![]()

![]()

![]()

Use LEFT and RIGHT arrow keys to navigate between flashcards;

Use UP and DOWN arrow keys to flip the card;

H to show hint;

A reads text to speech;

14 Cards in this Set

- Front

- Back

|

Important Mechanical Properties |

▪ Strength ▪ Hardness ▪ Ductility ▪ Stiffness |

|

|

If a load is static or changes relatively slowly with time and is applied uniformly over a cross section or surface of a member, the mechanical behavior may be ascertained by |

Stress-Strain Test |

|

|

Three principal ways in which a load may be applied: |

▪ Tension ▪ Compression ▪ Shear |

|

|

can be used to ascertain several mechanical properties of materials that are important in design. |

The tension test |

|

|

is designed to elongate the specimen at a constant rate, and to continuously and simultaneously measure the instantaneous applied load (with a load cell) and the resulting elongations (using an extensometer). |

The tensile testing machine |

|

|

is used in ductility computations |

Gauge length |

|

|

Standard value of gauge length |

is 50 mm (2.0 in.) |

|

Front (Term) |

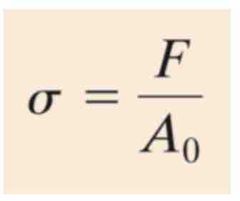

Engineering Stress |

|

Front (Term) |

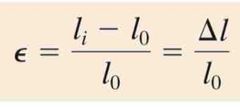

Engineering strain |

|

|

is conducted in a manner similar to the tensile test, except that the force is compressive and the specimen contracts along the direction of the stress. |

compression test |

|

|

is a variation of pure shear, wherein a structural member is twisted |

Torsion |

|

|

produce a rotational motion about the longitudinal axis of one end of the member relative to the other end. |

torsional forces |

|

|

is a function of the applied torque T |

Shear stress |

|

|

is related to the angle of twist |

Shear strain |