![]()

![]()

![]()

Use LEFT and RIGHT arrow keys to navigate between flashcards;

Use UP and DOWN arrow keys to flip the card;

H to show hint;

A reads text to speech;

34 Cards in this Set

- Front

- Back

|

What are the five basic joint types? |

-Butt

-corner -tee -edge -lap (BCTEL) 120102e pg 2 |

|

|

What are the four weld types?

|

-surfacing

-plug or slot -fillet -groove 120102e pg 3 |

|

|

What is surface welding?

|

when a bead or beads are used in place a layer of weld metal over a surface

120102e pg 3 |

|

|

What is surface welding used for?

|

-Reclaim worn surfaces

-Place a layer of cladding 120102e pg 120102e pg 3 |

|

|

What are the two steps for surface welding?

|

1.Layer of softer less expensive weld metal returns metal to original thickness

2.Layer of hard surface material is applied to promote durability and extend part’s service life 120102e pg 3 |

|

|

What joint are plug or slot welds commonly used with?

|

lap joints

120102e pg 4 |

|

|

What joints are fillet welds found on?

|

lap, Tee and corner joints

120102e pg 4 |

|

|

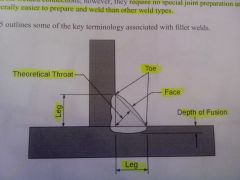

What is the size of a fillet weld determined by?

|

the largest equal leg triangle that may be drawn within the cross section of the weld

120102e pg 5 |

|

|

What is a fillet welds strength determined by?

|

it’s effective throat dimension |

|

|

What can excessive convexity lead to on a fillet weld?

|

tends to produce a notch effect

120102e pg 5 |

|

|

What can over welding a joint with a fillet weld lead to?

|

increased distortion

120102e pg 5 |

|

|

What is the size of an unequal leg fillet weld determined by?

|

it’s shortest leg |

|

|

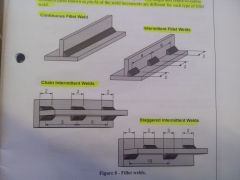

What are the 4 variations of fillet welds?

|

-continuous |

|

|

The length and centre to centre distance of fillet welds is called what?

|

Pitch

120102e pg 7 |

|

|

What joint types are groove welds commonly used with?

|

butt joints

120102e pg 8 |

|

|

What is the size of a groove weld determined by?

|

The throat size |

|

|

Name two factors you use to determine what type of groove weld to use on a joint?

|

-intended service |

|

|

What are square groove welds generally restricted to due to limited penetration?

|

Thin gauge material

120102e pg 9 |

|

|

Where is the bevel groove used most often?

|

Where you only have access to one member of the joint or where the joint is set in the horizontal position |

|

|

What is the most widely used groove joint for materials 9.6mm(3/8”) to 25.4(1”) thickness?

|

Vee Grove

120102e pg 10 |

|

|

What is the advantage of a U-groove weld over a Vee groove?

|

smaller included angle which requires less filler metal

120102e pg 11 |

|

|

What advantage does a J groove weld have over a bevel groove?

|

J groove affords better access for welding, which promotes good penetration and fusion to the bottom of the joint

120102e pg 12 |

|

|

What is a corner joint used mainly on?

|

sheet metal fabrications

120102e pg 14 |

|

|

To make a corner joint stronger what can you add to the inside of the joint?

|

a fillet weld

120102e pg 14 |

|

|

What is an edge joint used extensively to do?

|

join light gauge sheet metal |

|

|

What advantages does edge joining light gauge sheet metal give you?

|

-less danger of burn through |

|

|

What is the disadvantage of edge joints?

|

Cannot withstand dynamic loads

120102e pg 15 |

|

|

How are thin gauge material edge joints generally welded?

|

autogenously(without the need for additional filler metals)

120102e pg 15 |

|

|

What weld are Tee joints generally joined with?

|

fillet welds

120102e pg 15 |

|

|

What is the lap joint highly successful at joining?

|

Metals of different sizes

120102e pg 16 |

|

|

Why are Lap joints preferred for soldering, brazing and braze welding operations?

|

Total joining surface area is greater than that of the butt joint

120102e pg 16 |

|

|

Where maximum strength joint is needed what joint is used?

|

The butt joint

120102e pg 17 |

|

|

In the two digit code 1G what does the |

a)the position

b)the weld type 120102e pg 17 |

|

|

What are the primary considerations in deciding what joint and weld type to use?

|

strength requirements and load conditions |