![]()

![]()

![]()

Use LEFT and RIGHT arrow keys to navigate between flashcards;

Use UP and DOWN arrow keys to flip the card;

H to show hint;

A reads text to speech;

12 Cards in this Set

- Front

- Back

|

Whenever a wear surface can be economically reclaimed... |

Surface welding is used to return the equipment to its original thickness. |

|

|

Surface welding often employs a two-step procedure to reclaim worn parts |

1) a softer less expensive metal is deposited on the surface to return the part to its required thickness 2) a layer of hard surface material is applied over the first layer to promote durability and extend the parts service life |

|

Name this variation of a fillet weld |

chain intermittent fillet weld |

|

Name the fill it weld variation type |

Staggered intermittent |

|

Name the fillet weld variation type |

Intermittent fillet welds |

|

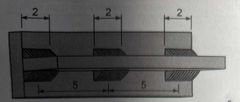

Where are square groove welds best applied? |

Sheet metal. Up to 1/8 thickness for single welded square groove And a maximum of 1/4 in thickness for double welded square groove |

|

The bevel groove is often used in which position? |

Horizontal, using the flat edge on one side to your advantage. Offered used where you have access to only one member of the joint. |

|

The v groove is the most widely used for materials between 3/8 inch thick to 1 in thick material. What are the benefits to using a double v groove? |

Reduces shrinkage and distortion |

|

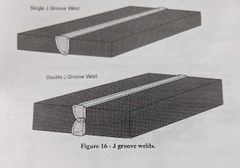

Which position is the J groove favored towards? What is the advantage of the j-groove compared to the bevel? |

The horizontal position Better access for welding which promotes good penetration and fusion to the bottom of the joint. |

|

|

What purposes do corner joints generally serve?? |

Tool boxes fuel tanks, trucker boxes, and similar items. |

|

|

What does the designation 1GR represent?? |

1 is flat welding position G is groove weldR is rotated or rolled weld R is rotated or rolled weld |

|

|

A variety of joint weld types may be on a single piece of equipment. What must you do?? |

Prepare and weld to join as specified so it performs to the required standard |