![]()

![]()

![]()

Use LEFT and RIGHT arrow keys to navigate between flashcards;

Use UP and DOWN arrow keys to flip the card;

H to show hint;

A reads text to speech;

29 Cards in this Set

- Front

- Back

|

Why is it important to have a sharp chain? |

A dull chain produces sawdust that gets sucked into the air filter, cutting down the airflow to the power head and reducing power. It also does not allow the saw to cut smoothly and puts unnecessary strain on the power head. The sawyer is forced to press the chain saw into the cut, increasing stress on the power head (which could damage it). Also it makes the sawyer work harder and increases the risk of kickback. |

|

|

Why are the air and fuel filters important? |

They prevent dirt and other contaminants from entering the carburetor. |

|

|

Most guide bar problems develop in the bar rails and are caused by: |

Incorrect chain tension Lack of lubrication Improper cutting technique Normal wear |

|

|

What should you check on the spark plug? |

Check for fouling - the tip of the plug should be beige, not black. The plug should be dry. Ensure the plug is gapped if the saw is not running correctly. |

|

|

How do you purge a saw? |

Drain fuel from fuel tank. Run engine at idle speed until it stops. Choke and start again. Run saw while chokes to remove all fuel from the fuel line. Turn fuel filler hole face down, with fuel tank open, for five minutes. This will purge saw of fumes. |

|

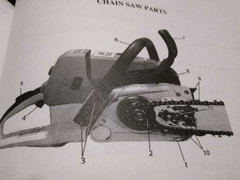

Identify the parts of a saw. |

|

|

|

How do you troubleshoot a flooded engine? |

Remove spark plug. Dry and check gap. With switch and choke off, pull starter several times to purge excess fuel from cylinder. Reinstall spark plug and attempt to start with choke off. |

|

|

What are the four types of binds? |

Top bind - the tension area is on the bottom of the log. The compression area is on the top. Bottom bind - the tension area is on the top of the log. The compression area is on the bottom. Side bind - pressure is exerted sideways on the log. End bind - weight compresses the log's entire cross section. |

|

|

How can you determine bind while cutting? |

Position yourself so you can detect a slight opening or closing of the kerf. If the kerf starts to open, there is a bottom bind. If the kerf starts to close, there is a top bind. |

|

|

Should the final cut be made through the compression area or tension area? |

The final cut, or release cut, will be made through the tension area. Because the offside has been cut, the sawyer only has to use enough bar to finish cutting the remaining wood. This allows the sawyer to stand back, away from danger. |

|

|

How do you cut a top bind? |

Cut the offside first, then partial cut on the compression side (top) finishing from the bottom, cutting up. |

|

|

How do you cut a bottom bind? |

Cut the offside first, then make a partial cut on the compression side (bottom). Finish with the release cut on the top. |

|

|

How do you cut blowdown (uprooted trees)? |

If possible, start limbing and bucking the blown down tree from the top and work your way toward the stump or root wad. |

|

|

What are five areas to analyze when considering a felling job? |

Issues with tree characteristics Problems with soundness or defects Defects in the base of the tree Issues with surrounding terrain Immediate work area |

|

|

What are issues to analyze with tree characteristics? |

Species Live or dead Sound or soft Widow-makers or hangups Diameter and height Frozen wood Heavy branches or uneven weight distribution Direction of lean(s) Degree of lean (slight or great) Head lean or side lean Stand health |

|

|

What are issues to analyze regarding problems with soundness or defects? |

Deformities, such as those caused by damage from weather, lightning, or fire Spike top Nesting or feeding holes Cat face Splits and frost cracks Bark and trunk soundness Twin or devil top or schoolmarm Deformities, such as those caused by mistletoe Rusty (discolored) knots Punky (swollen or sunken) knots Unstable root system or root protrusions Wounds or scars Split trunk Human-made hazards |

|

|

What are some issues to analyze regarding defects in the base of the tree? |

Thud (hollow) sound when struck Insect activity Conks and mushrooms Feeding holes Rot or cankers Bark soundness Shelf or "bracket" fungi Resin flow on bark A swollen base, indicating potential for hollow hole in hardwoods |

|

|

What are issues to analyze with surrounding terrain? |

Steepness Stumps Irregularities in the ground Loose logs Draws and ridges Ground debris that can fly or kick up at the sawyer Rocks |

|

|

What are issues to analyze regarding the immediate work area (things to look for)? |

People, roads, or vehicles Reserve trees (signed to mark administrative boundaries and location monuments) Power lines or fences Underground utility lines Structures Hangups or widow-makers Openings to fell trees Other trees that may be affected Snags Fire-weakened trees Other trees that may have to be felled first Hazards such as trees, rocks, brush, low-hanging limbs Footing Wind speed |

|

|

What should you listen for when sounding a tree with an axe? |

A sound tree will produce a "solid" sound. A soft tree will produce a "soft" sound or "thunk." |

|

|

What is "hinge wood"? |

A hinge is the uncut wood between the undercut and the back cut. It controls the direction and fall of the tree, unless the wood breaks (snaps). |

|

|

What two cuts does the undercut consist of? |

A gunning cut (also called "horizontal cut") and a matching cut (also called "sloping cut"). |

|

|

How do you use the gunning sights? |

Choose a target parallel to the desired lay of the tree and use the gunning sights (marks) on the saw to accurately aim the direction of the fall. This target is not the desired lay, it is parallel to the lay and the same distance away from the desired lay as the gunning sights are away from the bark. These sights are only accurate if you position yourself so that you can look directly down the length of a gunning sight, similar to aiming a rifle. A specific target should be used and memorized because you may use it again later in your back cut. |

|

|

Why is it recommended to use two wedges while felling? |

Using two side-by-side wedges in the back of the tree is recommended for a number of reasons. It distributes lifting load and support across a wider area, it facilitates easier wedging by having the ability to alternate hits, and it leaves one wedge in the tree if the other gets knocked out. |

|

|

How deep should the matching cut and gunning cut be? |

The two cuts combine at a depth 1/4 to 1/3 of the tree's diameter. |

|

|

Where should the backcut be located? |

The backcut is horizontal, above the gunning cut to allow for stump shot. The gunning and back cut should allow for hinge wood that is the thickness of about 10 percent of the tree's diameter. |

|

|

Briefly describe the backcut technique. |

Stand at the side of the tree with the power head adjacent to the undercut; the power head will be in front of the hinge with the bar behind the hinge. Hold the bar level, towards the back of the tree, parallel with the gunning cut but above it to allow for stump shot. Cut in on your onside only until the bottom of the bar reaches the back of the holding wood. Now, set your dogs in the side of the tree, and pivot the saw around to the offside. |

|

|

What do the choke symbols represent? |

(---) = choke is on (I) = choke is off The symbol represents the butterfly valve in the carburetor. When it's straight up, the butterfly valve is not restricting the air flow, therefore it is not choking. |

|

|

How does the choke work? |

The choke position increases the richness of the air and fuel mixture the carburetor sprays into the cylinder. With the master control lever in the choke position, the flow of fuel into the engine increases and the flow of air decreases. |