![]()

![]()

![]()

Use LEFT and RIGHT arrow keys to navigate between flashcards;

Use UP and DOWN arrow keys to flip the card;

H to show hint;

A reads text to speech;

136 Cards in this Set

- Front

- Back

|

What are the three types of lens materials used today? |

-glass

-CR-39 (standard ophthalmic plastic) -polycarbonate |

|

|

The three characteristics that must be considered when designing an ophthalmic lens are:

|

-thickness

-chromatic aberration -weight |

|

|

chromatic abberation

|

-typically a colored fringe around an image

-a type of distortion in which there is a failure of a lens to focus all colors to the same convergence point -occurs because lenses have a different refractive index for different wavelengths of light |

|

|

Abbe` number

|

-may reduce chromatic abberration

-describes the dispersive power of the lens material -"V-number" -high V values = low dispersion |

|

|

ANSI

|

-American National Standards Institute

-has established and published standards for the manufacturing of lenses for ophthalmic use ( www.opticampus.com/tools/ansi.php ) |

|

|

crown glass

|

-ophthalmic quality of glass most commonly used |

|

|

CR-39

|

-is a hard resin

-refractive index = 1.498; V number = 57.8; specific gravity = 1.32 -thicker than glass, produces the same chromatic aberration as glass, MUCH lighter than glass (about 50% lighter) -has a tendency to fog less -dye absorbed uniformly, directly into the lens -scratches easier than glass -more prone to warpage from tension on the lens by the eyewire |

|

|

What is the proper cleaning method for CR-39?

|

rinse with warm tap water, apply cleaning solution (if desired), pat dry with a soft lint-free cloth/tissue

|

|

|

polycarbonate plastic lens

|

-another form of plastic/ophthalmic grade of lexan

-refractive index = 1.586; V number = 30-32; specific gravity = 1.2 (10% thinner than crown glass/15 thinner than CR-39)-filters 99% of UV rays naturally -V number being low causes chromatic abberration -most impact resistant lens (good for children, athletes, and monocular patients) |

|

|

Trivex lens

|

-a newer lens material that offers superior optics, impact resistance, and is ultra lightweight

-refractive index = 1.53; V number = 43-45; specific gravity = 1.11 -strength of lens makes it excellent for drill-mount frames -can be tinted up to a #2 tint and can have anti-reflection and scratch resistant coatings |

|

|

high-index plastic lenses

|

-made of polyurethane

-refractive index = 1.58-1.74; V number = 32-57; specific gravity = 1.3-1.5 -the thinnest, most distortion-free lenses -less impact resistant than polycarbonate |

|

|

What must be considered when dispensing the thinnest lenses possible?

|

-frame size, aspheric design, and center thickness

-clinical rule of thumb = use high index material for myopes over -3.00D and +2.00D for hyperopes |

|

|

frame size

|

-the smaller the frame choice, the thinner the lens

-try to match distance between centers to patient's PD -try to select a frame that places the patient's eye slightly above the vertical center of the frame |

|

|

lens material

|

-thinnest materials are polycarbonate or high-index plastic

-when maximum impact protection is desired, recommend polycarbonate or Trivex |

|

|

aspheric design

|

-decreases in power toward the periphery creating a thinner lens

-effective for high plus powers (reduces bulge & magnification) |

|

|

center thickness

|

-order lenses as thin as possible

-polycarbonate can be made with a 1.0-1.5 center thickness |

|

|

What are the 2 categories of impact-resistant lenses?

|

-dress eyewear

-occupational protective lenses *MUST MEET ANSI STANDARDS* |

|

|

dress eyewear

|

-must have lenses that are impact resistant to withstand the impact of a 5/8" steel ball dropped from 50" (drop-ball testing)

-CR-39, polycarbonate, and high-index plastic are more impact resistant; are strong enough for random drop-ball testing -glass lenses must be treated to meet and pass drop-ball testing |

|

|

heat tempering

|

after a lens is cut and edged, it's placed in a vacuum and brought close to its melting point, then rapidly cooled so tension is created between the inner and outer molecular layers; this results in some lens surface distortion

|

|

|

chemical tempering

|

lenses are placed in a very hot chemical bath where an ion exchange takes place in the surface of the glass (left in bath for 15-17 hours)

|

|

|

occupational lenses

|

-"industrial safety lenses"

-new ANSI standard has two levels of performance 1.basic impact, 2.high impact -non-plano lenses must pass drop-ball test with 1" steel ball -must have MINIMUM thickness of 3mm -high plus MINIMUM thickness of 2.5mm -must be tested to high-velocity impact test (1/4" steel ball traveling 150 feet per second) |

|

|

single-vision lenses

|

have one optical center that will correct vision at a given distance

|

|

|

What are the 3 designs of single-vision lenses?

|

spherical, plano cylindrical, spherocylindrical

|

|

|

spherical lenses

|

-has the same power in all meridians

-corrects simple myopia or hyperopia |

|

|

planocylindrical lenses

|

-has no power in one meridian and 90 degrees away has the most power

-corrects astigmatism |

|

|

spherocylindrical lenses

|

-has a spherical component throughout the lens and it is the exclusive power in the axis

-cylindrical power varies in all meridians with the maximum cylinder being 90 degrees from the axis meridian -plus cylinder ground on the front of a lens -minus cylinder ground on the back of a lens -corrects myopia or hyperopia, and astigmatism |

|

|

multifocal lenses

|

a single lens with more than one point of focus

|

|

|

progressive addition multifocal lenses (PAL)

|

-has a distance RX in upper portion of the lens and progressively changes to the near RX in the lower portion

-in ALL progressives there is an area where the add power increases (may cause peripheral distortion) |

|

|

What are the 3 major designs of PAL lenses?

|

hard design, soft design, multidesign

|

|

|

hard design PALs

|

-area of add power is small, allowing a wide reading area and good DVA

-will produce peripheral distortion caused by unwanted cylinder power -good for hyperopes |

|

|

soft design PALs

|

-have a wider transition zone which spreads out the unwanted cylinder power

-has long intermediate corridor and softer optics -good for emerging presbyopes and those with adaption problems |

|

|

multidesign PALs

|

uses characteristics of soft design in the lower add powers, gradually creating a lens that is hard in design in the higher add powers

|

|

|

Wavefront technology (aberrometry)

|

-lenses that help eliminate some of the unwanted aberrations and provide a greater range of comfort (i.e. Physio & Physio 360 use digital surfacing of both the front and back lens surfaces)

|

|

|

fitting PALs

|

1) adjust the frame - height of progressive power, VD, pantoscopic angle, and bridge

2) measure height of the progressive power - from deepest part of the frame to the center of the pupil using a seg height gauge 3) measure monocular distance PD - use a corneal reflex pupillometer 4) verify the lenses 5) demonstrate the lenses |

|

|

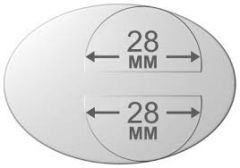

straight-top bifocals

|

-a.k.a. flat tops, D-segs

-available in one piece plastic and fused glass -widths available = 25, 28, 35, 40, & 45mm (28 & 35mm are most common) -optical center is closer to the segment line (less image jump) -height generally measured from the deepest part of the eyewire to the wearer's lower lash line |

|

|

round bifocals

|

-available in one-piece and fused types

-most commonly used diameter = 22mm -advantage = less visible -disadvantage = more image jump (due to lower placement of the segment optical center) -"Kryptok bifocal" = glass lens with a 22mm round fused segment of flint glass -height generally measured from the deepest part of the eyewire to the wearer's lower lash line |

|

|

full-width bifocals

|

-a.k.a. executive or Franklin bifocals

-glass or plastic; always made in one piece -advantage = wide field of near vision and almost no image jump (because the optical center of the segment is on the segment line) -disadvantage = lens thickness, curves and edge result in a less secure fit in frame eyewire -fitting height generally positioned at the lower lash line |

|

|

trifocals

|

-most are manufactured with an intermediate power that is 50% of the near power (any other % is special order)

-available in straight top or executive -fitting: top line of segment is generally positioned at the lower pupil edge when the wearer is looking straight ahead in normal room illumination |

|

|

occupational segments

|

-most common = double segment bifocal (has a segment at the top and the usual segment on the bottom of the lens

-available in straight top, round, and full width; 13-15mm separation between upper and lower segments -quadrifocals = straight top trifocal for bottom segment, straight top bifocals at the top segment; available in 22, 25, & 28mm; intermediate height can be 6, 7, 8, or 10 mm high |

|

|

aspheric lens designs

|

-designed using a series of curves on the front surface rather than the one simple spherical curve (making the surface more elliptical);thinner and less distorted

-used for manufacturing of lenticular lenses designed for aphakes and PALs |

|

|

aphakic lenses

|

-used for patients who have not been fitted with an IOL

-multiple-drop aspheric lens = designed so there is a drop in power that begins several mm from the center of the lens and continues to the periphery; cosmetically more appealing -can be single vision or multifocal (multifocal should be 1 mm below pupil and in a frame no larger than 50mm) |

|

|

myodisc lenses

|

-is a high minus lens with a lenticular design

-front surface is plano, lenticular bowl is on back and is 30mm (this bowl consists of a deep concave depression) -available in single vision, fused and one piece bifocal designs |

|

|

balance lenses

|

ordered for a monocular patient to balance the eyewear cosmetically

|

|

|

fresnel membrane press-on lenses

|

-is a thing plastic sheet, about 1mm thick

-is placed on the ocular surface of an existing lens -often used in vision therapy and as postsurgical temporary lenses for aphakes, as well as permanent treatment for a hemianopsia(partial field loss) |

|

|

lens base curve

|

-considered as the front surface curve

-BC of a spherocylinder lens is the flattest front surface curve (most often the only front surface curve) -BC of a MF lens is the curve of the distance portion on the segment side -the cylinder is always ground on the opposite side of the segment |

|

|

scratch-resistant coatings

|

-are a layer of resin that protects the lens from many surface scratches

-best scratch-resistant coatings are factory applied (lenses are molded and cured with the hard-coated surface) |

|

|

anti-reflective coatings

|

-offers improvements in vision and cosmetic appeal; increases the light transmission of a clear lens from 92% to 99%

-most commonly applied by coating companies or by the lens manufacturer -consists of many microscopically thin layers of various metallic oxides that are applied in a vacuum under highly controlled conditions |

|

|

anti-particulate technology

|

-new version of the multilayer anti-reflective coating offering more of a smudge resistant surface

-achieved by adding a layer of silicone to the lens surface -cleans with hot water and a soft lint-free cloth -Crizal & Zeiss are the most common |

|

|

UV coatings

|

-designed to filter out UV light up to 400 nm (even in a clear lens)

-UV coatings are added to plastic lenses in a tinting unit and to glass by a coating company -polycarbonate = naturally UV absorbing |

|

|

mirror coatings

|

-reflect some of the light striking the lens, increasing the density of the lens |

|

|

sports coatings |

-designed to improve contrast sensitivity and reduce glare -snow screen (skiers) designed to function in white-on-white light -seascreen (water sports) designed to function best in blue-green light -landscreen (land based) designed to reduce visible light |

|

|

How are the sports coatings applied? |

-through a series of coatings that begin with a yellow-brown coating applied to the concave (front) side; a double-gradient filter is applied to the convex (back) side to reduce glare from above and below; third layer is a reflection-reducing coating applied to the concave side -these coatings eliminate 100% UV light, 80% IR light, and 90% of distracting blue light |

|

|

What are the 4 general categories of colored lenses? |

-glass lenses with absorptive tints -glass lenses coated with color -plastic lenses colored in a dye bath -photochromic glass or plastic lenses that change color when exposed to sunlight |

|

|

How are lens tints graded? |

by the percentage of light transmission; #1 being the lightest (greatest amount of transmission), and #3 being the darkest (least amount of transmission |

|

|

#1 lens tint |

65%-80% light transmission |

|

|

#2 lens tint |

45%-60% light transmission |

|

|

#3 lens tint |

15%-40% light transmission |

|

|

a clear lens has a light transmission of: |

92% |

|

|

Absorptive glass tints are produced by: |

by adding color to the glass during the manufacturing process, while the glass is in it's liquid state: not available in grandient style tints |

|

|

cobalt oxides tint glass: |

blue |

|

|

manganese oxides tint glass: |

violet, gold, red |

|

|

uranium oxides tint glass: |

yellow |

|

|

didymium oxides tint glass: |

pink |

|

|

cerium oxides tint glass: |

brown |

|

|

iron oxides tint glass: |

green |

|

|

nickel, iron, cobalt oxides tint glass: |

gray |

|

|

pink tint |

-used for partial absorption of UV light -frequently used for photophobic patients -transmits visible spectrum evenly, thereby preserving the natural color values

|

|

|

gray tint |

-reduces the intensity of all transmitted wavelengths evenly so colors are seen in normal relationship -primarily used when absorption of UV and IR light is needed -excellent for sun lenses |

|

|

green tint |

-provide absorption of UV and partial absorption of IR rays -primarily for industrial use -alters color values slightly |

|

|

brown tint |

-absorbs UV and some IR rays -reduces blue haze and fog -greatly alters color values -"blue blockers" |

|

|

yellow tint |

-used on dark foggy days tobrighten the background -absorbs UV light but has a high transmission of IR rays -good for shooting & downhill skiing on cloudy days -theoretically, they cut through the haze to render distance objects more visible |

|

|

glass color coatings |

-done by applying a metallic oxide to the lens front surface in a vacuum -are uniform in density and any lens design can be coaeted (also makes gradient tinting available) -have slight metallic reflection and tend to attract dust, lint, and grease |

|

|

plastic lens dye-bath tinting |

-tinted by dipping in a liquid dye bath ~> dye is heated in a double boiler type system; dye penetrates evenly for uniform density -allows for gradient tinting and multiple colors on one lens -recommeded to be re-dyed yearly -can be changed, darkened, lightened, or removed |

|

|

photochromic lens tints |

-change color when exposed to radiant energy-primarily, but not exclusively, the near UV rays -available in glass, plastic (CR-39), polycarbonate, and high-index lens materials |

|

|

What are the most popular glass photochromic lenses? |

-PhotoGrey Extra and PhotoBrown Extra -darkens in 60 seconds, and lightens over 75% of their range in 10 minutes |

|

|

What is the main darkening force of photochromic lenses? |

UV light - but will also react slightly to visible light (i.e. bright rooms and flash photography) |

|

|

What is the break-in period for photochromic lenses? |

about 2 weeks |

|

|

photochromic lenses |

-absorb UV light but not IR light -not uniform in density, available in full range of RX powers and lens designs -ordering a single lens replacement could result in an uneven tint |

|

|

darkening forces of photochromic glass |

-UV energy -more recent exposure -colder -thicker |

|

|

fading forces of photochromic glass |

-visible red/IR light energy -less recent exposure -warmer -thinner -chemical tempering |

|

|

wavelengths of light (darkening force) |

-the nature of wavelengths of light affects transmission -UV light=main darkening force |

|

|

recent exposure (darkening force) |

photochromic lenses have an exposure memory; more recent exposure in lenses will darken quicker than those with less recent exposure |

|

|

temperature (darkening vs. fading force) |

the colder the temperature, the darker the lens will get |

|

|

thickness (darkening vs. fading force) |

the thicker the lens, the darker it will get |

|

|

tempering (darkening vs. fading force) |

chemical tempering is recommended for optical performance of all photochromic lenses; causes a slight increase in the darkened transmission |

|

|

plastic photochromic lens tints |

-introduced in march 1989 by Rodenstock as the colormatic plastic photochromatic lens -it's light tan indoors with about 80% light transmission, changes to medium gray with UV light with about 50% light transmission -designed for comfort not sun -Photocolors (another plastic photochromic lens) has changeable tints in aquamarine, amethyst, and emerald and has light transmission indoors to about 86% and outdoors to about 45% |

|

|

transitions |

-became available in single-vision and straight-top 28, and PALs in 1991 -updated to transitions plus in 1992; are less sensitive to temperature and are a great general use for patients with plastic lenses who want changeable tint (at 95 degrees will darken to about 48%) -gray when exposed to UV light -updates are Next Generation and Transitions V |

|

|

properties of transition lenses |

-lightweight plastic -scratch resistance -100% UV absorption -medium to dark gray tint outdoors; light blush color indoors -automatic adjustment to light -no darkening for flash photography -fully lighten indoors and darken quickly when exposed to UV light |

|

|

polarized sun lenses |

-designed to eliminate glare reflected from flat surfaces -some are made of films of polarizing material: mitrocellulose packed with ultramicroscopic crystals f herapathite, with optic axles parallel to each other -laminated between clear or lightly tinted lenses -others made with polarized material molded into it -available in glass and plastic in gray, green, and brown |

|

|

What type of glass is used in the manufacture of ophthalmic lenses? |

crown glass |

|

|

Standard ophthalmic plastic lenses are made from a material called ___________________. |

CR-39 |

|

|

Plastic lenses transmit _____ light _____ glass. |

slightly more; than |

|

|

The index of refraction for a polycarbonate lens is _______. |

1.586 |

|

|

Polycarbonate material filters out ___% of UV rays. |

99% |

|

|

Which lens material can produce the thinnest, most distortion-free lenses? |

high-index plastic |

|

|

Whenattempting to dispense the thinnest lens possible, which type of design will reduce the bulge and magnification of plus lenses? |

aspheric design |

|

|

During chemical tempering of glass lenses for impact resistance, the lenses are left in a hot chemical bath for _______ hours. |

15-17 |

|

|

what is compromised when the surface of a glass lens is scratched? |

impact resistance |

|

|

What is the minimum thickness allowed in the average industrial safety lens? |

3.0 mm |

|

|

A __________ lens is used to correct a combination of myopia or hyperopia with astigmatism. |

spherocylindrical |

|

|

The hard design PAL lenses are recommended for ___________ patients. |

hyperopic |

|

|

The Abbe value of Trivex is: |

43-45 |

|

|

For a PAL lens to work properly, the minimum fitting height should ___________? |

be known before taking the measurement, as each manufacturer may have different fitting heights |

|

|

What was the first bifocal style? |

executive |

|

|

The ____________________ is the most commonly prescribed occupational lens for patients who perform overhead work. |

double segment bifocal |

|

|

The base curve of a spherocylinder lens is the ________________ surface curve. |

flattest front |

|

|

Antireflective coating increases the light transmission of a clear lens from ___% to ___%. |

92%, 98% |

|

|

Polycarbonate lenses don't need ________________ coating, since their surfaces already have this property. |

UV |

|

|

According to which of the following are lens tints graded? |

amount of light transmission |

|

|

_______________ absorptive glass tinted lenses reduce the intensity of all transmitted wavelengths evenly, allowing colors to be seen naturally. |

gray |

|

|

Which absorptive glass tinted lenses are used as "blue blockers" |

brown |

|

|

Which type of light does a photochromic lens absorb? |

UV |

|

|

Which type of light does a photochromic lens NOT absorb? |

IR |

|

|

The polarized lens is designed to eliminate glare reflected from _______ surfaces. |

flat |

|

|

What three characteristics must be considered in the design of an ophthalmic lens? |

thickness, chromatic aberration, and weight |

|

|

A manufacturing standard established by the ANSI for glass lenses is: |

the lens must be heat or chemically tempered |

|

|

List five advantages of CR-39 over glass lenses: |

lighter, don't fog as easily, tinting is more uniform and can be manipulated, less glare and internal reflections, improves visual performance |

|

|

List three advantages of glass lenses over CR-39 lenses: |

more scratch resistant, thinner because of the index of refraction, don't warp as easily |

|

|

Why is polycarbonate a good choice of lens material for children and monocular patients? |

polycarbonate is more impact-resistant than crown glass and CR-39 |

|

|

What is the material used to make high-index plastic lenses? |

polyurethane |

|

|

What factors must be considered in order to dispense the thinnest lens possible? |

frame size, lens material, aspheric design, and center thickness |

|

|

What is the ANSI standard for drop-ball testing in dress eyewear? |

must withstand the impact of a 5/8" steel ball dropped from 50" |

|

|

What is the ANSI standard for drop-ball testing for industrial safety lenses? |

must withstand the impact of a 1" steel ball from 50" |

|

|

What other standard, in addition to drop-ball testing, applies to industrial safety lenses? |

safety lenses must have a minimum thickness of 3.0mm |

|

|

Is the following statement true or false? "Polycarbonate, high-index plastic, and CR-39 lenses don't have to be routinely tested in the lab by the drop-ball test." |

True |

|

|

Name two methods of treating glass lenses for impact resistance. |

heat temper and chemical temper |

|

|

What type of PD is measured when fitting progressive addition lenses? |

monocular |

|

|

When dispensing a pair of PALs, the manufacturer's markings: |

will help the dispenser make the final frame adjustments. |

|

|

What is an identifying factor of an executive/Franklin bifocal? |

a large ridge that runs across the entire width of the lens |

|

|

What is the most likely intermediate power if the near power is +3.00? |

+1.50 |

|

|

A nurse states she has to tilt her head back to read the small numbers on the IV bag with her current bifocals. This is causing her neck to hurt. Which lens designs whould be discussed with her? |

double-segment bifocals |

|

|

If which circumstances should the CPO specify a base curbe when ordering a lens from an optical lab? |

when lens powers are very different for each eye, high-diopter power corrections, and prescriptions for patients who have a sensitivity to base curve changes |

|

|

List two benefits of antireflective coating. |

increase the amount of light entering the eye; they eliminate ghost images and light reflections in the lens |

|

|

What tint grade would be used for a patient who is extremely light sensitive? |

#3 |

|

|

Which tint is commonly known as "blue blocker"? |

brown |

|

|

Is the following statement true or false? "Photochromic lenses are only available in glass." |

false |