![]()

![]()

![]()

Use LEFT and RIGHT arrow keys to navigate between flashcards;

Use UP and DOWN arrow keys to flip the card;

H to show hint;

A reads text to speech;

110 Cards in this Set

- Front

- Back

|

Carbon content of piping |

0.1 - 0.2 |

|

|

Which sch has largest ID |

Sch 40 (thinnest walls) |

|

|

Cold bending pipe is what grade and carbon content |

Grade A - low carbon |

|

|

Define grade B piping |

More carbon content - more tensile strength |

|

|

STD pipe pressure rating |

Up to 150 psi (residential) |

|

|

Pressure rating XS |

Up to 200psi (steam,corrosion) |

|

|

XXS pressure rating |

1000 psi and above / hydraulic systems |

|

|

Nps = approximate ID for what sizes |

Up to 12” |

|

|

At what point is piping sized by exact OD |

14” and up |

|

|

What does Schedule stand for |

1000 times pressure/stress ratio |

|

|

Schedule range is |

Sch 10 to sch 160 |

|

|

STD = SCH 40 at what sizes |

1/8 - 10” NPS |

|

|

XS = Sch 80 at what sizes |

1/8 - 8” NPS |

|

|

Which grade of pipe had the thinnest wall thickness and therefore largest ID |

STD |

|

|

Which grade of pipe has thickest wall section and therefore smallest ID for NPS |

XXS |

|

|

What pressure does liquid petroleum operate at and what grade of pipe should be used |

125 psi - XS |

|

|

What type of finish used when very close tolerances required |

Reamed and drifted |

|

|

Finish required for dresser and grip seal fittings, cut square and reamed |

Plain |

|

|

Standard pipe thread on one end |

Threaded finish |

|

|

Can protective couplings be used in fitting instalation |

No |

|

|

Suitable finish for welding |

Beveled |

|

|

What determines max operating pressure |

End finish and joining method |

|

|

CWP |

Cold working pressure |

|

|

G |

Gas |

|

|

O |

Oil |

|

|

S |

Steam |

|

|

S.P |

Steam pressure |

|

|

W |

Water |

|

|

W.O.G |

Water oil or gas |

|

|

WSP |

Working steam pressure |

|

|

Elbow with Female thread one end male end on the other |

Street elbow |

|

|

Identifying tee size 1st 2nd 3rd |

Largest run, smallest run, branch |

|

|

Tee which is not described starting with largest size because of larger branch outlet |

Bull head Tee |

|

|

Nipples available in what sizes |

1/2” increments up to 6”, 1” increments from 7” to 12” |

|

|

Nipple in which threads meet in the middle |

Close nipple |

|

|

Nipple in which a small space is present between threads |

Space nipple |

|

|

Fitting designed for quick assembly and disassembly of piping systems |

Union |

|

|

Iron body with two bronze seats |

Dart union |

|

|

One brass seat one iron seat used on Sch 40 systems |

Rex union |

|

|

Gasket between two seating faces |

Lip union |

|

|

Common use for lip union |

Dielectric union - hot water heaters |

|

|

Used to reduce pipe size in plumbing system |

Bushing |

|

|

Bushing not permitted when installing gas line |

Nesting |

|

|

Heat treated to render it less brittle, shaped by hammering |

Malleable iron |

|

|

Standard fitting aka.. |

Class 150 |

|

|

XH fittings aka |

Class 300 |

|

|

Class 125 and 250 std fittings |

Pressure cast iron |

|

|

Class 2000, 3000, 6000 |

Forged steel fittings |

|

|

Fittings used for drains , waste, venting |

Recessed cast iron |

|

|

Liquid/gas @150•F = 300 psi Steam = 150 psi |

Class 150 malleable iron (std) |

|

|

Steam up to 300 psi Pressure rating for liquid and gas subject to pipe size |

Class 300 malleable iron (xh) |

|

|

Up to 2000 psi for liquid / gas 615 psi for steam Used with Sch 80 pipe |

Class 2000 forged steel |

|

|

Up to 3000 psi liquid/gas 925 psi steam Used with sch 160 |

Class 3000 forged steel |

|

|

Up to 6000 psi liquid /gas 1855 psi for steam Used with XXS pipe |

Class 6000 forged steel |

|

|

No pressure rating |

Recessed cast iron |

|

|

DWV |

Drain waste vent |

|

|

Pressure rating ___________ as temp increases |

Decreases |

|

|

Product used with grooving or vicking of a piping system |

Victaulic |

|

|

A common name for Victaulic |

Groove and shoulder system |

|

|

A common name for Victaulic |

Groove and shoulder system |

|

|

Are victaulic fittings compatible with different manufacturers |

No |

|

|

A common name for Victaulic |

Groove and shoulder system |

|

|

Are victaulic fittings compatible with different manufacturers |

No |

|

|

Why is groove and shoulder so popular |

Simple design |

|

|

Name parts of groove shoulder system |

Two grooved ends, coupling(fitting) with key that prevents pipe from disconnecting, gasket to prevent leaks |

|

|

Name for lengthening of the line due to the play in victaulic couplings |

Creep |

|

|

Why would victaulic fittings leak |

Lack of fluid pressure on gasket |

|

|

Name the two main types of pipe prep for groove and shoulder |

Cut groove, roll groove |

|

|

Name the two main types of pipe prep for groove and shoulder |

Cut groove, roll groove |

|

|

Advantage and disadvantage of cut groove |

Reduces wall thickness but does not restrict interior of pipe |

|

|

Name the two main types of pipe prep for groove and shoulder |

Cut groove, roll groove |

|

|

Advantage and disadvantage of cut groove |

Reduces wall thickness but does not restrict interior of pipe |

|

|

Advantage and disadvantage of roll groove |

Wall thickness not effected but internal diameter reduced by depth of groove |

|

|

Minimum sch for cut groove |

schedule 40 |

|

|

Minimum sch for cut groove |

schedule 40 |

|

|

Type of cut groove used on soft material |

Radius cut groove |

|

|

Lightest wall thickness for roll groove |

Schedule 10 |

|

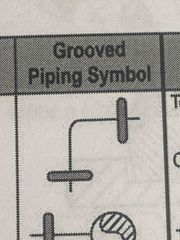

What symbol is this |

Grooved 90•elbow |

|

|

Water has no deteriorating effect on what type of gasket |

Elastomer (composite rubber) |

|

|

Gasket can be used for hot water service up to 230•F on a continuous basis (works well on hot water heater) |

Grade E |

|

|

Choose gasket according to what |

Manufacturers spec and type of liquid flowing through system |

|

|

How are gaskets identified |

Permanent coloured stripe |

|

|

What will guarantee gasket failure |

Installing gasket not resilient to certain chemicals |

|

|

Sch 40 A-53 gr. B threaded can sustain pressure up to _________ and is used for ____________ work |

150 psi , residential |

|

|

Division B Section 2.2 Plumbing code of Canada |

Materials and equipment, ferrous pipe and fittings |

|

|

Division B section 2.3 Plumbing code of Canada |

Piping - construction and use of threaded joints and connections. Protection support and testing of ferrous pipe |

|

|

B149 section 6 |

Nat Gas and propane code - piping and tubing systems, ferrous pipe used for gas distribution |

|

|

ASME B-31 |

Power piping code - including steam or vapour over 15 psi and high temp water exceeding 160 psi or 250•F |

|

|

API |

American petroleum institute |

|

|

API |

American petroleum institute |

|

|

ASTM |

American society for testing and materials |

|

|

ASME |

American society of mechanical engineers |

|

|

ASME |

American society of mechanical engineers |

|

|

AWWA |

American water works association |

|

|

ASME |

American society of mechanical engineers |

|

|

AWWA |

American water works association |

|

|

Csa |

Canadian standards association |

|

|

ASME |

American society of mechanical engineers |

|

|

AWWA |

American water works association |

|

|

Csa |

Canadian standards association |

|

|

Define stress |

Resistance to deformation |

|

|

Advantage and disadvantage of single wheel cutter |

360 swing, only internal burr |

|

|

Increase pressure on cutter with handle by no more than _____ turn per revolution |

1/4 |

|

|

Increase pressure on cutter with handle by no more than _____ turn per revolution |

1/4 |

|

|

Never use a spiral reamer with a power vise T or F |

T |

|

|

Which end gets joining compound and why |

Male end only avoid lubricant in system |

|

|

Which end gets joining compound and why |

Male end only avoid lubricant in system |

|

|

How many wraps of Teflon tape |

1 1/2 |

|

|

O2 lines cleaned with what |

Tetrachloride |

|

|

What rate does NPT taper enlarge at |

3/4 per foot |