![]()

![]()

![]()

Use LEFT and RIGHT arrow keys to navigate between flashcards;

Use UP and DOWN arrow keys to flip the card;

H to show hint;

A reads text to speech;

32 Cards in this Set

- Front

- Back

|

Thermoplastics |

A polymer that softens when heated or reheated and gardens when cooled. |

|

|

Thermosetting |

A polymer that once cured by chemical reaction will not soften when reheated. |

|

|

What are the four kinds of polymer structures? |

Linear, branched, crosslinked, network |

|

|

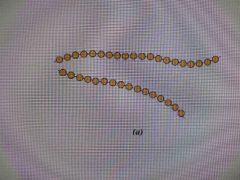

Linear Polymer |

A polymer produced from bifunctional monomers consisting of repeated units joined end to end in a chain. |

|

|

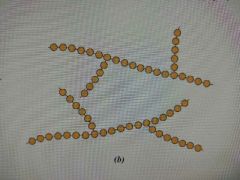

Branched Polymer |

A polymer having a molecular structure of secondary chains extended from the primary chains |

|

|

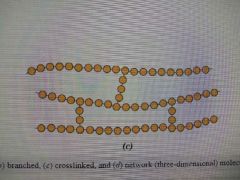

Crosslinked Polymer |

A polymer in which adjacent linear molecular chains are joined together |

|

|

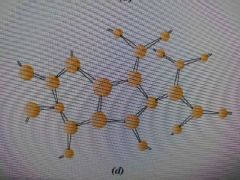

Network Polymer |

A polymer with multifunctional monomers having three or more bonds to for a 3D molecule |

|

|

Three types of stereoisomerism |

Isotactic, Syndiotactic, atactic |

|

|

Isotactic Configuration |

Polymer chain in which all side groups are positioned on the same side of the chain molecule |

|

|

Syndiotactic Configuration |

Polymer chain configuration where side groups alternate position. |

|

|

Atactic Configuration |

A polymer chain configuration where the side groups are randomly positioned |

|

|

Viscoelasticity |

A type of deformation exhibiting the mechanical characteristics of viscous flow and elastic deformation. The deformation is NOT instantaneous |

|

|

What effect does porosity have on ceramics? |

The higher the porosity volume fraction the weaker the ceramic becomes. |

|

|

Fatigue Limit |

The maximum stress amplitude level below which the material can endure essentially and infinite number of cycles. |

|

|

Composite |

A structural material that consists of two or more materials combined at the macroscopic level and are not soluble to one another. |

|

|

Name the types of composites |

Partial reinforced, fiber reinforced, structural, metal matrix, ceramic matrix, and polymer matrix. |

|

|

Metal Matrix Composite |

A composite where the matrix phase is metal and the reinforced phase are fibers, whiskers, or particles. High cost Used in aircraft and rocket engines |

|

|

Ceramic Matrix Composite |

A composite where both the matrix and reinforced phase are ceramics Used as diskbrakes and to reinforce ceramics. |

|

|

Polymer Matrix Composite |

A composite where the matrix is a polymer resin and fibers are dispersed particles High specific strength Corossive resistant Makes fiverglass or kevlar |

|

|

Corrosion |

Deterioration of properties due to a reaction with the environment |

|

|

Name the types of corrosion |

Uniform Attack Stress Corrosion Erosion Corrosion Pitting Crevice Galvanic Intergranular Selective Leaching |

|

|

Uniform Attack Corrosion |

Oxidation and reduction occurs uniformally over the surface (rust) |

|

|

Stress Corrosion |

When stress and corrosion work together at a crack tip |

|

|

Erosion Corrosion |

Breakdown of participating later by erosion (pipe elbows) |

|

|

Pitting Corrosion |

Downward propagation of small pits or holes |

|

|

Crevice Corrosion |

Corrosion between two pieces of the same metal |

|

|

Galvanic Corrosion |

Dissimilar metals are joined together and the more anodic one corrodes |

|

|

Intergranular Corrosion |

Corrosion along grain boundaries |

|

|

Selective Leaching |

Preferred corrosion of one element |

|

|

List factors of corrosion |

Electrolyte Electron Path Cathode Anode |

|

|

List ways to combat corrosion |

Proper naterial selection Coating Cathodic protection Inhibitiors Proper Design |

|

|

What makes metals good conductors? |

They have a high number of free electrons and allow for easy electron flow |