![]()

![]()

![]()

Use LEFT and RIGHT arrow keys to navigate between flashcards;

Use UP and DOWN arrow keys to flip the card;

H to show hint;

A reads text to speech;

14 Cards in this Set

- Front

- Back

|

the maximum stress that a material can bear before breaking when it is allowed to be stretched or pulled. |

Tensile Strength |

|

|

Apparatus needed to test the tensile strength or compressive strength |

Universal Testing Machine (UTM) |

|

|

It is a machining tool usually designed to shape metal or wood. The primary purpose of this tool is to eliminate unnecessary material and leave a perfectly formed workpiece behind. |

Lathe Machine |

|

|

is the operation of cutting the perpendicular end of a workpiece to the rotating axis. During the this process, the tool moves around the radius of the workpiece, removing a small layer of material to generate the appropriate component length and a smooth face surface. |

Facing |

|

|

Step turning produces two surfaces with a sharp difference in diameters between them. The last feature is similar to a step. |

Step Turning |

|

|

Taper turning creates a ramp transition between two surfaces with differing diameters due to the angled motion of the workpiece and a cutting. |

Taper Turning |

|

|

Shows the behavior of the material under increasing stress. It shows us the material’s proportionality limit, yield point, ultimate tensile strength, and point of fracture. |

Stress-strain Diagram |

|

|

is the point in the stress- strain diagram wherein the strain-load relationship transitions from a linear to a non-linear form and starts to curve. |

Proportionality Limit |

|

|

the point where the material begins to elongate without increasing in tensile force. This is the point in which the material transitions from elastic to plastic deformation. |

Yield Point |

|

|

is the point where the material begins to elongate without increasing in tensile force. This is the point in which the material transitions from elastic to plastic deformation. |

Ultimate Strength |

|

|

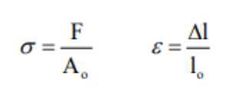

Formula for Stress and Strain: |

|

|

|

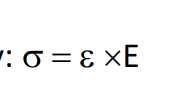

Formula for Stress given with Modulus of Elasticity: |

|

|

|

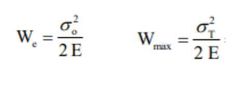

Formula for modulus of elastic resilience and maximum elastic energy |

|

|

|

Formula for fracture work: |

|