![]()

![]()

![]()

Use LEFT and RIGHT arrow keys to navigate between flashcards;

Use UP and DOWN arrow keys to flip the card;

H to show hint;

A reads text to speech;

71 Cards in this Set

- Front

- Back

|

Mesophile |

Organism that grows best in moderate temperatures 68-113F(body temp) |

|

|

Psychrotrophs |

Cold tolerant bacteria that grow at low temperature 59-68F but minimum 32F (refrigerator temp)ther |

|

|

Thermophile |

Organism that thrives at relatively high temperature between 106-125F |

|

|

Name the three terms of bacteria |

Mesophile Psychotrophs Thermophile |

|

|

Bacteria can be identified as either |

Gram positive or gram negative |

|

|

Gram positive |

Thick layer of peptidoglyen ( protein with sugar) which retains crystal violet dye |

|

|

Gram negative |

Thin layer of peptidoglycan that does not retain the violet dye( red/pink under microscope) |

|

|

Aerobic organism |

Can survive and grow in an oxygenated environment |

|

|

Anaerobic organism (anaerobes) |

Does not require oxygen for growth, facultative anaerobe ( uses oxygen available but also have anaerobic methods of energy production) Aerotolerant anaerobes Don’t use oxygen but are not harmed by it |

|

|

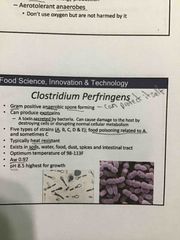

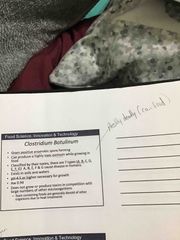

Clostridium perfringens |

Back (Definition) |

|

|

Clostridium perfringens |

Back (Definition) |

|

Front (Term) |

Back (Definition) |

|

|

Bacillus cereus |

Gram positive aerobic spore forming Can produce exotoxin while growing in food Found in soil, dust and water Growth temp of 40-120F pH 4.9 or higher Aw 0.27 ( spores survive long periods in dry foods, cereal grains |

|

|

Two types of Bacillus cereus toxins |

Emetic and diarrheagenic |

|

|

Emetic |

Vomiting Symptoms within 1-6 hours and last for 6-12 hours High dose necessary 10(5) - 10(8) Nausea, vomiting |

|

|

Diarrheagenic |

Symptoms within 8-16hrs and last for 6-12 hrs High dose necessary 10(5)- 10(9) Nausea, abdominal pain, watery stool |

|

|

Food bacillus cereus is commonly found in |

Rice, cereal dishes with corn, mashed potatoes, vegetables, minced meat |

|

|

How to control bacillus cereus |

Vegetative cells destroyed by heating to 212F or with sorbic acid benzoate, ethylenediaminetetraacetic (EDTA) Diarrheal toxin inactivated at 133F for 5 minutes Emetic toxin stable in stable in foods and not destroyed by cooking |

|

|

Listeria Monocytogenes |

Gram positive, non-spore forming Widely distributed in nature - found on decaying vegetation in soil animal feces sewage and water -may be expected to exist where lactic bacteria occur Foods: raw milk,soft cheese ,fresh and frozen meat, poultry, seafood Aw 0.90 or higher pH: 4.0- 8.0 |

|

|

Listeria Monocytogenes symptoms |

High dose required for infection Incubation 1 day duration 6hrs to 10days Fever, diarrhea, muscle aches, nausea, vomiting, fatigue, stillbirth |

|

|

How to control Listeria Monocytogenes |

Plant sanitation GMP control measures in HACCP plans Microbiological testing with QA hold Heat treatment |

|

|

Staphylococcus aureus |

Gram positive non-spore forming May produce toxins Common source of food contamination is with infected workers nasal carriers and open wounds, sores, boils, unpasteurized milk Can be expected to exist, at least at low numbers in any all foods of animal origin or handled directly by humans unless heat processed Aw 0.86 pH 6-7 Temperature 45-118F |

|

|

Staphylococcus aureus |

Can grow in presence of 7-10% NaCl Symptoms -develop within 4 hours last for 24-48 hrs -nausea, vomiting, abdominal cramps, diarrhea, sweating, headache Food- refrigerated after prepared, pork products those contaminated by infected workers non-heat treated eggs animal meats |

|

|

Salmonella spp |

Small gram negative non-spore forming Widely distributed in nature with humans and animals as primary reservoirs -intestinal tract primary habitat -can be found in polluted water Aw 0.93 pH 6.6-8.2 Temperature 41-115F( optimum 95-110) |

|

|

Salmonella spp symptoms |

Develop within 8-72 hrs lasts for 2-7 days Abdominal cramps, nausea, diarrhea, mild fever, vomiting, headache |

|

|

How control Salmonella spp |

Transmitted through fecal matter proper hygiene proper animal slaughter heat treatment |

|

|

Shigella spp |

Gram negative non spore forming Facultative anaerobe Contamination sources: water and soiled hands Typical food: cheese herb orange juice salad Aw 0.96 pH 4.8-9.3 Temperature 43-117 F |

|

|

Shigella spp symptons |

Develop within 12 hours to 4 days last 3-14 days Abdominal pain, diarrhea,fatigue,fever,mucus and occasional blood in feces Small amount of cells for dose requirement 10-100 |

|

|

How to control shigella spp |

Proper hygiene, good sanitation GNP’s, thermal processing, proper washing of salads, herbs, vegetables |

|

|

Coliforms |

Gram negative rods that ferment lactose Contamination sources water and fecal matter Typical foods of concern: ready to eat fresh vegetables meat products Low number of coliforms are permitted in foods as most non pathogenic |

|

|

Escherichia coli |

Gram negative non spore forming Toxin producing Facultative anaerobe Contamination sources: fecal matter, workers, contaminated water Some strains non pathogenic some strains are EC 0157:H7 Typical food of concern: ready to eat, ground meat, Apple juice, salad, raw milk Aw 0.95 pH 4-10 Temperature 44-121F |

|

|

Symptoms of coliforms |

Develop within 3-9 days last 3-7+ days Diarrhea, bloody stool, abdominal pain, kidney disease, vomiting, death |

|

|

How to control escherichia |

Proper hygiene, good sanitation gmp, thermal processing |

|

|

Vibrio parahaemolyticus |

Gram negative non spore forming Facultative anaerobe Contamination sources water Foods of concern seafood Aw 0.94 pH 4.8-11 Temperature 46-110F |

|

|

Vibrio parahaemolyticus symptoms |

Develop within 4-74 hrs last from 1-7 days Abdominal cramping, watery diarrhea, nausea, vomiting, fever High dose required |

|

|

How to control Vibrio parahaemolyticus |

Thermal processing, ensuring shellfish gathered from approved waters, avoiding cross contamination, good sanitation gmps |

|

|

Campylobacter jejuni |

Gram negative non spore forming Facultative anaerobe Contamination sources: animal intestinal tract, contaminated water Food of concern: raw poultry raw milk red meat mushroom salads shellfish Aw 0.98 pH 4.9-9.5 Temperature 86-113F |

|

|

Campylobacter jejuni symptoms |

Develop 1-10 days last 1-7 days Muscle pain, headache, fever, diarrhea, abdominal pain, nausea |

|

|

How to control Campylobacter jejuni |

Thermal processing, avoiding cross contamination, good sanitation gmp |

|

|

HACCP |

Hazard Analysis critical control point |

|

|

Define HACCP |

Comprehensive, systematic approach to applying appropriate science based methods and technology to plan, control and document safe production, handling and preparation of food |

|

|

What is the use of HACCP |

HACCP covers food safety issues and is applicable from farm to table - focused more on prevention of potential hazards rather inspection by outside agency - deals with unintentional types of hazards that may arise during production & processing |

|

|

History of HACCP |

Late 1950-1969 developed conjunction with pillsbury Android nasa ( native army laboratory - prevent foodborne illness in space program - testing over half products produced , cost prohibitive 1988- national advisory committee on microbiological criteria for foods ( NACMCF) was formed - current HACCP concepts developed -7 principles issued in 1989 report |

|

|

Regulatory HACCP |

December 18 1994- FDA issues the seafood HACCP regulation - all facilities that process seafood products for human consumption are under mandatory HACCP as of December 1997 July 25 1996- pathogen reduction HACCP final ruling passed in federal register - outlined the responsibility of plant in inspection personnel - major switch for burden of proof to meat processing establishment |

|

|

Intent of HACCP |

HACCP regulation was designed to: - reduce the numbers of pathogenic microorganisms on food products - reduce the incidence of foodborne illness - Provide a framework for meat and poultry inspection |

|

|

Prerequisite of HACCP |

Good Manufacturing practice ( GMPs) - general statement Standard Operating Procedure (SOPs) -specific how-to instructions Sanitation standard operating procedures ( SSOPs) -specific to sanitation |

|

|

Pre-HACCP |

Assemble a team of experts on the production process List and describe products to be produced ( product description Describe flow of production ( flow diagram) |

|

|

Describing the product HACCP |

Common name How is it to be used - ready to eat, heated prior to consumption or for further processing Type of package Length of shelf life Where will it be sold - wholesale, retail, institutional Labeling instructions- keep refrigerated How is the product distributed- product should be kept refrigerated Who is the consumer and how will the product be used by the consumer |

|

|

Flow diagram |

Clear outline of the steps involved in the manufacturing process Should cover all steps under the control of the plant It can also include steps in the food chain before and after processing |

|

|

Three types of hazards |

Biological Chemical Physical |

|

|

Biological hazards |

Microbiological pathogens |

|

|

Chemical hazard |

Cleaning residues Allergens |

|

|

Physical hazard |

Foreign material Bone, metal, plastic, glass |

|

|

7 principles of HACCP |

Hazard analysis Critical control point Critical limits Establish monitoring procedures Establish corrective action procedures Establish record keeping procedures Establish verification procedures |

|

|

Hazard analysis |

Most important principle List all potential hazards of ingredients, raw materials and process steps/ equipment Decide if identified risk needs to be addressed Completed analysis provides the basis for determining CCP’s in principle two Review ingredients used in the product Review the activities required at each step Review the equipment used and it’s characteristic Review the final product - handling, storage, distribution, intended use, product customers Team develops list of potential biological chemical or physical hazards |

|

|

Hazard evaluation |

Based on severity and likelihood of occurrence HACCP flowchart - position process components in the actual sequence they exist in plant: raw materials to packaging & storage - include details of critical process steps: temperature, pH, time - add hidden risk points such as consumer abuse, storage, transport |

|

|

Hazards |

Significant - low risk hazards usually addressed in GMP and or SSOP’s Likely to occur - prevention, elimination or reduction to acceptable level is essential to produce a safe product |

|

|

Determining risk for hazard analysis |

Estimate of likely occurrence of hazard Severity- magnitude and duration of illness- public health impact Occurrence- experience- epidemiological data - information in technical literature |

|

|

Categories of risk assessment |

Food intended for consumption by at risk population Products containing sensitive ingredients- a source of hazards: eggs No process step to eliminate hazard Recontamination potential before packing Potential for product abuse No terminal heat process - RTE that doesn’t require reheating |

|

|

Critical control point |

Step in the process where control of the three hazards types is necessary to: - prevent the hazard from entering the process - eliminate the identified risk from production Reduce to an acceptable level |

|

|

Control point vs CCP |

Control point - a point step or procedure a which biological physical or chemical factors can be controlled ; metal detection before grinding; decontamination after cooking Critical control point - point,step, or procedure at which control can be applied and a food safety hazard be prevented eliminated or reduced :metal detection after packaging; pasteurization; pG drop during fermentation |

|

|

Consideration for using ccp decision tree |

Used after the hazard analysis Used at steps where a hazard that must be addressed in HACCP plan has been identified Subsequent steps in process may be more effective in control More than one step may be involved in control More than one hazard may be controlled by a step |

|

|

How many CCP’s should a plan have? |

Depends on - food product produced -ingredients used - processing methods -prerequisites programs implemented Too many CCP’s may burden the HACCP system Too few CCP’s may result inadequate control of food safety hazards |

|

|

Establishing critical limits |

An identified value necessary to prevent eliminate or reduce an identified hazard to an acceptable level at a particular control point |

|

|

Critical limits |

For each ccp a critical limit is established to signify whether a ccp is in or out of control |

|

|

Exceeding critical limit indicates |

Existence of direct health hazard Direct health hazard could develop Product not produced under conditions assuring safety

Setting critical limits - should be based on research Published and reviewed research papers In plant studies |

|

|

Parameters for critical limits |

Time Temperature Water activity pH Salt concentration Weight Visual evaluation |

|

|

Regulated critical limits |

Some products already have established CCP in USDA regulations: -Time and temperature for ground beef -zero tolerance for fecal contamination If an agency has a regulation on a CCP it must be used |

|

|

Steps in establishing critical limits |

For each critical control point - determine if there is a regulatory cL or find one based on scientific evidence - if there’s no regulatory critical limit you may have to obtain assistance from outside HACCP experts -file letters or other documentation for critical limits you had to determine for validation |

|

|

Establish monitoring procedures |

A series of planned observation or activities that must be performed at an established time frame to ensure that the ccp is being properly controlled

Must be able to produce an accurate record of measurement or observation |

|

|

Purpose of monitoring critical limits |

Track systems operations - trends towards loss of control - action taken before limit exceeded Determines when there is a loss of control and corrective action needed Provides written documentation for use in verification of HACCP plan |