![]()

![]()

![]()

Use LEFT and RIGHT arrow keys to navigate between flashcards;

Use UP and DOWN arrow keys to flip the card;

H to show hint;

A reads text to speech;

137 Cards in this Set

- Front

- Back

|

These devices can start, stop and regulate the volume of flow, prevent fluids passing the wrong way through a pipeline system (backflow) and regulate to relieve pressure. |

Valves |

|

|

These valves have a tapered or non-tapered plug running vertically through the body of the valve |

Plug valves |

|

|

Plug valves are generally considered to be quarter turn valves, which means? |

The tapered plug can only be turned 90deg to stop or start flow through the pipe |

|

|

What are valves used to control |

The flow of the fluids through the pipe network |

|

|

What is are slurries? |

Liquids containing suspended solids |

|

|

What are some applications plug valves can be used in |

Gas and liquid fuel Extreme temperatures Liquids containing slurries |

|

|

What plug valve designs allow for less piping and fewer valves to control direction of flow |

Multi-port design |

|

|

Which plug valves require powered actuators |

4" NPS and over |

|

|

Name 3 advantages of plug valves |

1. Simple design with few parts 2. Quick to open or close 3. They can be serviced in place |

|

|

Why do plug valves require more force to turn |

High friction between the plug and the valve barrel |

|

|

What is more expensive? The plug valve or ball valve? |

Plug Valve |

|

|

These valves are recommended to be used in the fully open or fully closed position and should never be used to throttle the flow of liquids |

Gate Valves |

|

|

Why should you not have a slightly open position on a gate valve |

It will cause high velocity flow through the valve and enhance wire drawing and erosion on the disc and the valve seating |

|

|

This valve is good for being shutoff for long periods of time |

Gate Valves |

|

|

The gate valve minimizes the pressure drop in this position |

Fully open position |

|

|

Why are gate valves good for applications involving slurries and viscous liquids |

The gates knife can cut right through the slurry |

|

|

These valves are used in vacuum system designed for material transport |

Gate Valves |

|

|

These gate valves are slow opening and slow closing valves |

Threaded stem gate valve |

|

|

Name a disadvantage of gate valves |

They are not optimal in applications that require cleanliness or sanitary conditions |

|

|

Why do rising stem gate valves require extra clearance above the valve stem |

To allow room for the stem to project to it's full length when the valve is open |

|

|

These valves are not recommended where shock loading may occur |

Gate valves |

|

|

What applications are globe valves installed in |

Throttling applications |

|

|

How many turns does he fluid need to make to get through the globe valve |

Nearly 4, 90deg turns |

|

|

What is an advantage of globe valves |

The require fewer turns to open and close |

|

|

What configurations are globe valves available in? |

Straight, Y and angle |

|

|

What are self-scouring seats designed for on Y and angle pattern globe valves |

Use in blow off or blowddown service where mud or sludge has to be removed from a vessel |

|

|

What are the disadvantages of globe valves |

1. They have a high-pressure drop compared to valves with a straigh-through flow pattern 2. They need greater force to hold the disc against the seat when the line pressure is working to push the disc open |

|

|

Is it hard to machine or resurface valve seats and to replace the disc or seats in the appropriate valve models |

No, its easy |

|

|

How do ball valves differ from plug valves |

The ball valve uses a spherical ball that seats against seating rings |

|

|

What is a similarity of ball valves and plug valves |

They both only require a 90deg turn to open and close it |

|

|

Which are smaller, ball valves or gate valves? |

Ball valves |

|

|

Name 3 advantages of ball valves |

1. Provide bubble tight closure 2. Quick to open or close 3. Can be used in both clean fluids and in slurry applications |

|

|

What does a multi-port ball valve design allow for? |

Less piping and fewer valves to control direction of flow |

|

|

Which require least amount of force to actuate the valve. Ball, gate or glove valve? |

Ball valve |

|

|

Name the disadvantages of ball valves |

1. They are not suitable for sustained periods of throttling 2. Sharp particulate matter can settle or be trapped in the body cavities and wear, leakage or valve failure |

|

|

Why are ball valves becoming the most common valve used in all flow control applications today? |

Because of its laminar flow conditions and operation capabilities |

|

|

Although the two valves are similar. What is the difference between butterfly and gate valve? |

The butterfly valve disc rotates in the bore of the valve |

|

|

What sizes are gate valves available in |

1-1/2" to 200" |

|

|

T/F. Butterfly valves are compact and require minimum space for installation in a line? |

True |

|

|

What is the turn capability of the butterfly valve |

1/4 turn |

|

|

When to butterfly valves achieve 100% shutoff |

When the disc is at right angles to the flow of fluids |

|

|

These valves discs are designed for throttling and offer little or no resistance when full open |

Butterfly Valve |

|

|

What angles are throttling applications restricted to on butterfly valves |

Between 30 and 80 degree disc openings |

|

|

What are butterfly valves prone to when used for throttling |

Cavitation or choked flow |

|

|

What is the check valve used for |

To prevent backflow or reverse flow within the piping system. |

|

|

What does the check valve rely on to close |

Pressure, gravity and the weight of the disc |

|

|

How does the check valve work |

The proper direction of flow opens the valve and a reverse direction of flow forces the valve closed. The valve will reopen when the flow return to normal |

|

|

This type of valve does not have a stuffing box |

Diaphragm valve |

|

|

What does a diaphragm valve use to seal the fluids from the valve stem |

A flexible diaphragm |

|

|

Why do diaphragm valves have a good chemical resistance |

Large variety of materials available for the liners and diaphragm |

|

|

What are straight through type of diaphragm valves excellent for? |

Use with sludge, slurries and other viscous fluids |

|

|

What is the Wier design diaphragm valve best used for |

General-use applications or for tough corrosive and abrasive services |

|

|

What are diaphragm valves suitable for |

Hazardous chemical and radioactive fluid services. Food processing, pharmaceutical and other material processing where atmospheric contamination cannot be allowed |

|

|

What might Weir-type diaphragm valves prevent |

Drainage of the piping |

|

|

When my diaphragm erode quickly on a diaphragm valve |

If used for severe throttling of sludge or slurries |

|

|

Why are design variation required for valves. |

Specific application requirements, space limitations, contents being carried within the piping or desired flow characteristics within the piping system |

|

|

Plug valves have long been associated with this aspect of the industry |

Gasfitting aspect |

|

|

This variation of plug valve can be locked in the off position |

Lockable service valve and insulated service valve (luboseal) |

|

|

Where is the lockable service valve put on the natural gas service line. |

Upstream of the meter |

|

|

What is the most common gas valve used today on an outside installation |

Insulated Service Valve (Luboseal) |

|

|

What is the insulated union attached to the Luboseal valves purposes |

1. Provides a barrier between the underground and building piping 2. It provides a method for 2 piping systems to attach together |

|

|

The gas code requires that all appliances must be furnished with this. |

A gas valve |

|

|

What is a gas valve normally made from |

Yellow brass |

|

|

This valve is used on gas appliances as a firing valve between the gas controls and the gas burner or as an appliance valve ( before the gas controls) |

Firing valve or appliance valve |

|

|

The pilot valve is a.... |

Small sized valve used on pilot gas supplies |

|

|

What type of thread is the inlet on a corporation stop valve |

AWWA thread |

|

|

What is the outlet of the corporation stop valve |

Flared union got copper water tube |

|

|

What most corporation valves be made of |

Red brass or bronze |

|

|

Where is the curb stop installed |

The private property boundary line |

|

|

What is similar to a gas valve but used as a balancing control on hot water heating systems |

Square-headed steam cock valve |

|

|

These valves have one threaded end and the other is for rubber hose connections |

Pet cock valve |

|

|

What is the most important variation in the gate valve design |

The type of disc that is used |

|

|

What are the 4 main types of disc designs for gate valves |

1. Solid wedge disc 2. Flexible wedge disc 3. Split wedge disc 4. Double disc |

|

|

What is the most widely used gate valve |

The solid wedge disc valve |

|

|

What is the solid wedge disc valve suitable for |

Steam, hot and cold water, oil, air or gas service conditions |

|

|

Why is the the solid wedge disc valve ideal for turbulent flow condition? |

There are no loose internal parts to vibrate and wear. |

|

|

Why do use the flexible wedge disc instead of the solid wedge disc valve |

The solid wedge disc valve pinches in the closed position due to the valve body contracting more than the disc in cool conditions |

|

|

What gives the flexible wedge disc that degree of flexibility |

Its hollow around the edges and solid across the centre portion |

|

|

The gate valve disc variation consists of two pieces that sit between two matching tapered seats in the body |

Split wedge disc |

|

|

What is used to open and close the split wedge disc gate valve |

A simple spreader mechanism |

|

|

What is the split wedge disc gate valve most suited for |

Service conditions where laminate flow of the fluid is prevalent |

|

|

Where should split wedge gate valves not be used |

Where there is a turbulent flow or fluid as the vibrations will wear the internal mechanisms |

|

|

In this valve the disc and seat are parallel to each other and are not tapered |

Double disc valve |

|

|

When the double disc gate valve is open this happens |

The spreader mechanism releases its pressure and the two discs move away from the seats before they start to rise |

|

|

What is the other version of gate valve that opens and closes quickly |

Quick opening gate valve |

|

|

Why use straight patter globe valve on a straight run instead of a gate valve |

More flow restriction |

|

|

What are straight patter globe valves specifically used for |

Adjustment or throttling of flow |

|

|

Where is an angle pattern globe valve used |

Where the pipe turn through 90deg |

|

|

Where are Y pattern globe valves used |

Straight runs of pipe where the pressure loss must be kept to a minimum or where there is a possibility of sediment being deposited in the line upstream of the valve (steam boiler blow downs) |

|

|

Where are Y pattern globe valves used |

Straight runs of pipe where the pressure loss must be kept to a minimum or where there is a possibility of sediment being deposited in the line upstream of the valve (steam boiler blow downs) |

|

|

What are 4 main types of globe valve seats and disc designs |

1. Plug disc valve 2. Conventional disc valve 3. Composition discs 4. Needle valves |

|

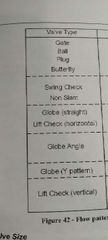

What are the flow patterns of these valve types |

|

|

|

what is an actuator |

a device that operates a valve. It is designed to open, close or regulate flow through a valve that is difficult to turn with a normal handle or in a location that is difficult to reach |

|

|

what is a sprocket and chain actuator used for |

convenient, remote operation of gate or globe valves in overhead locations that are not easily accessible |

|

|

this manual actuator is a gear arrangement that provides a mechanical advantage which allows for easy opening and closing of the valve |

Bevel and Spur Gearing |

|

|

Can actuators be power actuated |

yes |

|

|

what does the valve comprise of? |

the body the bonnet (cover) the disc the pressure-sealing connection between the body and the bonnet |

|

|

what does the valve body do |

directs the fluid flow through the valve and provides the mountings for internal parts of a valve

|

|

|

what is mounted onto the valve body to complete the pressure casing |

the valve bonnet |

|

|

for these valves the bonnet houses and opening through which the valve stem passes |

gate, globe, stop check and diaphragm valves |

|

|

what might the valve bonnet have to prevent the process fluid from migrating out along the valve stem |

a stuffing box or packing gland area |

|

|

what are mounted on the valve bonnet |

the upper works, such as the yoke or other operating mechanisms that acts to move the valve stem

|

|

|

what is the most common design for bonnets used on larger high pressure valves

|

the bolted bonnet |

|

|

what does the valve disc do |

controls the flow through the valve body |

|

|

why is the disc considered part of the pressure casing |

because it is under the same line pressure as the valve body and then bonnet when the valve is in the closed position |

|

|

how does water run through a ball valve |

a hole is drilled through the centre of the ball and a slot is cut into one side of the ball at 90deg to the run of the hole to rotate the ball |

|

|

what is a trunnion ball valve |

uses a cylinder shape on opposite sides on the that mount the ball with a set of bearings, reducing the thrust required to rotate the ball |

|

|

what are the 3 main parts of the plug valve

|

1. body 2. cover 3. plug |

|

|

what does rectangular port mean |

the valves have rectangular ports through the plug and body. |

|

|

when talking about 100% area or full port what does it mean

|

the area through the valve is equal to or greater then the area of standard pipe |

|

|

standard opening means? |

the area through the valve is less than the area of standard pipe. these valves should only be used where restriction of flow is unimportant |

|

|

when the valve has a full round opening through the plug and body, of the same size and area as standard pipe it is refered to as? |

round port |

|

|

this valve uses a tapered plug with mechanical lifting device that unseats the plug before it is turned to reduce the operating torque required, Or, it may have an elastomeric sleeve or plug coating with a low coefficient of rubbing friction |

non-lubricated plug valves |

|

|

this actuator is used for service where the valve is normally in the open position |

air-to-close actuator |

|

|

what is the valve trim |

the seats, discs, glands, guides, spacers, bushings and springs used inside some valve models that are replaceable |

|

|

T/F. Valve trim is made from the same material as the body, bonnet, stem or packing |

False, different items of trim are subject to different forces and condition, so different material is needed to accomodate |

|

|

What is the name of a type of needle valve used on steam boilers to determine the water level in the event that the gauge glass is damaged? |

try cocks |

|

|

what is the simplest variation of sealing the perimeter of the butterfly disc in its closed postion |

use an elastomer-lined bore that is an interference fit on the disc |

|

|

this the connecting component between the valve actuator and the valve disc |

the valve stem |

|

|

what is the mechanism that causes the valve stem to move in a valve referred to? |

the operator |

|

|

what is the backseating feature on a valve stem |

a marking on the disc face that the valve is in the full open position |

|

|

what is put on a valve stem so the position of the valve can be viewed from a considerable distance |

brightly coloured plastic caps |

|

|

what is the inside screw rising stem used in the construction of |

small globe valves |

|

|

what is the major variation between stop check valves and regular globe valves |

there is no connection between the end of the valve stem and the disc on the check valve |

|

|

this valve stem is used with linear action pneumatic or hydraulic actuators on control valves |

sliding valve stems |

|

|

this valve stem is used with ball, plug and butterfly valves |

rotary valve stem |

|

|

what is recommended as part of the valve installation by the manufacturer |

the valve be run through a full open and close cycle after installation in the line |

|

|

how should the butterfly and ball valve stem be installed as per manufacturer recommendation |

in the horizontal position6

|

|

|

what is the general practice for mounting globe valves

|

the valve stem in the vertical position, with inlet flow pushing the valve up from the seat |

|

|

which direction are check valves installed

|

the flow arrow pointing in the direction of system flow

|

|

|

these check valves are used in low-pressure liquid and gas services |

folding disc check valves |

|

|

what is the similarity of operation of a diaphragm and pinch valve |

both depend on an external force to collapse and squeeze the outside of the walls of the flow passage together to cause a closure |

|

|

what is linear motion |

valves move in a straight line to start, stop or throttle flow |

|

|

what is rotary motor |

valves have closure members that move along an angular or circular path |

|

|

rotary motion valves that require only a 90deg turn from full open to full closed are classified as this |

1/4 turn valves |

|

|

What is the rough classification of small valves |

2" NPS or smaller |

|

|

what is galling

|

a tearing of the surface that occurs when two pieces of metal slide across each other under high contact stresses |