![]()

![]()

![]()

Use LEFT and RIGHT arrow keys to navigate between flashcards;

Use UP and DOWN arrow keys to flip the card;

H to show hint;

A reads text to speech;

12 Cards in this Set

- Front

- Back

|

Calculate the Modulus of Elasticity

|

E= change in stress/change in strain

|

|

|

Calculate the Percent Elongation

|

% elongation = (final length-initial length) / initial length

|

|

|

Calculate the Percent Reduction in Area

|

% Reduction in Area = (initial area-final area) / initial area

|

|

|

Calculate Poisson’s Ratio

|

Calculate Poisson’s Ratio

|

|

|

Calculate Resilience

|

Resil.

= 1/2 * (stress at elastic limit)^2 * (strain at elastic limit) = ((stress at elastic limit)^2) / (2*mod of elas) |

|

|

Calculate Resilience

Using Poisson’s Ratio and the Modulus of Elasticity, calculate the Shear Modulus of Elasticity. |

Calculate Resilience

Using Poisson’s Ratio and the Modulus of Elasticity, calculate the Shear Modulus of Elasticity. Shear Modulus = G = E / (2(1+γ); gamma = Poisson’s Ratio |

|

|

What does a high percent elongation indicate?

|

The material is more ductile and therefore formable.

|

|

|

State the differences between the stress-strain diagram created using the data in this excel sheet and a true stress-strain diagram. Using a true stress-strain diagram can provide us with what further information about the material.

|

The engineering stress-strain diagram created is not a measure of true stress and true strain. To get true values you need to measure the instantaneous gage lengths and diameters as the test proceeds using an extensometer. Once we have the true-stress and true strain we can determine the strain-hardening coefficient (n) which indicates how much a material will work harden when subjected to plastic deformation. This is important in many shaping and molding processes.

|

|

|

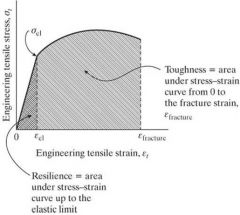

What is resilience, how does this differ from toughness?

|

Resilience is a measure of the ability of a material to absorb elastic energy

Toughness is the ability of the material to absorb all energy before fracture |

|

|

On a stress-strain graph, which area indicates resilience and which indicates toughness?

|

|

|

|

What materials is creep important in? What materials is creep not so important in?

|

Creep is very important in materials with low melting points such as polymers.

Creep is usually not important in metals with operating conditions under 800 F. |

|

What can be said about graphs a-d?

|

(a) Has significant work-hardening which is evident from it’s continued ability to withstand increased stress until fracture.

(b) exhibits very little work hardening but the ductility allows it to continue to elongate. (c) Is extremely brittle with no ability to work harden (d) Ductile plastics undergo a reorganization and “orientation strengthening” at the atomic level before fracture |