![]()

![]()

![]()

Use LEFT and RIGHT arrow keys to navigate between flashcards;

Use UP and DOWN arrow keys to flip the card;

H to show hint;

A reads text to speech;

62 Cards in this Set

- Front

- Back

|

What is the stored energy on an exposed film called |

Silver Halide Crystals |

|

|

The processed film was underdeveloped, what would cause this |

Not enough developing time Developer temperature too low Depleted developer solution Contaminated developer solution |

|

|

Film was exposed to light when the door was opened, this would cause the film to be |

Black |

|

|

In the film processing step the rinsing step is necessary because |

Rinsing removes the developer from the film & stops the development process |

|

|

The film emulsion is hardened during what process |

Fixation |

|

|

The processed film has a straight white border on one side |

Developer Solution Too Low |

|

|

The processed film is dark because of overdevelopment what would cause this |

Too much developing time Developer temperature to high Concentrated developer |

|

|

The processed film has a straight black border on one side |

Fixer solution too low |

|

|

The optimal temperature for developer solution is |

68 Degrees |

|

|

What are the film processing steps in order |

Development Rinsing Fixing Washing Drying |

|

|

The hydroquinone in the developer brings out the ________ tones, wheres the Elon in the developer brings out the ________ tones on a dental radiograph |

Black Gray |

|

|

The safe light must be placed a minimum of what distance from the film and the word area |

4 Feet |

|

|

Unopened boxes of x-ray film should not be stored in the darkroom because |

Chemical fumes from processing solutions may for the film |

|

|

The thermometer for manual processing should be placed in the |

Developer Solution |

|

|

at 68F what is the optimal development time for manual film processing |

6 Minutes |

|

|

Why is a replenisher added to the processing solution |

Compensate for the loss of solution strength Ensure uniform results between solution changes Compensate for the loss of volume of solution Compensate for oxidation |

|

|

What can be used to clean the processing tank |

Commercial Tank Cleaner Hydrochloric Acid and Water Solution |

|

|

A breakdown of chemicals in the processing solution that results from exposure to air |

Oxidation |

|

|

The superconcentrated solution is added to the processing solution to compensate for the effects of oxidation |

Replenisher |

|

|

Converts the exposed silver halide crystals to black metallic silver and generates the black areas on the radiograph |

Developing Solution |

|

|

Removes the unexposed silver halide crystals and created white areas on the radiograph |

Fixer Solution |

|

|

What chemicals are used in the Developing Agent |

Hydroquinone Elon |

|

|

What chemicals are used in the Preservative |

Sodium Sulfite |

|

|

What chemicals are used in the Accelerator |

Sodium Carbonate |

|

|

What chemicals are used in the Restrainer |

Potassium Bromide |

|

|

What chemicals are used in the Fixing Agent |

Ammonium Thiosulfate Sodium Thiosulfate |

|

|

What chemicals are used in the Hardening Agent |

Potassium Alum |

|

|

What chemicals are used in the Acidifier |

Acetic Acid Sulfuric Acid |

|

|

What is the role of the water bath/washing in processing |

Wash the film after fixation to remove all excess chemicals from the emulsion |

|

|

Whats the appearance of the processing error for fogged film |

Gray |

|

|

Whats the appearance of the processing error for overdeveloped film |

Dark |

|

|

Whats the appearance of the processing error for underdeveloped film |

Light |

|

|

Whats the appearance of the processing error for light leak |

Black |

|

|

Whats the appearance of the processing error for developer cutoff |

Straight White Border |

|

|

Whats the appearance of the processing error for fixer cutoff |

Straight Black Border |

|

|

Underdeveloped Film |

|

|

Overdeveloped Film |

|

|

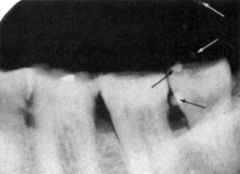

Reticulation of Emulsion |

|

|

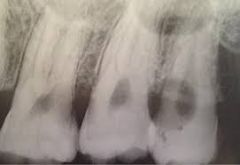

Fixer Spots |

|

|

Developer Cutoff |

|

|

Fixer Cutoff |

|

|

Overlapped Film |

|

|

Air Bubbles |

|

|

Black Fingerprint |

|

|

Static Electricity |

|

|

White Light |

|

|

Fogged Film |

|

|

|

|

|

Fingernail Artifact |

|

|

Scratches |

|

|

What would cause film to be underdeveloped |

Inadequate development time Developer solution too cool Inaccurate timer or thermometer Depleted or contaminated solution |

|

|

What would cause film to be overdeveloped |

Excessive developing time Developer solution too hot Inaccurate timer or thermometer Concentrated solution |

|

|

What would cause reticulation of emulsion |

Sudden temperature change between developer and water bath |

|

|

What would cause developer spots |

Developer comes in contact with film before processing |

|

|

What would cause fixer spots |

Fixer comes in contact with film before processing |

|

|

What would cause yellow brown stains |

Exhausted developer or fixer Insufficient fixation time or rinsing |

|

|

What would cause developer cutoff |

Low level of developer |

|

|

What would cause fixer cutoff |

Low level of fixer |

|

|

What would cause overlapped films |

Two films contacting each other during processing |

|

|

What would cause air bubbles |

Air trapped on the film surface after being placed in processing solution |

|

|

What would cause static electricity |

Film packet is opened quickly |

|

|

What would cause fogged film |

Improper safelighting Light leaks Outdated films Improper film storage Contaminated solutions Developer too hot

|