![]()

![]()

![]()

Use LEFT and RIGHT arrow keys to navigate between flashcards;

Use UP and DOWN arrow keys to flip the card;

H to show hint;

A reads text to speech;

21 Cards in this Set

- Front

- Back

- 3rd side (hint)

|

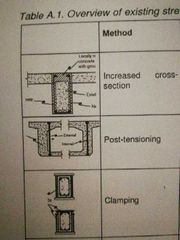

Concrete bridges |

Increased cross section (Inc moment of inertia) Post tensioning (reduces tensile strength & stresses) Clamping (adds stirrups externally) Stitching (overbridging cracks) |

|

|

|

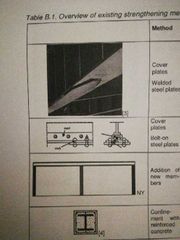

Metallic structures |

Cover plates( welded or bolted); welded to flanges or web; bolted to flanges Addition of new members (ensure carrying capacity) Confinement with reinforced concrete (jack up structure- most applicable to columns) |

|

|

|

Masonry arch |

Concrete saddle (replace existing fill) Prefabricated liners (structural lining installed beneath arch) Retro- reinforcement (Installation of additional structural reinforcement to the arch to increase structural capacity) |

|

|

|

Fracture mechanics |

|

|

|

|

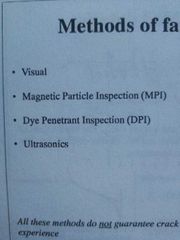

Methods of fatigue inspection |

|

|

|

|

Dpi |

Liquid applied to the surface which is drawn to the surface through a white powder. |

|

|

|

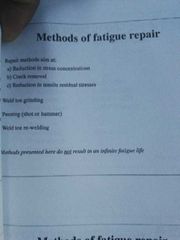

Methods for fatigue repair |

|

|

|

|

Higher the discount value |

The lesser is the present value of the future cost |

|

|

|

Fatigue in welded details |

Pre existing flaw(microscopic cracks) that can expand Stress conc expected at position of the locally changing geometry High residual stress |

|

|

|

Value you get from the hand out is |

Delta note- fatigue limit |

|

|

|

Frp |

High performance fibre contained in a resin matrix |

|

|

|

Types |

Carbon (CFRP) Aramid (AFRP) Glass (GFRP) |

|

|

|

5 different types of resin |

Phenolics- good fire resistance Polyesters- good general props/odour issues Poly- urethanes-good abrasion prop/poor temp performance Vinyl-esters- good fatigue/odour problems E-poxies- best resistance/ expensive |

|

|

|

Issues with frp |

No codes Relatively new No idea how to examine in the future |

|

|

|

Fibres |

Aramid- toughest Glass - economical Carbon- stiffest |

|

|

|

Why are frps used |

Light/soft/stiff/ durable Aesthetic Good in fire Retrospective strengthening Replacement of components |

|

|

|

AIP DOC |

Drafted by designer and reviewed by TAA (TECHNICAL APPROVAL AUTHORITY) |

|

|

|

AIP KEY COMPONENTS |

Location Structure Loads Analysis Geotech Checks Sig of authority and designer's Technical approval schedule |

|

|

|

Bridge scour analysis |

1. Field inspection 2. Hydraulic analysis 3. Hydrologic analysis 4. Sediment transport 5. Scour analysis 6. Risk estimation |

|

|

|

Scour risk management |

1. Anticipation 2. Assessment 3. Prevention measures 4. Preparation for emergency situation 5. Response 6. Recovery |

|

|

|

Scour risk assessment |

1. Data collection 2. Initial assessment (qualitative data) 3. Detailed assessment (quantitative data) 4. Long term management |

|