![]()

![]()

![]()

Use LEFT and RIGHT arrow keys to navigate between flashcards;

Use UP and DOWN arrow keys to flip the card;

H to show hint;

A reads text to speech;

198 Cards in this Set

- Front

- Back

|

Engineering Mechanics |

Branch of Engineering that deals with the analysis of external effects of forces on rigid bodies |

|

|

Kinematics |

Dynamics: do not consider mass; calculates the trajectory |

|

|

Kinetics |

Dynamics: consider mass; calculates the motion & the causes of that motion |

|

|

Tension / Tensile Force |

an external force that creates a pulling / stretching action on a material |

|

|

Compression / Compressive Force |

an external force that creates a push/ squeezing action on a material |

|

|

Resultant Force |

a single force whose effect is representative of the cumulative effects of each force in the system |

|

|

kg•m/(s^2) |

Newton = |

|

|

bay length |

distance between trusses |

|

|

span |

distance between supports |

|

|

Uniformly Varying Load |

Load applied on the entire span/ at a specified portion of a structure which varies from zero or any minimum amount of load to any maximum value |

|

|

Free Body Diagram (FBD) |

An isolation of a force or a system of forces that acts at specific parts of a structure or machine element in consideration |

|

|

Space Diagram |

A sketch showing the physical conditions of the problem |

|

|

Free-Body Diagram |

A sketch showing only the forces on the selected particle |

|

|

Free-Body Diagram |

an isolation of a force or system of forces that acts at specific parts of the structure/ machine element in consideration |

|

|

Equilibrium |

a state in which the resultant force system that acts on a body vanishes. It means that both the resultant force & the resultant couple are zero. |

|

|

Couple |

two parallel forces equal in magnitude but oppositely directed. It produces a rotation /moment |

|

|

Friction |

the contact resistance developed by a body upon another body due to the action of a force that moves/ tends to move the two bodies past each other |

|

|

Moment of Inertia (the mass moment of inertia, angular mass/rotational inertia of a rigid body) |

a quantity that determines the torque needed for a desired angular acceleration about a rotational axis |

|

|

Strength of Materials |

branch of Engineering that deals with the internal effects of forces on the body |

|

|

Strength of Materials |

a branch of applied mechanics that deals with the behavior of solid bodies subjected to various types of loading |

|

|

stress |

unit strength of element |

|

|

strain |

unit deformation of a material when loaded |

|

|

stress |

internally distributed forces that tends to change or resist the effect of forces upon the body |

|

|

Extensometer |

instrument used to measure a minute deformation; strain gauge |

|

|

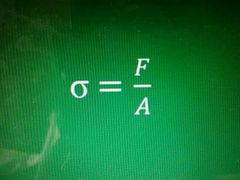

stress |

|

|

|

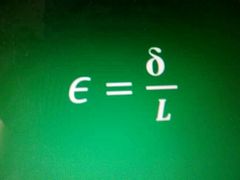

strain |

|

|

|

Hooke's Law |

"stress is proportional to strain" |

|

|

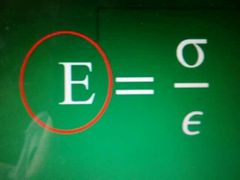

Young's Modulus / Modulus of Elasticity |

|

|

|

Sir Robert Hooke (the Hooke's Law) |

Who first noticed the linear relation between the elongation and the axial force in 1678 |

|

|

Modulus of elasticity or young's modulus |

The constant proportionality k is called _____. This is equal to the slope of the stress-strain diagram from O to P |

|

|

Proportional Limit |

the greatest stress that a material is capable of withstanding without deformation / deviation & obeys Hooke's law |

|

|

Elastic limit |

the limit beyond which the material will no longer go back to it original shape when the load is removed, or the maximum stress that e developed such that there is no permanent or residual deformation when load is entirely removed. |

|

|

Yield point |

the stress in a material at which an increase in strain occurs without an increase in stress |

|

|

Ultimate stress |

a point wherein a material is about to rupture |

|

|

Yield point |

The point at which the material will have an appreciable elongation/ yielding without any increase in load. |

|

|

Ultimate strength |

the maximum ordinate in the stress-strain diagram |

|

|

Rupture strength/ the breaking strength |

the strength of the material at rupture |

|

|

Elastic Range |

the region in stress-strain diagram from 0 to P |

|

|

Plastic Range |

the region in stress-strain diagram from P to R |

|

|

Modulus of Resilience |

the work done on a unit volume of material as the force is gradually increased from O to P, in N•m/m3 . May be calculated as the area under the stress-strain curve from the origin O up to the elastic limit E |

|

|

Resilience of the material |

the material's ability to absorb energy without creating a permanent distortion |

|

|

Modulus of toughness |

the work done on a unit volume of the material as the force is gradually increased from O to R , in N•in/m3. May be calculated as the area under the entire stress-strain curve (from O to R) |

|

|

toughness of a material |

material's ability to absorb energy without causing it to break |

|

|

Young's modulus/ Modulus of Elasticity |

A property of the material that tells us how easily it can stretch & deform & is defined as the ratio of tensile stress to tensile strain |

|

|

Young's modulus/ Modulus of Elasticity |

the ratio of load per unit area (stress ) to the elastic deformation per unit length (strain). |

|

|

Modulus of Rigidity/ Shear Modulus |

the ratio of shear stress to the displacement per unit sample length (shear strain); the coefficient of elasticity for a shearing force; denoted by G defined as the ratio of shear stress the shear strain |

|

|

Plasticity |

the property of a material, by virtue of which, a permanent deformation (without fracture ) takes place whenever it is subjected to action of external forces / load -inelastic strain in a material |

|

|

toughness |

property of a material that does not break under a sudden shock ability of material to withstand shock loading ; ability to absorb energy before rupturing |

|

|

Resilience |

The capacity of a material to absorb energy elastically; the maximum energy which can be stored in a material up to elastic limit ; the capacity of material to bear shocks & vibrations. |

|

|

Tensile strength |

the ability of a material to stretch without breaking/ snapping |

|

|

Yield strength |

stress a material can withstand without permanent deformation |

|

|

Impact strength |

the reaction of stationary object to a collusion w/ a moving body; The energy required to fracture a material under an impact force |

|

|

Ductility |

a measure of the deformation at fracture; defined by percent elongation/ percent reduction in area; property that enables the material to deform under tensile load |

|

|

Hardness |

property of a material that enables it to resist plastic deformation , usually by penetration |

|

|

Ductile Fracture |

a gradual process of nucleation, growth & coalescence of micro-cracks in the structure + local stress concentration; extensive plastic deformation ; fracture surface is rough, fibrous, & dull (Characteristic 'cup & cone' shape) |

|

|

Fatigue strength |

at which a material does not fail under repeated loading |

|

|

fatigue |

A progressive fracture / failure under repeated loading |

|

|

fatigue |

when materials fails at stresses below the yield point ; a structural damage that occurs when a material is subjected to cyclic loading |

|

|

Creep |

continuous deformation of concrete with time under loads; time-dependent deformation which occurs at elevated temperature ; plastic flow may occur; ability to flow like fluid |

|

|

Wear Resistance |

capacity of a material to resist abrasion |

|

|

Rupture strength |

strength in which a material breaks/ cracks ; the ability to resist this failure |

|

|

Malleability |

the quality of something that can be shaped into something else, without breaking |

|

|

Malleability |

the ability to deform under compressive stress / load |

|

|

gold |

the most malleable metal |

|

|

Modulus of Elasticity; Young's Modulus |

the ratio between the unit stress& the unit deformation caused by stress |

|

|

Shear Modulus of Elasticity / modulus of Rigidity (G) / Modulus of torsion |

the ratio between shearing stress the shearing stain |

|

|

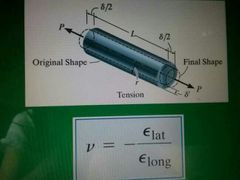

Poisson's Ratio |

the ratio of the transverse contraction strain to longitudinal extension strain in the direction of stretching force |

|

|

Poisson's Ratio |

|

|

|

Strain Rate Effect |

the behavior an increased rate of load application can cause in normally ductile material |

|

|

Temperature Effect |

the brittle behavior a low temperature can cause in a normally ductile material |

|

|

Stress |

When a material is loaded with a force it produces ________ |

|

|

Strain |

The response of the system to an applied stress |

|

|

Strain |

Engineering ______ is defined as the amount of deformation in the direction of the applied force divided by the initial length of the material. |

|

|

1 Pascal (Pa) or 1 N/m2 pound-force per square inch or psi |

Stress is expressed in ___or__. In Imperial units, stress is measured in __or___. |

|

|

Compressive stress |

a stress that tends to cause a body to become shorter along the direction of applied force. |

|

|

Axial stress |

a stress that tends to change the length of a material |

|

|

Tensile stress |

axial stress that tends to cause a body to become longer along the direction of applied force |

|

|

Strain |

Change in length divided by the initial length |

|

|

strain |

term used to measure the deformation/ extension of a body that is subjected to a force / set of forces |

|

|

Shearing stress |

a stress produced when one body slides the other |

|

|

Bearing/ Normal stress |

a stress produced when one body is in contact normal to the other |

|

|

Bearing/ Normal stress |

contact pressure between separate bodies |

|

|

Compressive stress |

the internal stress caused by a compressive force |

|

|

Torsional Stress |

a stress produced when the force applied tends to twist the body |

|

|

Torsional Stress |

specific type of Shear stress in which one end of a part is secured while the other end is twisted |

|

|

Torsion |

the twisting of an object due to an applied torque |

|

|

Circumferential stress |

a stress produced at the thin-walled cylinders |

|

|

Bending/ Flexural stress |

tends to cause bending of materials like beams. |

|

|

Flexural/ Bending stress |

Force per unit area of a material that is subjected to flexural loading |

|

|

Flexural strength |

the ability of the material to withstand bending forces applied perpendicular to its longitudinal axis, the stresses induced due to the flexural load are a combination of compressive & tensile stresses |

|

|

Thermal stress |

the physical & Physiological reactions of the human body to temperatures that fall outside of the human normal comfort zone |

|

|

Bond stress |

the force of adhesion per unit area of contact between two bonded surfaces, such as between concrete & a steel reinforcing bar |

|

|

allowable stress |

the maximum stress that a material can carry without failure |

|

|

Ultimate Stress |

maximum stress a material can handle before fracture |

|

|

Fatigue stress |

the stress level below which an infinite number of loading cycles can be applied without failure |

|

|

Fatigue limit or fatigue strength |

the endurance limit |

|

|

Rupture stress |

the sudden & complete failure of a material under stress |

|

|

point of contraflexure |

inflection point |

|

|

Compression |

Act of shortening / state of pushing together |

|

|

Tension |

act of stretching/state of pulling apart Effect: elongation example: Boom chord & web members of trusses |

|

|

Transverse |

act of bending a structure Effect: deflection Example: beams |

|

|

Torsion / moment |

act of twisting/ bending effect: shear deformation / deflection |

|

|

dead load |

weight of materials & any permanent loads imposed on it. |

|

|

Live load |

movable loads applied on the materials |

|

|

Wind load |

force on structure arising from the impact of wind on it; depends on the location (exposure) & typhoon signal |

|

|

Seismic load |

force on structure arising from the impact of earthquake on it. It depends on the epicenter & magnitude of earthquake |

|

|

Impact load |

abrupt application of load . It is an additional load based on the weight applied on the material (NSCP) |

|

|

Hydrostatic pressure |

force on structure exerted by water |

|

|

Soil pressure |

force on structure exerted by soil |

|

|

three-second gust speed at 10m above the ground in Exposure C |

Basic wind speed (NSCP) |

|

|

Punching Shear |

arises when a concentrated load is applied to a small area of a slab or, most commonly, the reaction of a column against a slab |

|

|

Angle of repose |

The steepest angle at which a sloping surface formed of a particular loose material is stable. It varies locally according to the mechanics & strength |

|

|

Angle of Friction |

the angle between the total reaction & the normal force when limiting fiction is acting |

|

|

Concurrent forces |

Forces whose lines of action meet at a common point |

|

|

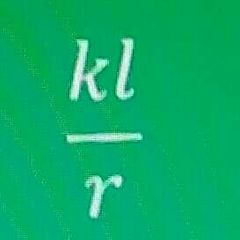

slenderness ratio |

ratio of effective length & radius of gyration |

|

|

Radius of gyration |

the measure of the propensity of a column to buckle |

|

|

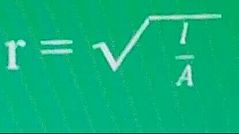

radius of gyration |

where I = moment of inertia |

|

|

Slenderness Ratio |

|

|

|

Inflection point |

a point in the elastic diagram in which the curvature reverses as it changes from concave to convex or vise versa |

|

|

Inflection point(changes its curvature)/ point of contraflexure (bending moment changes in sign) |

A point within the beam where the moment is zero |

|

|

Structure |

an assemblage of framing members designed to support gravity loads & resists lateral forces |

|

|

Slab |

structural element made of concrete, that is used to create flat horizontal surfaces such as floors, roof decks, & ceilings; generally several inches thick & supported by beams , columns, walls, or by the ground |

|

|

One way slab |

a slab which is supported by beams on two opposite sides to carry the load along one direction |

|

|

one way slab |

A slab supported by beam on all sides, where the ratio of larger span to the shorter span is greater than 2 , or if the short direction to long direction is less than 0.5 |

|

|

t = l/ 20 (where l= shortside,& t should be greater than or equal to 100 mm) |

One-way Slab thickness when slab is simply supported |

|

|

t = l/ 24 (where l= shortside,& t should be greater than or equal to 100 mm) |

One-way Slab thickness when one end is continuous |

|

|

t = l/ 28 (where l= shortside,& t should be greater than or equal to 100 mm) |

One-way Slab thickness when both ends is continuous |

|

|

t = l/ 10 (where l= shortside,& t should be greater than or equal to 100 mm) |

One-way Slab thickness when slab is cantilevered |

|

|

two-way slab |

a slab supported by beams on all the four sides & the loads are carried by the supports along both directions.

the ratio of larger span to shorter span is less than or equal to 2 or short to long ratio is equal to or greater than 0.5

Main reinforcement is provided in both directions |

|

|

125 mm |

Two- way slabs without drop panels shall not have a thickness that is less than _____ mm |

|

|

100mm |

Two- way slabs with drop panels shall not have a thickness that is less than _____ mm |

|

|

75 mm |

Minimum cover when concrete is cast against & permanently exposed to earth |

|

|

A) 50 mm B) 40 mm |

Minimum cover when non-prestressed concrete is exposed to earth/ weather

If 20-58 mm diameter bar: ______(a) If 16mm diameter bar, MW 200 or MD 200 wire & smaller: ____(b) |

|

|

Minimum cover for slabs, walls, joists when non-prestressed concrete is not exposed to weather/ in contact with the ground

For 42-58mm diameter bars: _____mm For 36mm diameter bars & smaller : _____mm

|

A) 40 mm B) 20 mm |

|

|

40 mm |

Minimum cover for beams & columns when non-prestressed concrete is not exposed to weather/ in contact with the ground For primary reinforcement, ties, stirrups, spirals: _____mm |

|

|

A) 20 mm B) 12 mm |

Minimum cover for shells & folded plate members when non-prestressed concrete is not exposed to weather/ in contact with the ground For 20 mm diameter bar & larger: _____mm For 16 mm diameter bar, MW 200 or MD 200 wire & smaller : _____mm |

|

|

True |

True/ False: One-way bending may occur in slabs supported on four sides if L/S> 2 |

|

|

l / 360 |

Deflection limitation for floors not supporting or attached to non-structural elements likely to be damaged by large deflections |

|

|

l /480 |

Deflection limitation for roofs /floors supporting/ attached to non-structural elements likely to be damaged by large deflections |

|

|

l/ 240 |

Deflection limitation for roofs /floors supporting/ attached to non-structural elements not likely to be damaged by large deflections |

|

|

Batten Plate |

Plate rigidly connected to two parallel components of a built -up column/ beam designed to transmit shear between the components |

|

|

l/ 180 |

Deflection limitation for flat roofs not supporting/ attached to non-structural elements likely to be damaged by large deflections |

|

|

Ties |

Loops resisting buckling failure |

|

|

stirrups |

Loops resisting shear failure |

|

|

stirrups |

required to resist the vertical & diagonal tensions in the beam at the same time hold the bars in place |

|

|

150 mm |

Minimum Depth of Footing above bottom reinforcement for footings on soil |

|

|

300 mm |

Minimum Depth of Footing above bottom reinforcement for footings on piles |

|

|

200 mm |

Minimum Footing Depth of wall footing |

|

|

Pile |

basically a long cylinder of a strong material such as concrete that is pushed into the ground to act as a steady support for structures built on top of it |

|

|

Floating Foundation |

Footing used when deep deposits of compressible, cohesive soil are present, & piles are impractical |

|

|

Floating Foundation |

For this type of footing, the building's substructure is a combination mat & caisson to create a rigid box; the weight of the earth displaced by foundation is equal to total weight of structure, thereby minimizing settlement from consolidation |

|

|

Pile Foundations |

foundation used when there is a layer of weak soil at the surface which cannot support the weight of the building, so the loads of the building have to bypass this layer & be transferred to the layer of stronger soil / rock that is below the weak layer |

|

|

Pile foundation (capable of taking higher loads than spread footings ) |

foundation used when a building has very heavy, concentrated loads, such as in a high rise structure , bridge, or water tank |

|

|

Pile Foundations |

foundations used extensively for the support of buildings, bridges, & other structures to safely transfer structural loads to the around |

|

|

pile driver |

Precast driven piles are first cast at ground level & then hammered/driven into the ground using a ________; this is a machine that holds the pile perfectly vertical, & then hammers it into the ground blow by blow. Each blow is struck by lifting a heavy weight & dropping it on the top of the pile-. |

|

|

steel cap |

the pile is temporarily covered w/ a ____ to prevent it from disintegrating |

|

|

Pile driver |

acts as crane, & lifts pile from a horizontal position on the ground & rotates it into the correct vertical position, & then hammers the pile down into the ground |

|

|

micropiling / helical piling |

piling used in sensitive locations such as those near an operational hospital/ science lab,and some residential areas,& areas where vibrations could cause structural damage to older buildings that are close by. |

|

|

micropiles |

high capacity, small diameter (5"to 12") drilled & grouted jn-place piles designed with steel reinforcement to primary resist structural loading; ideal for Underpinning| emergency repairs |

|

|

micropiles / minipiles |

Methodology: small piles are constructed by digging a hole a little larger than the pile diameter & the full length of the pile using an apparatus like a soil boring machine . Then a precast concrete pile is lowered/ pushed into the hole , & a concrete grout is poured into the gap between the pile & the earth |

|

|

Helical piles |

steel tubes that have spiral blades attached to them. These can be drilled into the ground, meaning that the pile acts as a giant drill bit, & is rotated & pushed into the ground from above, much like a screw drills into wood. Once the steel pile is driven into the ground, a pile cap is poured on top of the pile to prepare it for the construction above |

|

|

Pile Cap |

structural member placed on, & usually fastened to. the top of a pile/ a group of pile & used to transmit loads into the pile/ group of piles. In the case of a group, to connect them into a bent |

|

|

Retaining Wall |

provided when there is a need to support an excavated area or a lower area of at least 1 or 1.2 m or more from an elevated part of the soil; often used to resist the lateral pressure caused by the soil |

|

|

overturning failure |

the retaining wall simply fails in bending |

|

|

Sliding |

Retaining wall failure: often had non-cohesive soils. the walls move outward with a passive failure of soil in front of foundation & active failure of soil behind the wall . Often a key is required beneath the foundation to prevent this type of failure. |

|

|

Bearing Check |

has be performed due to the failure of the soil under the toe of the foundation & a forward rotation of wall |

|

|

overstress |

(on any part of the retaining wall ) caused by either bending/shear . |

|

|

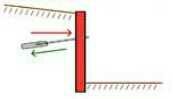

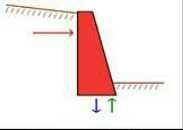

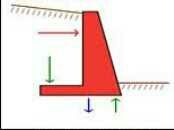

Anchored Wall |

|

|

|

Piling wall |

|

|

|

Gravity wall |

|

|

|

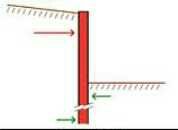

Cantilever Wall |

|

|

|

Purlins |

rectangular/ other shape members placed on top of the truss to directly support the roofing materials |

|

|

Roof battens |

Provide a breathable space allowing any consideration to be eliminated; increase the structural performance of roof truss systems; enable roofing materials to be secured firmly to the roof ; assist with correct alignment of roofing sheets |

|

|

Brittleness |

the ability of a material to crack / break without appreciable deformation when forces are applied |

|

|

Elasticity |

the ability of a material to return to its original shape & size when loads are released |

|

|

Creep |

the ability of material particles to flow like a fluid due to repeated loadings associated with high temperature |

|

|

Flexural strength |

the maximum bending stress that can be applied to that material before it yields |

|

|

Shear Stress |

force / stress tending to cause deformation of a material by a slippage along a plane / planes parallel to the imposed stress |

|

|

Circumferential / hoop stress |

a normal stress in the tangential (azimuth) direction |

|

|

Building Frame System |

An essentially complete space frame that provide support for gravity loads |

|

|

Bearing wall system |

structural system without a complete vertical load-carrying space frame |

|

|

Boundary element |

an element at edges of openings or at perimeters of shear walls or diaphragms |

|

|

Braced Frame |

an essentially vertical truss system of the concentric or eccentric type that is provided to resist lateral forces |

|

|

Component |

a part/ element of an architectural, electrical , mechanical , or structural system. |

|

|

Fatigue |

the weakening of a material caused by cyclic loading that results in progressive & localized structural damage & the growth of cracks |

|

|

distribution/ shrinkage bars/ temperature reinforcement |

the bars along long direction; provided near surfaces of concrete exposed to daily temperature changes |

|

|

Concrete |

an artificial stone derived from a mixture of properly proportioned amount of hydraulic cement, fine aggregates, coarse aggregates & water, with or without admixtures |

|

|

Batching |

the process of measuring concrete mix ingredients by either mass or volume and introducing them into the mixer. To produce concrete of uniform quality , the ingredients must be measured accurately for each batch |

|

|

Compaction of Concrete |

the process adopted for expelling the entrapped out from the concrete. Study found that 1 % air in the concrete reduces the strength by approx. 6%. If air is not expelled, it results to honeycomb |

|

|

Rodding |

done continuously over the completed area to effectively pack the concrete & drive away entrapped air using a 2m long rod with 16mm dia. The thickness of layers is 15-20cm |

|

|

Tamping |

adopting in compacting roof/ floor/ road pavements where the thickness of concrete is comparatively less & surface to be finished smooth & level. A wooden beam of cross section 10cm X 10cm is used. |

|

|

Curing |

the process in which the concrete is protected from loss of moisture & kept within a reasonable temperature range. The result of this process is increased strength & decreased permeability. It is also a key player in mitigating cracks in the concrete , which severely impacts durability, |

|

|

Slump test |

To determine the workability of concrete |

|

|

Gradation |

the particle size distribution of aggregates |

|

|

sieve analysis method |

Test for grading of aggregates is carried out using the _____ |

|

|

Segregation |

when large aggregate sink to the bottom of the mix during placement & vibration. |

|

|

Cohesiveness |

the ability of plastic concrete to hold its form |

|

|

admixture |

material other than water, aggregate or hydraulic cement used as an ingredient of concrete & added to concrete before & during its mixing to modify its properties |