![]()

![]()

![]()

Use LEFT and RIGHT arrow keys to navigate between flashcards;

Use UP and DOWN arrow keys to flip the card;

H to show hint;

A reads text to speech;

25 Cards in this Set

- Front

- Back

|

Pipe |

Constant outside diameter Necessary to move fluids with high static pressure |

|

|

Tube |

Constant inside diameter Necessary for moving Refrigerant at high pressure |

|

|

Steel pipe |

Use for water & ammonia |

|

|

Copper |

(Soft drawn and hard drawn) Always seamless . |

|

|

Single flare or double flare Flare fittings |

Double flare fitting are suitable for higher working pressure than single flare fitting. Double is suitable for very thin walled tubing such as type M |

|

|

Acetylene |

Water + calcium carbide + Silica lime in cylinder + acetone Acetone provide stabilizing affect. Burn at 2700 F Spontaneous combustion at atmospheric pressure 581 F |

|

|

Acetylene cylinder |

Always store upright, If stored sidewise allow 15 mins to allow internal chemical to stabilize Cylinder is of steel ANSI thread size 0.0885” internal diameter. 14 threads per inch Thread is left handed |

|

|

Acetylene |

92.2 % carbon 7.8 % hydrogen Highly explosive |

|

|

Regulator |

Reduce acetylene pressure from 250 psi to 15 psi Keep regulator set at 15 psi Both cylinder and regulator has left hand thread. Turn counterclockwise to tighten regulator regulator on cylinder |

|

|

Acetylene bottle valve |

Always open it 1/4 turn |

|

|

ACR copper |

Special cu for Refrigeration and air conditioning |

|

|

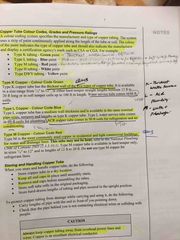

Type K Copper - Color code Green |

Thickest wall among all copper. Water service tube comes in 66 ft coils |

|

|

Type L - Color code Blue |

Medium thick wall ACR tube for ref and ac is type L ACR tube comes in 50 ft coils. |

|

|

Type M copper- Color code Red |

Mostly use for for water and drainage lines |

|

|

Soldering - solders |

95/5 and soft silver |

|

|

95/5 |

95% Tin & 5 % Antimony Melting point 450f & 232c

Liquid or paste flux Join cu to steel Cu to brass Cu to cu |

|

|

Soft silver solder |

Tin & silver 430 f & 221 c Liquid or paste flux Used cu to dissimilar metals like brass, steel and stainless |

|

|

Brazing - Rods |

Silver alloy wire Silver alloy Brazing rod 5 Silver alloy brazing rod 15 |

|

|

Silver alloy wire |

45% silver with cu,Zn, cd. No flux added 680-700 C Silver brazing flux (Borax) Joining ferrous and non ferrous that melts above 1500 F |

|

|

Silver alloy brazing rod 5 |

5% cu & 5% Ag with p as flux 870-890 c Cu to cu no flux Silver brazing flux for cu to brass Cu-cu Cu to brass |

|

|

Silver alloy brazing rod 15 |

15% cu 15 % Ag & P as flux 780-820 c Cu- cu no flux Silver brazing flux for cu to brass Cu to cu Cu to brass |

|

|

Type H copper tubing |

White paint |

|

|

Type DWV tubing |

Yellow paint |

|

|

Pipe colour code and grades |

Back (Definition) |

|

|

Pipe colour code and grades |

Back (Definition) |