![]()

![]()

![]()

Use LEFT and RIGHT arrow keys to navigate between flashcards;

Use UP and DOWN arrow keys to flip the card;

H to show hint;

A reads text to speech;

271 Cards in this Set

- Front

- Back

PORTLAND CEMENT |

made from materials which must contain the proper proportions of lime, silica, alumina and iron components. |

|

|

SPECIAL CEMENTS |

● White Portland cement ● Masonry Cement ● Air-entraining Portland Cement ● Oil Well Cement ● Waterproof Portland Cement |

|

WHITE PORTLAND CEMENT |

same materials as normal Portland except in color. |

|

MASONRY CEMENT |

designed to produce better mortar than that made with normal Portland cement or with a lime-cement combination. |

|

AIR-ENTRAINING PORTLAND CEMENT |

small amounts of this is added to the clinker and ground with it to produce air-entraining cements, effective use for resistance to severe frost. |

|

OIL WELL CEMENT |

special Portland cement used for sealing oil wells. |

|

WATERPROOF PORTLAND CEMENT |

normally produced by adding a small amount of stearate, usually calcium or aluminum to the cement clinker during the final grinding. |

|

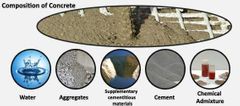

CONCRETE |

artificial stone made by binding together particles of some inert material with a paste made of cement and water. These inert materials are the aggregate. |

|

AGGREGATE |

sand, gravel crushed stone, cinder, crushed furnace slag, burned clay, expanded vermiculite, and perlite. |

|

SAND |

found in riverbeds, free of salt and must be washed |

|

FINE AGGREGATE |

smaller than ¼” diameter stones. |

|

COURSE AGGREGATE |

bigger than ¼” diameter stones. |

|

|

CLASS “AA” |

● 1:1 ½ :3 ● concrete under water, retaining walls |

|

|

CLASS A |

● 1:2:4 ● footings, columns, beams, RC slabs |

|

|

CLASS B |

● 1:2 ½:5 ● slab on fill, non load-bearing walls |

|

|

CLASS C |

● 1:3:6 ● concrete plant boxes, etc. |

|

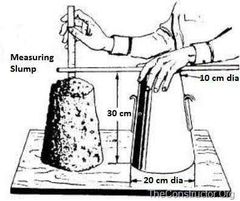

SLUMP TEST |

when freshly mixed concrete is checked to ensure that the specified slump is being attained consistently. A standard slump cone is 12 inches high (0.30) and 8 inches (0.20) in diameter at the bottom and 4 inches (0.10) on top which is open on both ends. |

|

COMPRESSIVE STRENGTH TEST |

common quality - control test of concrete, based on 7 and 28 day curing periods. |

|

CONCRETE ADDITIVES |

materials often added to the concrete or applied to the surface of freshly placed concrete to produce some special result. |

|

ACCELERATORS |

an admixture which is used to speed up the initial set of concrete. Such a material maybe added to the mix to increase the rate of early-strength development for several reasons. |

|

RETARDERS |

to delay or extend the setting time of the cement paste in concrete. |

|

|

AIR-ENTRAINING AGENTS |

air-entrained concrete contains microscopic bubbles of air formed with the aid of a group of chemical called surface active agents, materials that have the property of reducing the surface tension of water intended for use when better resistance to frost action is concerned. |

|

|

CONCRETE HARDENERS |

applied on concrete surface to increase hardiness and toughness. |

|

|

TWO TYPES OF CONCRETE HARDENERS |

● Chemical Hardeners ● Fine Metallic Aggregate |

|

|

CHEMICAL HARDENERS |

liquids containing silicofluorides or fluosilicates and a wetting agent which reduces the surface tension of the liquid and allows it to penetrate the pores of the concrete more easily. |

|

|

FINE METALLIC AGGREGATE |

are specially processed and graded iron particles which are dry-mixed with Portland cement, spread evenly over the surface of freshly floated concrete, and worked into the surface by floating. |

|

|

WATER REDUCING ADMIXTURES |

material used to reduce the amount of water necessary to produce a concrete of given consistency or to increase the slump for a given water content. |

|

|

DAMPROOFERS |

materials used to reduce or stop the penetration of moisture through the concrete. Reduces permeability. |

|

|

TWO TYPES OF BONDING AGENTS |

● Metallic Aggregate ● Synthetic Latex Emulsion |

|

|

METALLIC AGGREGATE |

iron particle are larger, but with same materials as the permeability reducer. Bonding takes place through the oxidation and subsequent expansion of the iron particles. |

|

|

SYNTHETIC LATEX EMULSION |

consists of highly polymerized synthetic liquid resin dispersed in water. |

|

|

PASTE SLURRY |

often applied to such an old surface immediately prior to pouring new concrete to increase the amount of paste. |

|

|

SET - INHIBITING AGENTS |

prevent the cement paste from bonding to the surface aggregate but will not interfere with the set throughout the remainder of the pour. |

|

|

POZZOLANIC ADMIXTURES |

materials sometimes used in structures where its desirable to avoid high temperature or in structures exposed to seawater or water containing sulfates. Pozzolans maybe added to concrete mixes-rather than substituting for part of the cement to improve workability, impermeability, and resistance to chemical attack. |

|

|

CONCRETE PRODUCTS |

made of lightweight and heavyweight materials for use in exterior and interior load-bearing walls, firewalls, curtain and panel walls, partitions etc. |

|

|

CONCRETE BLOCK |

● Hollow load-bearing concrete block ● Solid load bearing block ● Hollow; non-load bearing concrete block ● Concrete building tile ● Concrete brick |

|

|

HOLLOW LOAD - BEARING CONCRETE BLOCK |

an 8” x 8” x 16” will approximately weigh 40 to 50 lb. Made with heavyweight aggregate and 25 to 35 lb. when made with lightweight aggregate. |

|

|

SOLID LOAD BEARING BLOCK |

defines as one having a core area of not more than 25 percent of the gross cross-sectional area. |

|

|

HOLLOW; NON - LOAD BEARING CONCRETE BLOCK |

one in which the core area exceeds 25 percent of the cross-sectional area. |

|

|

COMMON SIZES |

● 4” x 8” x 16” – for non-load bearing partitions ● 6” x 8” x 16” – for load bearing walls |

|

|

QUALITY |

● Hand made ● Machine made ● Steam cured ● Cellular Concrete Blocks |

|

|

HAND MADE |

backyard industry |

|

|

MACHINE MADE |

commonly sold |

|

|

STEAM CURED |

manufactured by big and nationally known factories for load bearing walls. Usually specified for government and multi-storey buildings. |

|

|

CELLULAR CONCRETE BLOCKS |

lightweight block which is outstanding in thermal and sound insulation qualities. Basic ingredients are cement-made from silica-rich sand and lime-water, and aluminum powder. |

|

|

BRICK |

basic ingredient is clay. |

|

|

THREE PRINCIPAL FORMS |

● Surface Clay ● Shales ● Fire Clay |

|

|

SURFACE CLAY |

found near the surface of the earth |

|

|

SHALES |

clay which have been subjected to high pressure until they have become relatively hard. |

|

|

FIRE CLAY |

found at deeper levels and usually have more uniform physical and chemical qualities. |

|

|

TWO CLASSES OF CLAY |

● Calcareous Clays ● Non-calcareous Clays |

|

|

CALCAREOUS CLAYS |

contains about 15 percent calcium carbonate and burn to a yellowish color. |

|

|

NON - CALCAREOUS CLAYS |

composed of silicate of alumina, with feldspar and iron oxide. These clays burn buff, red or salmon depending on the iron oxide content which vary from 2 to 10 percent. |

|

|

STANDARD BRICK SIZE |

2 ¼ x 3 ¾ x 8 inches |

|

|

STRUCTURAL CLAY TILES |

are hollow units as opposed to brick which is sold. Tiles are made from the same material as brick, but all clay tiles are formed by extrusion in the stiff-mud process. |

|

|

TYPES OF TILES |

● Load bearing wall tile ● Partition tile ● Back-up tile ● Furring tile ● Fireproofing tile ● Floor tile ● Structural Clay Facing tile ● Structural Glazed Facing tile |

|

|

LOAD BEARING WALL TILE |

used for bearing walls of light buildings, the height usually restricted to four stories. Structural load bearing wall tile are made in 4, 6, 8, 10 and 12 in thickness. |

|

|

PARTITION TILE |

non-load bearing |

|

|

BACK - UP TILE |

intended for use in both bearing and non-bearing walls which will be faced with brick or facing tile. |

|

|

FURRING TILE |

used on the inside of exterior walls to provide air spaces for insulation to prevent the passage of moisture and to provide a suitable plastering surface. Classified as non-load bearing. |

|

|

FIREPROOFING TILE |

structural steel must be insulated in fireproof construction. One method of doing this is to cover it with fire-proofing tile. |

|

|

FLOOR TILE |

manufactured in both load-bearing and non-load bearing grades in standard thickness raging from 3 to 12 inches in standard length and widths of 12 inches. |

|

|

STRUCTURAL CLAY FACING TILE |

unglazed tile and may have either a smooth or a rough textured finish. They are designed to used as exposed facing material on either exterior or interior walls and partitions. |

|

|

STRUCTURAL GLAZED FACING TILE |

produced from high-grade light burning clay which is suitable for the application of ceramic or salt glaze. |

|

|

TERRA COTTA |

means “fired earth” is a clay product which has been used for architectural decorative purposes, since ancient Greece and Rome. Modern terracotta is machine-extruded and molded or pressed. The machine-made product is usually referred to as ceramic veneer, and is a unit with flat face and flat or ribbed back. |

|

|

TWO TYPES OF CERAMIC VENEER |

● Adhesion Type ● Anchor type |

|

|

ADHESION TYPE |

held to the wall by the bond of the mortar to the ceramic veneer back and to the backing wall. |

|

|

ANCHOR TYPE |

are held by mortar and by wire tiles between the terracotta and the wall behind. |

|

|

BUILDING STONES |

stones usually blocks or pieces of the basic material rock. |

|

|

THREE GENERAL CATEGORIES |

● Igneous ● Sedimentary ● Metamorphic

|

|

|

IGNEOUS |

formed as a result of the cooling of molten matter. |

|

|

SEDIMENTARY |

formed by the action of water either by depositing materials at the bottom of a water body or depositing them on the earth’s surface. |

|

|

METAMORPHIC |

rocks changed from their original structure by the action of extreme pressure, heat, or various combinations of these factors. |

|

|

CLASSIFIED ACCORDING TO FORM |

● Rubble ● Dimension (Cut stone) ● Flagstone (Flat slabs) ● Crushed rock

|

|

|

RUBBLE |

includes rough fieldstone which may merely have been broken into suitable sizes, or it may include irregular pieces of stone that have been roughly cut to size, usually used for and filling material. (escombro and lastillas) |

|

|

DIMENSION ( CUT STONE ) |

consists of pieces that have been cut or finished according to a set or drawing. (for facing walls) |

|

|

FLAGSTONE ( FLAT SLABS ) |

consists of thin pieces (1/2 in. and up which may or may not have had their face dimensions cut to some particular size. (for walks and floors) |

|

|

CRUSHED ROCK |

consisting of pieces varying I size from 3/8 to 6 in. and is used to a large extent in concreting. |

|

|

ASHLAR |

work requires the use of cut stone and includes broken ashlar, irregular coursed ashlar, regular coursed ashlar. |

|

|

RUBBLEWORK |

used as random when no attempt is made to produce either horizontal or vertical course lines. Small spaces are filled with spalls, small stones and used as course rubble work, horizontal course lines are maintained but no vertical course lines used. |

|

|

TRIM |

involves use of stones cut for a specific purpose and include Quoins. |

|

|

AS JAMBS |

stones which form the sides of window and door openings. |

|

|

AS SILLS |

stones which form the bottom of window and door openings. |

|

|

AS BELTS |

special stone courses which are built into a wall for a particular purpose. One reason is to provide architectural relief to a large wall of one material or to provide a break I the vertical plane of the wall, another reason is to hide a change in the wall thickness. |

|

|

AS COPINGS |

one which is cut fit on the top of a masonry wall. It prevents the passage of water into the wall, sheds water to either inside or outside, and gives a finished appearance to the wall. |

|

|

AS CORNICES |

specially cut stones which are built into and project from a masonry wall near the top to provide the appearance of a cave. |

|

|

AS LINTELS |

stones which bridge the top of door and window openings. |

|

|

AS STONE STEPS |

made to fit over an inclined concrete slab or to cap steps cast in concrete. |

|

|

AS AN ARCH STONE |

cut to form some particular type of arch over a door or window opening |

|

|

AS STONE FLOORING |

walks and patios, made by covering a base of stone concrete, brick or tile with flagstones, trimmed flagstone, trimmed rectangular and square. |

|

|

GYPSUM |

a soft mineral consisting of a hydrated calcium sulfate from w/c gypsum plaster is made (by heating); colorless when pure. |

|

|

WOOD |

a traditional building material, it is easily worked, has durability and beauty. It has great ability to absorb shocks from sudden load. In addition, wood has freedom from rust and corrosion, is comparatively light in weight, and is adaptable to countless variety of purposes. |

|

|

CLASSIFICATION OF TREES |

● Hardwoods ● Softwoods |

|

|

HARDWOODS |

‘deciduous’ trees that have broad leaves which are normally shed in the winter time. |

|

|

SOFTWOODS |

‘conifers’ trees that have needles rather than leaves and that bear their seeds in cones. |

|

|

MOISTURE CONTENT OF WOOD |

expressed as a percentage of the oven-dry weight and can be determined by the oven-dry method or by an electric-moisture meter method. |

|

|

THREE CATEGORIES OF LUMBER |

● Yard Lumber ● Shop Lumber ● Structural Lumber |

|

|

FINISHES OF WOOD |

● S1S ● S2S ● S4S ● Rough |

|

|

S1S |

surfacing or planning of one side. |

|

|

S2S |

two sides planed. |

|

|

S4S |

four sides planed. |

|

|

ROUGH |

as sawn and not planed. |

|

|

WOOD GRAIN |

● Edge Grain ● Flat Grain ● Angle Grain |

|

|

EDGE GRAIN |

annual rings run approximately at right angle to the face. |

|

|

FLAT GRAIN |

when the annual rings run more or less parallel to the surface. |

|

|

ANGLE GRAIN |

when the annual rings are at about 45 degrees to the face. |

|

|

SEASONING OF LUMBER |

● Air-Drying ● Kiln-Drying ● Pressure treated lumber

|

|

|

AIR - DRYING |

lumber is strip-piled at a slope on a solid foundation. This allows air to circulate around every piece while the sloping allows water to run off quickly. |

|

|

KILN - DRYING |

more expensive lumber which is required for more refined uses so as wood will not move, such as furniture. Flooring and general interior use. |

|

|

PRESSURE TREATED LUMBER |

when lumber is subjected to pressure and injected with chemicals or salts to insure it from rots. |

|

|

SPECIFICATION WHEN BUYING LUMBER |

Indicate no. of pieces, thickness, width, length, total bd. Ft. kind of lumber and finish. Example: 6-2” x 8” x 14’-0” = 112 bd. Ft. tanguile S4S |

|

|

GLUE LAMINATED TIMBER |

term used to describe a wooden member built up of several layers of wood whose grain directions are all substantially parallel, and held together with glue as fastening commonly used for beams, girders, posts, columns, arches, arches, bowstring truss chords, usually softwoods are commonly used because of their low cost, lightness and strength. |

|

|

GLUE USE IN LAMINATING |

● Casein glue ● Urea-formaldehyde-resin ● Phenol-formaldehyde-resin glues ● Resorcinol-phenol-formaldehyde |

|

|

CASEIN GLUE |

satisfactory for use in dry locations not exposed to rain or water. |

|

|

UREA - FORMALDEHYDE - RESIN |

cheap and well cure at from 70 degrees Fahrenheit up. Will withstand soaking in cool water. |

|

|

PHENOL - FORMALDEHYDE - RESIN GLUES |

not usually recommended because of the high temperature needed to cure them. Useful for combining timber and plywood and are very water-resistant. |

|

|

RESORCINOL - PHENOL - FORMALDEHYDE |

resin glues are expensive but have excellent qualities of durability and water resistance. |

|

|

BUILDING BOARDS |

a group of sheets of building materials often faced with paper or vinyl, suitable for use as a finished surface on walls, ceiling, etc. |

|

|

KINDS OF BUILDING BOARDS |

● Plywood ● Hardboard ● Insulating Fiberboard ● Chipboard ● Particle Board ● Gypsum Board ● Straw Board ● Asbestos-cement Board ● Corkboard ● Paperboard ● Mineral Fiberground ● Plastic Foamboards |

|

|

PLYWOOD |

made by bonding together thin layers of wood in a way that the grain of each layer is at right angles to the grain of each adjacent layer. |

|

|

VENEER |

each layer of plywood |

|

|

ROTARY CUTTING |

a method of cutting wood veneer in which a log is fixed in a lathe and rotated against a knife so that the veneer is peeled from the log in a continuous sheet. |

|

|

HARDBOARD |

made from processed wood chips. |

|

|

THREE GRADES OF BOARD |

● Standard ● Tempered hardboard ● Low-density hardboard |

|

|

STANDARD |

flexible to be quite easily bent. |

|

|

TEMPERED HARDBOARD |

made by impregnated standard board with a tempering compound of oils and resin and baking it to polymerize the tempering material. |

|

|

LOW - DENSITY HARDBOARD |

not as strong and durable as standard hardboard. |

|

|

INSULATING FIBERBOARD |

made from three types of fiber – wood, sugar cane, and asbestos, and binder, formed into a board. |

|

|

CHIPBOARD |

a large class of building board made from wood and particles and a binder, often faced with veneer. |

|

|

PARTICLE BOARD |

a hardboard made from relatively small particles. |

|

|

GYPSUM BOARD |

a wall board having a gypsum core. |

|

|

STRAW BOARD |

a hardboard made of compressed wheat straw, processed at 350 to 400 degree Fahrenheit and covered with a tough kraft paper. |

|

|

ASBESTOS - CEMENT BOARD |

a dense, rigid board containing a high proportion of asbestos fibers bonded with Portland cement, resistant to fire, flame, and weathering, has low resistance to heat flow. |

|

|

CORKBOARD |

from the outer bark of the cork oak tree, cork granules is mixed with synthetic resin, compressed and formed into sheet from 1 to 6 inches thick and baked under pressure into rigid boards. |

|

|

PAPERBOARD |

made into two different types: a paper pulp pressed into boards 3/16, or ¼ in. thick, 4 ft. wide, and 6, 7 or 8 ft. long. Usually one surface is primed for easier finishing. The other is a layer of stiff paper folded into corrugated from and faced on both sides with a thick paper backing, cemented to the core. |

|

|

MINERAL FIBERGROUND |

thick mats of mineral fibers, usually glass or rock wool are covered with a backing of stiff paper on one or both sides to form rigid boards, ranging in thickness from ½ to 2 in. The usual board size is 24 x 48 inches. |

|

|

PLASTIC FOAMBOARDS |

polystrene and polyurethane plastics are formed by a patented process to about 40 times their original volume. Used for perimeter insulation for concrete floor slabs, for wall and roof deck insulation, and for roof decks when properly supported. |

|

|

BUILDING PAPERS |

in building construction, paper is used for sheathing, roofing and insulation, in making asphalt shingles, laminated and corrugated building products, and concrete form materials, as a moisture and vapor barrier; as cushioning material; as wallpaper; as an envelope or sheath for other materials; and as a fireproofing material. |

|

|

TYPE OF WOOD PULP |

● Mechanical Pulp ● Chemical Pulp ● Semi-chemical Pulp |

|

|

MECHANICAL PULP |

or groundwood, is produced by grinding blocks of wood against a revolving abrasive stone or by grinding steamed wood chips in a grinding mill. |

|

|

CHEMICAL PULP |

produced by digesting wood chips in various chemicals to free the cellulose fibers from the liquid binding. |

|

|

SEMI - CHEMICAL PULP |

wood chips are first subjected to a mild chemical treatment and then mechanically disintegrated in rotating disk refiners. |

|

|

TYPES OF PAPER |

● Sheathing Paper ● Roofing Paper ● Insulating Paper ● Cushioning Paper ● Vapor Barrier Paper ● Laminating Paper ● Concrete Form Paper ● Wallpaper ● Envelope Paper ● Fire Proofing Paper |

|

|

SHEATHING PAPER |

used to provide an airtight barrier over walls, floors, etc. |

|

|

ROOFING PAPER |

● Roofing Felts – used in making a built-up roof and are usually produced in 36 in. wide rolls, in various weights from 3 to 20 lb/square. ● Rolled Roofing – a heavy, mineral surfaced paper used as a final roof covering, made 18 and 36 in. wide, in various weights from 45 to 120 lb/square. |

|

|

INSULATING PAPER |

used to secure bulk and entrapped air with as much strength as possible. Insulating papers are made from both wood-fiber insulating paper and asbestos fibers. |

|

|

CUSHIONING PAPER |

similar to wood-fiber insulating paper, but less attention is paid to strength. Its chief use is for cushioning under linoleum, carpets, or slate roofing. |

|

|

VAPOR BARRIER PAPER |

intended to prevent the passage of moisture vapor through walls, ceilings and floors. |

|

|

LAMINATING PAPER |

a special, high strength kraft paper made for use in the production of plastic laminates. The thin, strong paper is impregnated with liquid plastic resin and several sheet are laminated together under heat and pressure to form the base for the plastic sheet. |

|

|

CONCRETE FORM PAPER |

made from strong kraft paper in the form of a spiral tube and boxlike from made from corrugated container paper. |

|

|

WALLPAPER |

paper from which decorative wallpaper is made. |

|

|

ENVELOPE PAPER |

used as an outer covering or envelope for a number of building materials. One of these is gypsum board, composed of a layer of calcined gypsum covered in both sides by a sheet of kraft paper. |

|

|

FIRE PROOFING PAPER |

made from asbestos fibers, since this is an incombustible material. This material maybe in the form of matted paper, similar to asbestos insulating or roofing paper, or it may be in the form of a cloth woven from thread spun from asbestos fibers. |

|

|

BITUMEN |

a generic name applied to a semisolid mixture of complex hydrocarbons, derived from coal or petroleum, as a coal-tar pitch or asphalt. |

|

|

TAR |

the resulting condensate when destructive distillation is carried out on such materials as wood coal, shale, peat or bone. |

|

|

PITCH |

a solid or semi-solid residue produced from partial evaporation or fractional distillation of tar. |

|

|

COAL - TAR PITCH |

most common material of this kind of pitch. |

|

|

ASPHALTS |

dark brown or black solids or semi-solids which are found in the natural state and are also produced by the refining of petroleum. |

|

|

LIQUID PAVING ASPHALTS |

liquid asphalts used for paving are cutbacks. |

|

|

ASPHALT PAVING CEMENTS |

used as binders for more expensive asphalt pavements. |

|

|

FERROUS METALS |

● Steel ● Pig Iron ● Wrought Iron ● Alloy Steels ● Nickel Steel ● Stainless Steels ● Copper ● Manganese Steel ● Weathering Steel |

|

|

STEEL |

a malleable alloy of iron and carbon produced by melting and refining pig iron and/or scrap steel, graded according to the carbon content. |

|

|

PIG IRON |

used to make cast iron which is high in compressive strength but low in tensile strength, and has little use for construction |

|

|

WROUGHT IRON |

produced when pig iron is melted in such a way as to remove nearly all of the carbon and other impurities. |

|

|

ALLOY STEELS |

made by containing other elements with the molten steel. Nickel, chromium copper and manganese are used. |

|

|

NICKEL STEEL |

stronger than carbon steel and is used to make structural members for building chromium steel is very hard and corrosion-resistant. |

|

|

STAINLESS STEELS |

made with chromium or a combination of nickel and chromium used in buildings for exterior wall panels, frames for doors, expansion joints, flashings, copings, fascia and gravel stops. |

|

|

COPPER |

bearing steel has high resistance to corrosion and is used for making sheet steel and metal lath. |

|

|

MANGANESE STEEL |

offers great resistance to abrasion and finds important use in the cutting edges of heavy digging tools. |

|

|

WEATHERING STEEL |

recently developed grade of steel. It forms its protection against atmospheric corrosion and thus requires no painting. |

|

|

NONFERROUS METAL |

● Aluminum ● Aluminum Foil ● Copper ● Lead ● Tin |

|

|

ALUMINUM |

a lustrous, silver-white nonmagnetic, lightweight metal which is very malleable; has good thermal and electrical conductivity; a good reflector of both heat and light. |

|

|

ALUMINUM FOIL |

used as a vapor barrier on walls and ceilings and as reflective insulation. |

|

|

COPPER |

a lustrous reddish metal, highly ductile and malleable; has high tensile strength; is an excellent electrical and thermal conductor; is available in a wide variety of shapes; widely used for downspout, electrical conductors, flashings, gutter, roofing, etc. |

|

|

LEAD |

a soft, malleable, heavy metal; has low melting point and a high coefficient of thermal expansion. Very easy to cut and work, enabling it to be fitted over uneven surfaces. Used for roofing, flashing and spandrel wall panels. |

|

|

TIN |

a lustrous white, soft and malleable metal having a low melting point; relatively unaffected by exposure to air; used for making alloys and solder and in coating sheet metal. |

|

|

GLASS |

a hard, brittle inorganic substance, ordinarily transparent or translucent; produced by melting a mixture of silica, a flux and a stabilizer. |

|

|

TYPES OF GLASS |

● Reflective Glass ● Rolled and Rough Cast Glass ● Cathedral and Figured Glass ● Wired Glass ● Heat –Absorbing Plate Glass ● Tempered Plate Glass ● Vitreous Colored Plate ● Laminated Safety Glass (Bullet Proofing) ● Insulating Glass |

|

|

REFLECTIVE GLASS |

used to control glare and reduce solar heat. It the product of a glass-coating process which is carried out in a large, rectangular vacuum chamber. Manufactured in two types, silver and gold, the glass can be specified in any one of three nominal light transmittance of 8, 14, or 20 percent. |

|

|

ROLLED AND ROUGH CAST GLASS |

used where clear vision is not required, such as by factory roofs and walls, windows for halls and staircases, skylights, and partitions in offices. Cast glass diffuses light, and because of its low reflecting and absorption index, transmits 90 to 93 percent of light rays striking it. |

|

|

CATHEDRAL AND FIGURED GLASS |

manufacturing is similar to rolled and rough-cast glasses. However, they contain a pattern or texture impressed usually on one surface by a patterned roller. |

|

|

WIRED GLASS |

simply a rolled glass into which wire mesh is inserted during the process of manufacture. |

|

|

HEAT – ABSORB8NG PLATE GLASS |

made by adding ingredients to the mix used in making regular slate glass so that the finished product is pale bluish-green or gray. |

|

|

TEMPERED PLATE GLASS |

three to five times as strong as regular plate of the same thickness – and area in resisting compressive forces and fracture due to strain or thermal shock. |

|

|

VITREOUS COLORED PLATE |

polished plate glass can be heat-strengthened and coated on one side with vitreous color which is fire-fused to the surface. |

|

|

LAMINATED SAFETY GLASS ( BULLET PROOFING ) |

widely used in the automotive industry and transportation, but now finding some uses in the building industry, like glass that can withstand firearm attack and explosions. |

|

|

INSULATING GLASS |

consists of two sheets of plate or sheet glass, separated by an air space, and joined around the edges to produce a hermitically sealed unit. |

|

|

CLASSIFICATION OF SHEET GLASS |

● Window Glass ● Heavy Sheet Glass ● Picture Glass |

|

|

WINDOW GLASS |

used for glazing windows doors and storm sash in residential buildings where good light and vision are required at moderate cost. |

|

|

HEAVY SHEET GLASS |

used for glazing windows and doors where greater strength is required but where slight distortion is not objectionable. |

|

|

PICTURE GLASS |

used for covering pictures, photographs, maps, charts projector slides and instrument dials. |

|

|

GLASS PRODUCTS |

● Glass Blocks ● Solid Glass Brick |

|

|

GLASS BLOCKS |

comparable in many ways to unit masonry but have the added feature of transmitting light. |

|

|

SOLID GLASS BRICK |

also made to admit light into a building, because of its solid construction, it offers greater protection against vandalism than conventional window glass or glass blocks. The ability of the brick is to allow undistorted passage of light. |

|

|

PLASTICS |

a large group of synthetic materials which are made from a number of common substances such as coal, salt, oil. Natural gas, cotton, wood and water. From these, relatively simple chemicals known as monomers, which are capable of reacting with one another are produced. These are then built up into chain-like molecules of high molecular weight called polymers. |

|

|

TWO GENERAL CLASSIFICATION |

● Thermoplastics ● Thermosetting Plastics |

|

|

THERMOPLASTICS |

become soft when heated and hard when cooled,regardless of the number of times the process is repeated. Include in the thermoplastics are acrylic cellulosis, polyethylene, polyvinyl chloride (PVC) polysterene, polyallomers polycarbonates, polyimide, polypropylene, polysulfone, phenylene oxide, nylons, methyl pertenes, ionomer, fluoroplastics, acetal and acryonitrile butadieniene styrene (ABS). |

|

|

THERMOSETTING PLASTICS |

set into a permanent shape when heat and pressure are applied to them during the forming stage. Thermosetting group includes phenolics, aminos (urea and melamine) epoxies, polyesters, polyurethane, alkyd silicones and diallyl phthalate (DAP). |

|

|

PRODUCTION: PLASTICS PRODUCTS ARE FORMED BY A NUMBER OF METHODS WHICH INCLUDE |

● Injection Molding Process ● Blow-Molding Process ● Rotational Molding ● Expandable Bead Molding ● Compression Molding ● Transfer Molding ● Foamed Plastics ● Thermoset Foam ● Extrusion Forming ● Thermoforming Process ● Laminating Process ● Casting ● Calendaring Process ● Plastic Laminates |

|

|

INJECTION MOLDING PROCESS |

measured amount of powder or granules is heated and when flowing forced through the nozzle of the barrel into a shaped cavity, where it cools of solidities. |

|

|

BLOW - MOLDING PROCESS |

an extruder extrudes a hollow tube which is captured between the two halves of a hollow. As the mold closes, air is blown into the tube and expand it to fit inside surface of the mold. |

|

|

ROTATIONAL MOLDING |

used to form hollow units with complex shapes and heavy walls, a premeasured amount of powder or liquid resin is placed at the bottom half of a cold mold which is then closed. |

|

|

EXPANDABLE BEAD MOLDING |

a process used to produce light weight products of polysterene foam, small granules of polysterene with a small amount of an expanding agent are placed in a rolling drum and steam heated. |

|

|

COMPRESSION MOLDING |

a measured quantity of powder in a heated mold, which is then closed. Heat and pressure are applied to the powder which melts and flows to all parts of the mold. |

|

|

TRANSFER MOLDING |

similar to compression molding except that the powder is heated and liquefied outside the mold and injected into the mold under heat and pressure, where the forming and setting takes place. |

|

|

FOAMED PLASTICS |

are made by expanding agent with either granules or powder and then heating. Heat melts the plastic and causes the formation of a gas which expands the molten material into foamed structure. |

|

|

THERMOSET FOAM |

made by mixing the appropriate resin with a curing agent and an expanding agent and then heating them in a mold. |

|

|

EXTRUSION FORMING |

used for mass-produced materials which have a constant cross section, and it is done in two ways by forcing of semi-liquid plastic through a die of the proper size and shape in a manner similar to that used for forming brick by extrusion. |

|

|

THERMOFORMING PROCESS |

sheet plastic is heated until soft and then forced by air pressure against a cold and hardens in shape. |

|

|

LAMINATING PROCESS |

consists of impregnating sheets of paper, glass fiber, or cloth with a thermosetting liquid resin and then applying heat and pressure to a number of sheets to form a laminated product. |

|

|

CASTING |

a simple process in which liquid plastics, with their appropriate curing agent, are poured into molds and set, with or without heat. |

|

|

CALENDARING PROCESS |

plastic is fed to revolving rollers which turn out a thin sheet or film the thickness of the product is determined by the roller spacing, and the surface of the sheet may be smooth or matted, depending on the roller surface. |

|

|

PLASTIC LAMINATES |

consists of three or more layers of material bonded or laminated together with plastic adhesive under high pressure. |

|

|

COHESIVENESS |

the ability of particles of a material to cling tightly to one another. |

|

|

ADHESIVENESS |

the ability of a material to fix itself and cling to an entirely different material. |

|

|

SEALERS |

products which are used to seal the surface of various materials against the penetration of water or other liquids or in some cases to prevent the escape of water through the surface. |

|

|

THREE WAYS OF HEAT TRANSFER |

● Conduction ● Radiation ● Convection |

|

|

CONDUCTION |

the inside of a concrete wall which has one side exposed to outside winter temperatures feels cold to the touch. Heat is being conducted from the side of higher temperature to that lower temperature. |

|

|

RADIATION |

from this point, it is transferred to the outside air by radiation. |

|

|

CONVECTION |

when air is heated, it expands and begins to circulate, during the circulation it comes in contact with cooler surface, some of its heat is given up to them. It is therefore important to try to prevent air currents from being set up in the walls and ceiling of our buildings. |

|

|

KINDS OF THERMAL INSULATION |

● Loose Fill ● Blanket Insulation ● Batts ● Structural Insulation Board ● Block or Rigid Slab Insulation ● Reflective Insulation ● Foamed-In-Place Insulation ● Sprayed-on-Insulations ● Corrugated Insulation |

|

|

LOOSE FILL |

● Fibrous type ● Granular insulation ● Fibrous loose fill ● Granules |

|

|

FIBROUS TYPE |

made from mineral woolrock wool, glass wool, or slag wool – or vegetable fiber – usually wood fiber. |

|

|

GRANULAR INSULATION |

made from expanded minerals such as perlite and vermaculite or from ground vegetable matter such as granulated cork. |

|

|

FIBROUS LOOSE FILL |

used to insulate walls of buildings that have been built without insulation. |

|

|

GRANULES |

are graded into four sizes, 1, (3/8 in. to no. 16 sieve) and sizes 2 (no. 4 to no. 30 sieve) used as loose-fill insulation for sidewalls and ceilings over suspended ceilings, between wood sleepers over a concrete floor slab, as fill for the cores of concrete blocks, and sizes 3 (no. 8 to no. 100 sieve) size 4 (no. 16 to 100 sieve). |

|

|

BLANKET INSULATION |

made from some fibrous materials such as mineral wool, wood fiber, cotton fiber, or animal hair, manufactured in the form of a mat, 16, 20 or 24 in. width, in 8 ft. lengths or put up in rolls of from 40 to 100 linear feet, with controlled thickness of 1, ½, 2, 3 and 4 inches. |

|

|

BATTS |

similar to blankets but they are restricted to 48 inches in long or less they are always covered with paper, and made especially for installation between stud spacings. |

|

|

STRUCTURAL INSULATION BOARD |

made from organic fiber-wood, cane, straw or cork. The wood and cane raw material is first pulped, after which it is treated with water proofing chemicals. ● Strawboard ● Corkboard |

|

|

STRAWBOARD |

made from carefully selected straw, fused under heat and pressure into a panel 2 inches thick and 4 ft. wide. |

|

|

CORKBOARD |

made from granulated cork mixed with resin and pressed into sheets of several thickness, depending on the use to which they will be put. |

|

|

BLOCK OR RIGID SLAB INSULATION |

type of insulation is so called because the units are relatively stiff and inelastic. In most cases inorganic materials are used in their manufactures. |

|

|

REFLECTIVE INSULATION |

made from such materials as aluminum or copper foil or sheet metal, with bright surfaces that reflect heat rather than absorbing it. |

|

|

FOAMED - IN - PLACE INSULATION |

this is polyurethane product made by combining a polyisocyanate and a polyester resin. |

|

|

SPRAYED - ON - INSULATIONS |

materials used are polyurethane foam asbestos fiber mixed with inorganic binders, vermiculite aggregate with a binder such as Portland cement or gypsum and perlite aggregate using gypsum as binders. |

|

|

CORRUGATED INSULATION |

usually made from paper foamed into shapes that produce enclosed air pockets. One type is produced by shaping heavy paper into a series of small regular semicircular corrugations and covering a both sides with a sheet of flat paper to give strength and produce the air pockets. |

|

|

WATERPROOFING |

a method of protecting surfaces against the destructive effects of water |

|

|

DAMP - PROOFING |

protection from the outside is provided by water repellent materials which turn water aside and force it to return to the earth. |

|

|

SOIL POISONING |

it is important to poison the soil against anay in order to stop the anay from infesting the main posts, walls and flooring. |

|

|

WOOD PRESERVATIVE |

a chemical liquid painted and applied to lumber to preserve it for years. It protects wood against powder post beatles (buk-bok), powder post termite (unos), decay causing fungi such as sap stain and dry rot. |

|

|

FIRE - PROOFING |

a clear liquid applied easily on wood, plywood, lumber and other board that retains the natural beauty, gives added strength and protects materials against fire, weather, decay, insects and warping. |

|

|

RATPROOFING |

a method of protecting rooms against the intrusion of rats and other small destructive animals from gnawing the wooden parts of the house, habitating on ceilings and floors of houses and buildings. |

|

|

RUSTPROOFING |

a method of protecting the ferrous materials like steel, iron from rusting or corrosion. |

|

|

THOROSEAL |

a cement-based, heavy-duty, easy to apply, water proof sealant and coating. Thoroseal is ideal for basement walls. |

|

|

VAPOR BARRIERS |

are materials which effectively retard or stop the flow of water vapor and normally are produced in sheets or thin layers. |

|

|

PAINT |

a mixture consisting of vehicles or binders, with or without coloring pigments, adjusted and diluted with correct amounts and types of additives and thinners, which when applied on a surface, forms an adherent continuous film which provides protection, decoration, sanitation, identification and other functional properties. |

|

|

COMPONENTS OF AN OIL BASE PAINT ARE |

● BODY ● VEHICLE ● PIGMENT ● THINNERS ● DRIERS ● VARNISHES ● ENAMELS ● SHELLAC ● LACQUERS ● STAINS ● FILLERS ● SEALERS ● SILICONE WATER REPELLANT |

|

|

BODY |

that solid, finely ground material which gives a paint the powder to hide, as well as color a surface. |

|

|

VEHICLE |

a nonvolatile fluid in which the solid body material is suspended. The vehicle should consists of from 85 to 90 percent drying oil and the remainder thinner and drier. |

|

|

PIGMENT |

material which give the paint its color. |

|

|

THINNERS |

are volatile solvents, materials which have a natural affinity for the vehicle in the paint. They cause the paint to flow better. Most common thinner is turpentine. |

|

|

DRIERS |

organic salts of various metals such as iron, zinc, cobalt, lead manganese, and calcium, which are added to the paint to accelerate the oxidation and hardening of the vehicle. |

|

|

VARNISHES |

a group pf more-or-less transparent liquids which are used to provide a protective surface coating, at the same time they allow the original surface to show but add a lustrous and glossy finish to it. |

|

|

ENAMELS |

when pigment is added to a varnish, the result is enamel. |

|

|

SHELLAC |

the only liquid protective coating containing a resin of animal origin. The resin is an exudation of the lac insect of India and Southeast Asia, deposited on the branches of the tree. |

|

|

LACQUERS |

a new product made from synthetic materials to take the place of varnish for clear finishes. The ingredients are dissolved in a mixture of volatile solvents which evaporate, leaving a film to form the protective coating. When another class of material, “pigments” are added to clear lacquer, the result is lacquer enamel, available in wide range of colors. |

|

|

STAINS |

materials used to apply color to wood surfaces. They are intended to impart color without concealing or obscuring the grain and not to provide a protective coating. |

|

|

FILLERS |

are finishing materials which are used on wood surfaces, particularly those with open grain, to fill the pores and provide a perfect smooth, uniform surface for varnish or lacquer. It is also used to impart color to the wood pores and so emphasize the grain. |

|

|

SEALERS |

to seal the surface of the wood and prevent the absorption of succeeding finish coats. It may be applied to bare wood in essentially the same way as paste filler but has much less filling capacity. |

|

|

SILICONE WATER REPELLANT |

used on all non-painted concrete, synthetic finishes, rubble, brick, and wash-out finishes as a protection from absorption of water and prevent moss, alkali, fungi to destroy the surface. |

|

|

BUILDING STONES |

● Argilite ● Granite ● Limestone ● Travertine ● Marble ● Serpentine ● Sandstone ● Slate rock |

|

|

ARGILITE |

one formed d\from clay, commonly dark-blue with faint shades of green, used for floor tile, stair treads, coping stones, interior wall base, interior window stools of exterior window sills. |

|

|

GRANITE |

igneous origin and composed of quartz, feldspar, hornblende and mica. Its generally very hard, strong durable and capable of taking a high polish. |

|

|

LIMESTONE |

a sedimentary rock which is either oolitic, or calcite cemented calcareous stone formed of shells fragments, particularly non-crystalline in nature, it has no cleavage lines and uniform in structure and composition. |

|

|

TRAVERTINE |

a sedimentary rock, composed mainly of calcium carbonate. It has been formed at the earth’s surface through the evaporation of water from hot springs. |

|

|

MARBLE |

metamorphic rock, one that has been changed from its original structure in this case, limestone and dolomite have been recrystallized to form marble. |

|

|

SERPENTINE |

igneous rock with the mineral serpentine. The mineral is olive green to greenish black, but impurities may give the rock other colors. |

|

|

SANDSTONE |

a class of rock composed of cemented silica grains. Colors include gray, buff, light brown and red. |

|

|

SLATE ROCK |

formed by metamorphosis of clays and shales deposited in layers. A unique characteristic of the rock is the relative ease with which it may be separated into thin tough sheets, called slates, ¼” or more thick. |

|

|

STONE CONSTRUCTION |

● Paneling ● Ashlar ● Rubblework ● Trim |

|

|

PANELING |

consists of using slabs of stone cut to dimension and thickness to cover backup walls and provide a finished exterior. |