trade of cutting, working, and joining timber.

|

|

|

|

JOINERY |

Is a part of woodworking that involves joining together pieces of timber or lumber, to produce more complex items. |

|

|

|

TRADITIONAL WOODWORKING JOINTS |

● BUTT JOINT ● LAP JOINT ● BRIDLE JOINT ● DOWEL JOINT ● MITRE JOINT ● BOX JOINT ● DOVETAIL JOINT ● DADO JOINT ● GROOVE JOINT ● TONGUE AND GROOVE ● MORTISE AND TENON ● BIRDSMOUTH JOINT ● SPLICE JOINT |

|

|

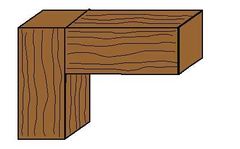

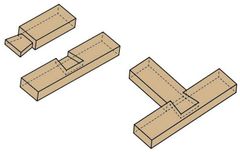

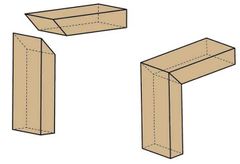

BUTT JOINT |

The end of a piece of wood is butted against another piece of wood. This is the simplest and weakest joint. Of those, there is the ● T-Butt ● End-to-End Butt ● T-Lap ● Miter Butt ● Edge-To-Edge Butt.

|

|

|

LAP JOINT |

The end of a piece of wood is laid over and connected to another piece of wood. This is the next simplest and weakest joint. |

|

|

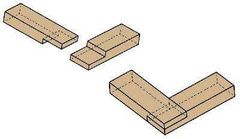

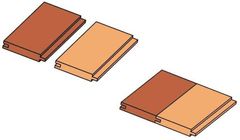

HALF LAP |

Also known simply as a pull lap, it is the basic form of the lap joint and is used when joining members end to end either parallel or at right angles. When the joint forms a corner, as in a rectangular frame, the joint is often called a corner lap. |

Use for: ● Internal cabinet frames ● Visible frames when the frame members are to be shaped. |

|

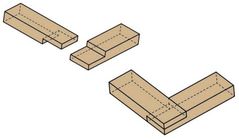

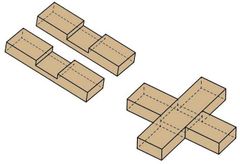

CROSS LAP |

The main difference between this and the basic half lap is that the joint occurs in the middle of one or both members, rather than at the end. The two members are at right angles to each other and one member may terminate at the joint, or it may carry on beyond it. When one of the members terminates at the shin, it is often referred to as a tee lap or middle lap. |

Use for: ● Internal cabinet frames ● Simple framing and bracing |

|

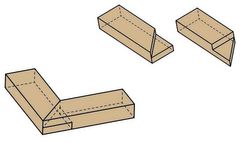

DOVETAIL LAP |

This is a lap in which the housing has been cut at an angle which resists withdrawal of the stem from the cross-piece. |

Use for: ●Framing applications where tension forces could pull the joint apart |

|

MITRED HALF LAP |

is the weakest version of the joint because of the reduced gluing surface. |

Use for:● Visible framing applications where a mitred corner is desired |

|

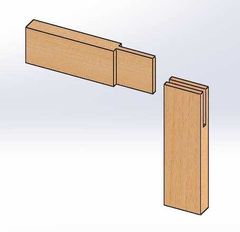

BRIDLE JOINT |

Also known as open tenon, open mortise and tenon, or tongue and fork joints, this joint is where the through mortise is open on one side and forms a fork shape. The mate has a through tenon or necked joint. Bridle joints are commonly used to join rafter tops, also used in scarf joints and sometimes sill corner joints in timber framing.

|

|

|

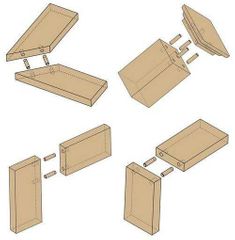

DOWEL JOINT |

The end of a piece of wood is butted against another piece of wood. This is reinforced with dowel pins. This joint is quick to make with production line machinery and so is a very common joint in factory-made furniture. |

|

|

MITRE JOINT |

Similar to a butt joint, but both pieces have been bevelled (usually at a 45 degree angle). |

|

|

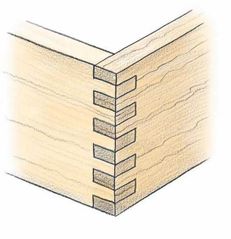

BOX JOINT |

A corner joint with interlocking square fingers. Receives pressure from two directions. |

|

|

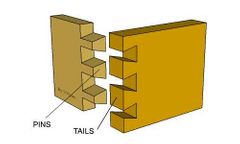

DOVETAIL JOINT |

A form of box joint where the fingers are locked together by diagonal cuts. More secure than a box joint. |

|

|

DADO JOINT |

Also called a housing joint or trench joint, a slot is cut across the grain in one piece for another piece to set into; shelves on a bookshelf having slots cut into the sides of the shelf, for example. |

|

|

GROOVE JOINT |

Like the dado joint, except that the slot is cut with the grain. |

|

|

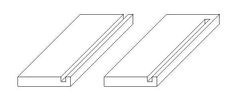

TONGUE AND GROOVE |

Each piece has a groove cut all along one edge, and a thin, deep ridge (the tongue) on the opposite edge. If the tongue is unattached, it is considered a spline joint.

|

|

|

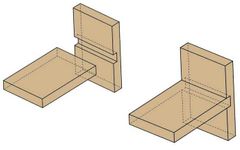

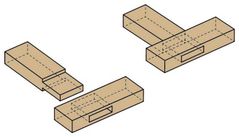

MORTISE AND TENON |

A stub (the tenon) will fit tightly into a hole cut for it (the mortise). This is a hallmark of Mission Style furniture, and also the traditional method of jointing frame and panel members in doors, windows, and cabinets. This joint is a good strong joint to use. |

|

|

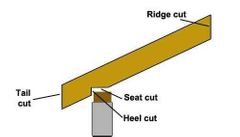

BIRDSMOUTH JOINT |

Also called a bird's beak cut, this joint used in roof construction. A V-shaped cut in the rafter connects the rafter to the wall-plate. |

|

|

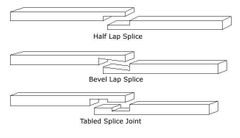

SPLICE JOINT |

A joint used to attach two members end to end. |

|

|

|

FASTENER |

Is a hardware device that mechanically joins or affixes two or more objects together. In general, fasteners are used to create non-permanent joints; that is, joints that can be removed or dismantled without damaging the joining components. |

|

|

NAILS |

are a basic type of fastener and have been used in construction in some form for at least 3,000 years. They are most commonly used for joining pieces of timber or for fastening materials to timber and are suitable when a screw is unnecessary. |

|

|

|

TYPES OF NAILS |

● COMMON NAILS ● FINISHING NAILS ● BOX NAILS ● ROOFING NAILS ● MASONRY NAILS ● DOUBLE - HEADED NAILS ● DRYWALL NAILS ● ANNULAR RING SHANK NAILS |

|

|

COMMON NAILS |

Also known as round head, these are the most widely-used type of nail for joining timber and other elements, particularly where a rougher finish is acceptable. It is good practice to use nails that are at least three times longer than the depth of the thinner material that is being nailed. A variation is the oval head nail which is oval in cross-section and minimises the risk of splitting the timber.

|

|

|

FINISHING NAILS |

These are similar to common nails but have much smaller heads which sit flush with the timber surface and provide a neater finish. A nail set can be used to recess the head to conceal it completely. This capability means that they are often used in furniture and decorative or exposed timber. The smaller head sizes also mean there is a reduced risk of the timber splitting. |

|

|

BOX NAILS |

Are commonly used for light construction as they are slightly thinner than common nails and have less strength. |

|

|

ROOFING NAILS |

These have larger heads and are often used for nailing shingles, attaching asphalt and other roofing purposes. The thin material is held in place and prevented from tearing loose by the large head. Smaller varieties can be used to attach roofing felt. |

|

|

MASONRY NAILS |

These are harder and thicker nails with small heads, typically made of hardened zinc which is stronger, enabling them to be driven into masonry surfaces effectively. They are often used to attach timber to stone or brick. |

|

|

DOUBLE-HEADED NAILS |

These nails are often used to secure scaffolding and other temporary structures in place. They have two heads, one above the other. They are driven in as far as the first head, while the top head remains above the surface, making it easy to remove. |

|

|

DRYWALL NAILS |

Are used to hang drywall and are designed not to cut the paper face. |

|

|

ANNULAR RING SHANK NAILS |

These are similar to common nails but comprise rings along the length of the shank. This provides better grip in the timber and a more secure attachment. |

|

|

|

SPECIAL TYPES OF NAILS |

● CASING NAIL ● BRADS NAIL ● GLAZING SPRIG NAIL ● CAP NAIL ● UPHOLSTERY NAIL ● CARPET NAIL ● CORRUGATED NAIL ● STAPLE NAIL |

|

|

CASING NAIL |

For use on small mouldings or thin plywood. |

|

|

BRADS NAIL |

Very narrow nails that provide a neat finish. Typically used in nail guns for fast fixing. |

|

|

GLAZING SPRIG NAIL |

A wedge-shaped nail that can be used with putty to secure glazing. |

|

|

CAP NAIL |

Includes a plastic cap and is commonly used for nailing building fabrics. |

|

|

UPHOLSTERY NAIL |

Small, dome-headed nails that are used for attaching upholstery to furnishings. |

|

|

CARPET NAIL |

Also known as carpet tacks, they are used to hold down carpet in awkward areas such as corners and stairs. |

|

|

CORRUGATED NAIL |

Has a corrugated cross-section, often used as an 'invisible' connector. |

|

|

STAPLE NAIL |

Has an arched shape for holding wire in position on structures such as fenceposts. |

|

|

BOLTS |

is a type of fastener, usually made from metal, that commonly comprises a head at one end, a chamfer at the other, and a shaft characterised by an external helical ridge known as a ‘thread’. They are typically used to hold materials or objects together, or to position objects. |

|

|

|

TYPES OF BOLTS |

● ANCHOR BOLT ● CARRIAGE BOLT ● ELEVATOR BOLT ● FLANGE BOLT ● HANGER BOLT ● HEXAGON BOLT OR TAP BOLT ● LAG BOLT ● MACHINE BOLT ● PLOW BOLT ● SEX BOLT ● SQUARE BOLT ● STUD BOLT ● TIMBER BOLT ● T - HEAD BOLT ● TOGGLE BOLT ● U - BOLT |

|

|

ANCHOR BOLT |

Usually embedded in concrete or masonry for structural applications. |

|

|

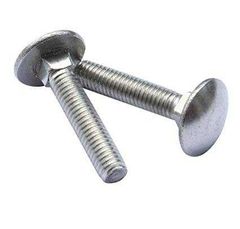

CARRIAGE BOLT |

Used to fasten metal to timber, with a squared undercut to the head which holds the bolt in place once it has been tightened. |

|

|

ELEVATOR BOLT |

Commonly used in conveyor systems, it has a flat, plain or countersunk head which holds the bolt in place when tightened. |

|

|

FLANGE BOLT |

Also known as frame bolts, this type of bolt distributes the bearing load using a washer on the undercut of the head. |

|

|

HANGER BOLT |

This type of bolt comprises two threaded ends instead of having a head, one of which contains a wood screw. |

|

|

HEXAGON BOLT OR TAP BOLT |

comprises a head that has six sides, with threading that begins part-way down the shank, whereas a tap bolt’s shank is threaded the whole length. |

|

|

LAG BOLT |

Also known as lag screws, this is a heavy-duty fastener that creates its own mating thread in timber and other soft materials when tightened. |

|

|

MACHINE BOLT |

This type of bolt has a short shank and is intended for assembling metal components through predrilled holes. |

|

|

PLOW BOLT |

This type of bolt is commonly used in construction tools and other devices due to its durability, and is characterised by its flat countersunk head and square shank neck. |

|

|

SEX BOLT |

Rather than requiring a nut, the shank of these bolts are covered with a ‘mating’ female component. These are useful for fastening components that cannot be exposed to abrasive threads. |

|

|

SQUARE HEAD BOLT |

This is similar to a machine bolt in that it has a short shank, in addition to a four-sided bolthead. |

|

|

STUD BOLT |

This type of bolt has hexagon nuts on both ends. Components are fastened between the two bolts. |

|

|

TIMBER BOLT |

Bolts that are meant for use with large timber components. |

|

|

T-HEAD BOLT |

Has a T-shaped head which can be gripped by a wench and can fit into a slot with ease. |

|

|

TOGGLE BOLT |

This type of bolt has an expanding wing-like nut which helps it to mount objects to walls. |

|

|

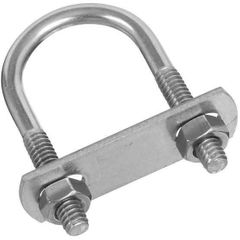

U - BOLT |

Similar to staples, they are bent in the shape of a ‘U’ and are partially threaded on both ends. |

|

|

|

TYPES OF BOLT HEADS |

● SQUARE SHOULDER ● INDENTED HEXAGON ● INDENTED HEXAGON WASHER ● HEXAGON ( TRIMMED ) ● HEXAGON FLANGE |

|

|

SQUARE SHOULDER |

A truss head, shaped so as to allow fastening with the least amount of surface obstruction, on a square shank which resists rotation. |

|

|

INDENTED HEXAGON |

For use with a wrench, this head has a circular depression in its top surface. |

|

|

INDENTED HEXAGON WASHER |

Same as an indented hexagon, but with the addition of a washer section at the base to protect the assembly finish from the wrench. |

|

|

HEXAGON ( TRIMMED ) |

Standard type of head, with clean corners that are trimmed to close tolerances. |

|

|

HEXAGON FLANGE |

Similar to the indented hexagon washer, but the washer is conical or slightly rounded. |

|

|

NUT |

Is a fastener that consists of a block with a threaded hole in the centre. The hole contains ‘female’ threads that typically correspond to the ‘male’ threads of a bolt or screw. Nuts are used with their ‘mating’ bolt or screw to fasten materials together. |

|

|

|

TYPES OF NUT |

● BASIC HEX NUT ● WING NUT ● CAP NUT ● ACORN NUT ● BARREL NUT ● CAGE NUT ● COUPLING NUT ● FLANGE NUT ● INSERT NUT ● SPLIT NUT ● SQUARE NUT ● SWAGE NUT ● T - NUT ● WELD NUT |

|

|

BASIC HEX NUT |

A six-sided nut, and the most common type. There are several variations such as the nylon insert lock which helps secure the nut in place. |

|

|

WING NUT |

The head of its nut has two ‘wings’ on each side, enabling it to be tightened and loosened by hand. Mainly used for temporary fastening. |

|

|

CAP NUT |

This type of nut is closed at one end with a smooth-domed top. |

|

|

ACORN NUT |

Similar to a cap nut but the rounded end has a higher crown. |

|

|

BARREL NUT |

Also known as a dowel nut, this has a round ‘slug’ with threads perpendicular to its length. |

|

|

CAGE NUT |

A spring steel cage wraps around the nut with wings that can be used to compress and release the nut. |

|

|

COUPLING NUT |

A threaded fastener for joining two male threads together, such as in pipework, or to make long rod assemblies from shorter lengths. |

|

|

FLANGE NUT |

A wide flange at one end acts as an integrated washer, distributing the pressure of the nut over the part being secured. |

|

|

INSERT NUT |

Inserted into a pre-drilled hole to provide a threaded socket. |

|

|

SPLIT NUT |

Split into two pieces to allow the female thread to open and close over the male thread of a bolt or screw. |

|

|

SQUARE NUT |

A four-sided nut which provides greater resistance to loosening. |

|

|

SWAGE NUT |

Also known as a self-clinching nut, this is used to permanently anchor itself onto sheet metal. |

|

|

T - NUT |

A long, thin body with a T-shaped flange at one end which digs in, leaving a flush surface. |

|

|

WELD NUT |

A specialised nut that can be welded to another component. |

|

|

SCREW |

A type of fastener, usually made from metal, that commonly comprises a head at one end, and a point at the other, and a shaft shaped so that it can be turned into another material. The shape of the shaft is characterised by a helical ridge which is known as a ‘male thread’ (where the thread is external) or ‘female thread’ (where the thread is internal). They are typically used to hold materials or objects together, or to position objects. |

|

|

|

TYPES OF SCREWS |

● WOOD SCREW ● CONCRETE SCREW ● MASONRY SCREW ● DOUBLE ENDED SCREW ● DRIVE SCREW ● DRYWALL SCREW ● EYE BOLT ● DECKING SCREW ● LAG SCREW ● CHIPBOARD SCREW ● MIRROR SCREW ● TWINFAST SCREW ● SECURITY HEAD SCREW |

|

|

WOOD SCREW |

Typically designed with a partially-unthreaded shank and used to attach pieces of timber together. |

|

|

CONCRETE SCREW |

Stainless or carbon steel and used for fastening materials to concrete. |

|

|

MASONRY SCREW |

Often have a blue coating and are inserted to a pilot hole in masonry. |

|

|

DOUBLE ENDED SCREW |

Have two pointed ends and no head. Often used for making hidden joints between two pieces of timber. |

DOWEL SCREW |

|

DRIVE SCREW |

Smooth, round or mushroom-headed with a reduced diameter shank. |

|

|

DRYWALL SCREW |

Often coated with black phosphate and designed with a bugle head. Used to attach drywall to timber or metal studs. |

|

|

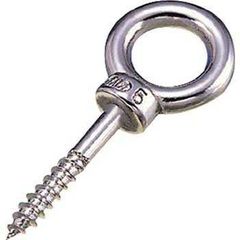

EYE BOLT |

A looped head designed to be used as an attachment point. Also used for attaching wires across building surfaces. |

|

|

DECKING SCREW |

Longer screws which are used for fastening down deck boards. |

|

|

LAG SCREW |

A heavy-duty fastener. |

|

|

CHIPBOARD SCREW |

Often wax-coated and used for fastening down chipboard flooring. |

|

|

MIRROR SCREW |

Designed with a decorative dome or other cover to conceal the head. |

|

|

TWINFAST SCREW |

Designed with two threads which enable it to driven twice as fast. |

|

|

SECURITY HEAD SCREW |

Designed with a head that is impossible to reverse, making it suitable for security applications. |

|

|

|

TYPES OF SCREW HEADS |

● PAN HEAD ● BUTTON / DOME HEAD ● ROUND HEAD ● MUSHROOM HEAD ● COUNTERSUNK / FLAT HEAD ● OVAL / RAISED HEAD ● BUGLE HEAD ● CHEESE HEAD ● FILLISTER HEAD ● FLANGED HEAD |

|

|

PAN HEAD |

Rounded, high outer edge with a large surface area. |

|

|

BUTTON / DOME HEAD |

Cylindrical head with a rounded, dome-like top. |

|

|

ROUND HEAD |

Dome-shaped and used mainly for decorative purposes. |

|

|

MUSHROOM HEAD |

The dome has a lower profile that is designed to prevent tampering. |

|

|

COUNTERSUNK / FLAT HEAD |

Conical head with a flat outer face and a tapered inner face. |

|

|

OVAL / RAISED HEAD |

Countersunk bottom and rounded top, often used decoratively. |

|

|

BUGLE HEAD |

A smooth transition from the shank to the angle of the head. |

|

|

CHEESE HEAD |

A disc with a cylindrical outer edge. |

|

|

FILLISTER HEAD |

Cylindrical with a slightly convex top surface. |

|

|

FLANGED HEAD |

Can be any style but has the addition, at the base of the head, of an integrated flange which means it does not require a washer. |

|

|

|

CARPENTER'S TOOLS |

F |

|

|

STANDARD SAW |

A good-quality hand saw is worth every penny you spend and should not be overlooked. They are simple and easy to use - the fundamental carpenter's tool. |

|

|

COPING SAW |

is a hand tool that allows you to cut intricate shapes and irregular lines. Frequently used for cutting mouldings and shaped joints. |

|

|

HACK SAW |

is a staple of the carpenter's toolbox. It is robust and durable and will cut through nearly anything. It is particularly useful for carpenters who need to remove existing bolts and frames. |

|

|

TENON SAW |

rigid blade and fine teeth make it an excellent tool for cutting with great precision and for neater cuts. A must for cutting tenon joints. |

|

|

RIP SAW |

Designed specifically for cutting across the grain, a rip saw's coarse teeth won't give you a neat finish but it will cut very quickly making it very useful for fast timber frame work. This saw should be part of any carpenter's arsenal. |

|

|

KEYHOLE SAW |

long narrow blade is used to cut small, often awkward shapes and holes in a variety of building materials. |

|

|

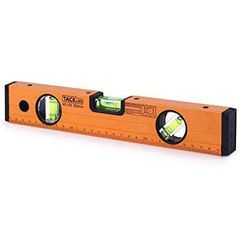

SPIRIT LEVELS |

These tools give you accurate measurements of the flatness of a surface. |

|

|

SCREWDRIVERS |

is a tool, manual or powered, for screwing and unscrewing screws. |

|

|

TAPE MEASURE |

is a handy gadget that typically extends up to 5 metres, though there are longer models. Accuracy is key with any kind of measurement, so making sure the "hook" on the end is securely attached is important. |

|

|

CLAW HAMMER |

is probably the most basic tool in any household or workshop. It has a heavy blunt end for striking and a rounded claw end for prying and removing nails. |

|

|

WOOD MALLET |

is typically used by carpenters to drive wooden workpieces together or to drive dowels. |

|

|

QUICK CLAMPS |

You'll need them for making 45 and 90 degree joints, not to mention a wide variety of carpentry tasks. These are simple to use and provide that vital extra pair of hands when you need them most. |

|

|

TABLE SAW |

is the real workhorse of any carpenter's workshop, so invest in a good one. You'll use it to rip, groove, join, shape, square, mitre, and slice - a quality one that suits your needs is essential. |

|

|

PRY BAR |

is a must-have tool for any carpenter. It can pry open pretty much anything if the right leverage is applied, and if nothing else, it will save you damaging your screwdrivers. |

|

|

PENCIL |

has various uses and applications, from marking measurments on your workpiece to filling in the crossword at lunchtime. Will fit snugly behind an ear for easy access. |

|

|

LARGE CLAMPS |

are extremely useful tools and are used in many carpentry tasks. They can be used to hold, secure and grip anything that will fit between their jaws and will allow you to keep both hands free while working. |

|

|

DOOR LIFT |

This simple looking tool makes fitting doors a breeze. The tapered front end of it slips neatly under boards and doors and holds them securely in place. |

|

|

BRADAWL |

is a simple tool incorporating a sharp, pointed metal shaft that is used to mark an indentation in wood for a nail or screw to go in. |

|

|

NAIL PULLER |

Designed to remove difficult nails from timber. |

|

|

RETRACTABLE TRIMMING KNIFE |

A carpenter will use it when scribing wood, cleaning out mortise joints, or just sharpening their pencil. |

|

|

MARKING GAUGE |

is used to mark parallel lines on a workpiece prior to cutting. It is used in many carpentry tasks. |

|

|

SLIDING BEVEL |

If you need to set an angle and mark off a lot of timbers. |

|

|

METAL RULE |

is used to measure distances between two points. The straight edge can be used to rule lines. Thoroughly useful to carpenters and DIYers of all levels of ability. |

|

|

LONG TAPE |

is essentially a tape measure with extra reach. |

|

|

NAIL PUNCH |

They are used to drive nails flush with or just below the surface of a workpiece so that the resulting cavity can be filled with wood-filler and smoothed off, leaving the nail heads undetectable and the wood ready for painting or staining. |

|

|

BENCH VICE |

Having one of these at your disposal is like having an extra pair of strong hands. Great for holding workpieces securely so that you are free to work with both hands. |

|

|

BLOCK PLANE |

can flatten a piece of wood or add a curve to it. It can square your work, chamfer and soften those sharp edges. |

|

|

BALL PEIN HAMMER |

is traditionally a metal-working hammer, but is often used by carpenters to strike punches, chisels and nails. |

|

|

CARPENTER'S SQUARE |

This handy little tool is used to mark out right-angles and square lines. |

|

|

COMBINATION SQUARE |

a versatile tool used for measuring and scribing right angles and parallel lines, it also serves for making mitres and as a depth gauge, height gauge and level. |

|

|

WOOD CHISELS |

are used to clean out joints and neaten up saw cuts. |

|

|

WHETSTONE |

are used to sharpen tools that have dulled over time. Keeping your tools sharp will increase your work rate. Sharp chisels are essential for clean cuts. |

|

|

CORDLESS COMBI DRILL |

will allow you to drive screws as well as drill holes. It has the advantage of being cordless so it can be used anywhere. It is interchangable, rechargeable and easy to use. |

|

|

POWER DRILL |

a drill that can take the tough jobs. |

|

|

MITRE SAW |

They are used to make quick, accurate crosscuts in a workpiece. |

|

|

CIRCULAR SAW |

is one of the most versatile power tools you can own. with the correct clamps in place can be just as accurate as a table saw. |

|

|

BENCH GRINDER |

will keep your chisels sharp, as well as remove burrs from those screwdrivers you used to pry open paint tins. |

|

|

ANGLE GRINDER |

It is used for cutting, grinding and polishing. |

|

|

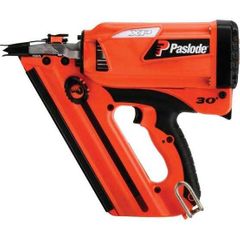

NAIL GUN |

is a powerful tool and can increase your work rate tenfold by dispensing up to 200 nails per minute. |

|

|

ELECTRIC ROUTER |

is used to rout out (hollow out) an area in the face of any timber. |

|

|

ELECTRIC PLANER |

is able to flatten, reduce the thickness of and impart a smooth surface to a rough piece of timber. |

|

|

JIG SAW |

will allow you to cut curves and patterns in your chosen material. Electric ones are more powerful than battery operated models. |

|

|

ELECTRIC PAD SANDER |

are brilliant for sanding in those tight corners and small spaces. |

|

|

TABLE PLANE |

is used to produce a flat surface along a board's length and turns rough hewn timber into neatly planed planks. |

|

|

AIR COMPRESSOR |

a device that turns power (usually from an electric or petrol motor) into kinetic energy in the form of compressed air. |

|

|

OSCILLATING MULTI-TOOL |

can start cutting at any given point on your workpiece, allowing the user to quickly, cleanly and accurately cut without wasting time drilling starter holes. |

|

|

WORKMATE / SAW HORSE / WORKBENCH |

are tools in their own right. They have adjustable surfaces and clamps, standard square edges for measuring and many other attributes. They have multiple applications, from providing somewhere to saw your timber to a place to rest your mug of tea. |

|