![]()

![]()

![]()

Use LEFT and RIGHT arrow keys to navigate between flashcards;

Use UP and DOWN arrow keys to flip the card;

H to show hint;

A reads text to speech;

27 Cards in this Set

- Front

- Back

|

Type of system that has condensate returning against the steam flow. And uses large pipe sizes to account for the counter flow of the steam ? |

One pipe counter flow system (1/4" per foot rise in direction of steam flow) |

|

|

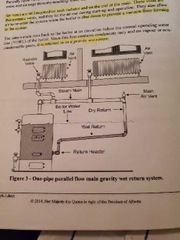

Type of one-pipe low pressure steam system using a separate pipe for condensate. This return main runs back to the boiler below the normal operation line. (***wet***) |

1-pipe parallel flow main wet return system |

|

|

One pipe parallel wet return systems require 1" of rise for every (25,30,15)ft of pipe of the main. Grades of 1/2"per (1ft,10ft) still required on the branches of the HMU |

Main piping 1" per 20ft Branches to HMU 1/2" per 1ft |

|

|

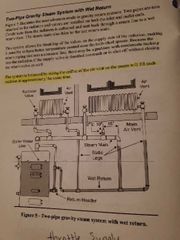

Type of 2-pipe system that allows for throttling on the supply side for temperature control in individual spaces. condensate return can back up into the HMU if not throttled properly. |

2-pipe gravity steam system with wet return |

|

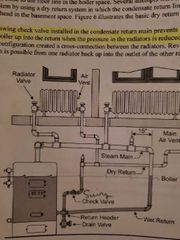

What is this type of steam system called? What type of valve is used to prevent backflow from the boiler ? |

2-pipe gravity steam system with dry return . |

|

|

What is the 1 major disadvantage with the 2-pipe gravity steam low pressure dry return system? |

Reverse flow of steam is possible through EMUs |

|

|

Wet return low pressure steam systems carry condensate in the return piping while Dry return low pressure steam return piping Carrys _________ & _____________ |

Condensate and gases) |

|

|

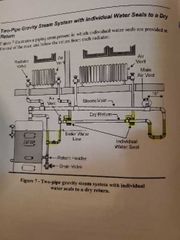

Type of 2 pipe system with a "trap like" piping arrangement called a water seal installed at the end of the main and at each HMU return pipe with seal below grade of a dry main return? |

2-pipe gravity steam system with individual water seal dry retun. |

|

|

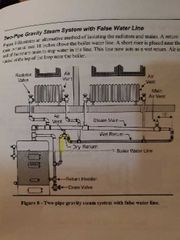

Alernative method of (*water seals*) isolating HMU and main with return main having to run at least ____ above boiler water line. Small loop installed near end of main to trap water in the return line acting as a wet return. |

2-pipe gravity steam system with false water line (return main running 18" above boiler water line) |

|

|

Steam traps were introduced into steam systems to prevent _______ ___________ of the steam and condensate spaces |

Cross connection |

|

|

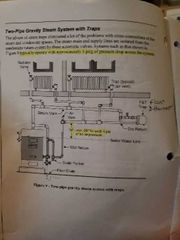

More advanced 2 -pipe steam system which uses a automatic valve acting as a trap to isolate steam main and supply lines ? |

2pipe gravity steam system w/ traps |

|

|

2 pipe steam systems w/ traps normally operate with approximately __ psig of pressure drop across the system . |

1 psig |

|

|

Vapour steam systems have 2 designs which are boiler _____ trap systems and direct ________ trap systems. |

Boiler return trap systems Direct return trap systems |

|

|

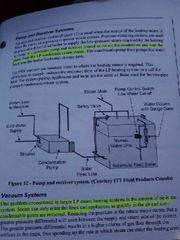

In a pumped condensate return system, the condensate line is a (wet/dry) return. |

Dry |

|

|

What purpose does a float control serve in a pumped condensate system?

|

Float control in receiver tank, when determined height in tank is reached condensate water is pumped through the return piping and back into the boiler. |

|

|

Steam can enter lines and HTUs as quickly as the ________ is removed |

Air |

|

|

Vacuum steam systems are a modified version of a pump and receiver system. Installed on a (closed/open) and is used to draw both ______ and _______ from the receiver tank |

Air & condensate |

|

|

Vaccum system pumps controlled by a vaccum switch to maintain average of ____" HG gauge in receiver tank. Float control valve installed on pump _________ line controls the flow of condensate from the (upper/lower) tank to the boiler. boiler. |

5 1/2" Hg gauge in receiver tank Float control installed on pump discharge. Upper tank to the boiler |

|

Upfeed system (left/right) Downfeed system (left/right) |

Upfeed=right Downfeed=left |

|

|

Steam systems are chosen when a large volume of _____ transfer energy is required to meet demands at a quick response time at high ________. |

Heat Speed |

|

|

Low pressure steam can be sub-catagorized by the method used to __________ ________________ back to the boiler |

Return condensate |

|

|

Steam heating systems typically categorized by ? |

Pressure |

|

|

If condensate and steam are flowing in the same direction, main should be graded __" in ___' or _____ in _______

|

1/2" inch in 12' Or 1 in 20 |

|

|

Only one pipe feeding from the main to EMU is called a ______ pipe system |

One |

|

|

Two-pipe gravity return systems with traps can operate with about ____psig pressure drop across system |

1 psig |

|

|

Pump on a condensate return is operated by a _____ control in the _______ tank |

Float control in recieving tank |

|

|

Makeup waterfeeders ________ designed to feed water as fast as steam is produced |

Are not |