![]()

![]()

![]()

Use LEFT and RIGHT arrow keys to navigate between flashcards;

Use UP and DOWN arrow keys to flip the card;

H to show hint;

A reads text to speech;

19 Cards in this Set

- Front

- Back

- 3rd side (hint)

|

What is a pump? |

A mechanical device that pushes or move fluid or air from one place to another |

|

|

|

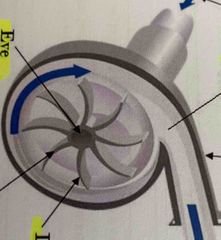

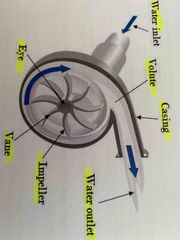

Centrifugal pump components? |

Back (Definition) |

|

|

|

What is an impeller? |

Circular disc is with curved vanes enclosed by second disc that imparts energy on water |

|

|

|

What’s the role of the volute? |

It slows water down and coverts from velocity energy to pressure energy, channels water |

|

|

|

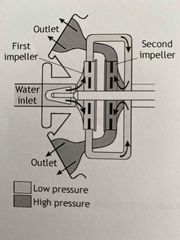

What does a Multi-stage series pump do and benefits? |

Uses a series of impellers to increase the pressure of water in the pump Operates in high flow and high pressure |

|

|

|

Pump and primers when drafting? |

Primers are used when obtaining water from a static/open water source Rotary vane primers Piston primers |

|

|

|

Pump lifts in metres? |

3m - rated pump 4.5m - approx 20% loss 6m - approx 40% loss 7.5m - approx 66% loss 10m - Max lift |

|

|

|

Powering the pump there are two types of redirection devices? |

Transfer case - the pump and the rear wheels can not be operated at the same time, it is not connected to the transmission Power Take-Off(PTO) - attached directly to the transmission and usually applied to side or top of gearbox. PTO can be engaged and the vehicle can still be driven |

|

|

|

Impeller cooling Pumper vs Heavy Pumper? |

Pumper - has an automatic impeller cooler however this is only short term and a second deliver valve should be open to avoid heating up (run a bleed) Heavy pumper - recirc valve allows for small flow of water to cool pump |

|

|

|

What is Cavitation and what are the causes? |

The formation of water vapour bubbles in a steam of water. It directly affects the pumps performance and suction lift Causes- clogged strainer, suction hose that is too long or too small, a lift which is too high, water that is warm, attempting to pump more water than the hydrant can supply or by using a small supply hose |

|

|

|

Close vs open circuit relay pumping? |

Open is when you can see the water closed is when you can’t see the water |

|

|

|

MKV Pumper specifications, uses and pump? |

Darley 1000 series Mid mounted single stage centrifugal pump with an additional second stage high pressure 3800LPM @ 1000 KPA and a lift of 3m H: 3.1m W: 2.5m L: 8.1m Weight: 12.8 operational tonnes 16 tonnes GVM Fuel: diesel 200L - offside Water capacity: 1300L Foam A: 25L Foam B: 300L Pump engine PTO Auxiliary Pump- allows operation of high pressure without the need to engage pump master Pumping rates high pressure: 1000kpa: 80LPM 2000kpa: 200LPM 3000kpa: 270LPM 3000kpa: 470LPM with two lines each at 235LPM Ideal pressure is 1000kpa for low pressure and 2000kpa for high pressure 4 delivery outlets and 4 inlets |

|

|

|

MKV pumper driveline for pumping? |

Engine, PTO, main pump and 2 stage |

|

|

|

MKV Pumper Monitor? |

Deck master - 3800LPM at 1000kpa Foam 3% is the same as the above Foam 6% - 2650LPM at 1000kpa Always reduce pressure down to 350kpa before engaging Monitor |

|

|

|

Ground monitor is called and flow rate? |

Blitz fire portable found Monitor All water and foam - 2000LPM at 1000KPA Elevation 10 to 50 degrees Horizontal 20 degrees Monitor should never exceed 1200kpa Must be manned at all times Tie off Ensure legs are fully extended |

|

|

|

MKV Pumper primer? |

Rotary vane primer pump Pull for 10 seconds to prime for 3m lift Do not exceed 90 seconds of priming |

|

|

|

MKV Pumper Tanker specifications, pump rate and capacity? |

Darley 1000 series single stage centrifugal pump with an additional second stage high pressure. 3800lpm @ 1000kpa with a 3m lift H: 3.3 W: 2.5 L: 8.6 Weight: 17.5 operational tonnes 28.5 tonnes GVM Water capacity: 3200L Monitor 3800lpm at 1000kpa PTO directly attached to transmission therefore truck needs to be placed into drive to activate Auxiliary can be activated in cabin due to the deluge capability |

|

|

|

Heavy pumper mills tui specifications, pump and capacity? |

Rear mounted Godiva prima World Series twin bronze plated multi stage pump driven by a split shift PTO. 4000lpm @ 1000kpa with a 3m lift Water capacity: 2000L H: 3.35m W: 3m L: 8.15m Weight: 13.2 tonnes operational 18.6 tonnes gvm B class foam: 200L Fuel: 200L diesel tank Pump driven by transmission and PTO, need to place in drive to activate pump Low pressure: 4000LPM at 1000KPA High pressure: 750LPM at 5500KPA Max flow capacity: 6200LPM Priming system: automatic Pressure relief valve: automatic Pump cooling: recirc valve used to cool as well as a small pressure valve fitted between high and low pressure pumps Water delivery: low pressure 450LPM at 1000kpa High pressure: 2000kpa ~ 200LPM Hose reals: 2x60m one each side |

|

|

|

Heavy Pumper Monitor and ground monitor? |

Roof monitor: TFT hurricane, 600 to 4700LPM flow rate Ground monitor: protek 700KPA flow setting of 950LPM |

|