![]()

![]()

![]()

Use LEFT and RIGHT arrow keys to navigate between flashcards;

Use UP and DOWN arrow keys to flip the card;

H to show hint;

A reads text to speech;

138 Cards in this Set

- Front

- Back

|

Who tests the quality of raw materials in South Africa?

|

The South African Textile Federation

|

|

|

What kind of information can a manufacturer attach to a label on their raw materials?

|

Colour fastness ; Crease resistance

Fibre content ; Moth proofness |

|

|

What may be the cause of problems with colour?

|

Poor selection and use of dyes

Inferior application methods Poor quality dyes |

|

|

How do you perform a dry cleaning test?

|

Stretch sample over hoop.

Rub well with a cotton rag dampened in dry cleaning solvent. Staining on rag proves dye affected by dry cleaning. Soak sample in dry cleaning solvent for 10 minutes. Stir occasionally . Check to see if solvent is coloured. |

|

|

How do you perform a friction test?

|

Rub test sample hard and well for several seconds with clean, dry, white cotton swab.

Tells if will stain underwear. |

|

|

How do you perform a laundry test?

|

Mix laundry detergent.

Attach sample to clean white cotton sample. Place sample in flask with detergent Shake well, leave to stand and repeat. Note colour of detergent Rinse sample twice and note colour of water. Allow sample to dry, compare with control sample and look at white fabric |

|

|

How is the sunlight test performed?

|

In a dark cupboard with very strong ultra violet light burning.

Time is calculated with the intensity of the light to determine amount of sunlight hour exposure. |

|

|

Define fugative colours

|

Colours that are affected by heat.

Discolouration caused by heat disappears on cooling, |

|

|

What is caused by too high a temperature on fabrics?

|

Changes in colour

Scorching |

|

|

How is the influence of damp heat tested?

|

Use a steam iron or damp pressing cloth,

Compare ironed cloth with control sample. |

|

|

Define pilling

|

The formation of tiny balls by the fibre caused by friction.

|

|

|

How does pulling occur?

|

When fibre catches and yarn pulls easily

|

|

|

How does one test for pilling and pulling?

|

Sample stretched over a frame and placed in a testing cabinet.

Metal balls with burrs on inside of the cabinet cause friction when power switched on causing cabinet to tumble. The burrs catch on the fabric causing pilling and pulling. |

|

|

How is the durability of fabric determined?

|

Degree of pilling and pulling is established and calculated.

|

|

|

Name the three quality standards for stitches

|

Correctly formed without kinks or loops

Correct stitch type Correct stitch length and density |

|

|

What are the six quality standards for stitchings?

|

Correct tension

Threads must be balanced, so loops not visible on either surface Thread colour suitable for fabric colour Correct type of thread for fabric's fibre content Thread heat and abrasion resistant Firm and not unpick at the edges |

|

|

Where are open seams used?

|

Long seams such as side-, centre front- and centre back-seams

|

|

|

Where are closed seams used?

|

Circular seams such as waist and armhole seams

|

|

|

Where are enclosed seams used?

|

Cuffs, facings and collars

|

|

|

Name three types of single stitched seams

|

Open seam

Closed seam Enclosed seam |

|

|

Name two types of double stitched seams

|

French seams

Flat-felled or "run-and-fell" seams |

|

|

Where are double stitched seams used?

|

Children's wear

Shirts Pyjamas Denim jeans Denim skirts |

|

|

Define seam

|

A join consisting of consecutive stitches holding layers or plies of material together

|

|

|

Define super imposed

|

Laying one or more plies of material on one another so that edges to be joined are aligned.

|

|

|

Define stitch

|

A unit of thread conformation resulting from passing thread/s, or loop/s of thread into or through a material.

|

|

|

Define stitching

|

A sequence of stitches for finishing an edge or for ornamental purposes or for both.

|

|

|

Define strip

|

A piece, ply or portion detached from material, in relatively narrow width and long length;

including binding, interlining, and reinforcing tape and webbing |

|

|

Name the seven classes of stitches

|

Single thread basting stitch

cobbler's or sadler's stitch Single needle lock stitch Multi thread chain stitch Overedge or overlock stitch Floss stitch Single thread lock stitch |

|

|

What is the name of class 100 stitches?

|

Single thread basting stitch

|

|

|

How is a single thread basting stitch formed?

|

With one or two needle threads

A loop of each thread is passed through material and secured by interlooping the loops by succeeding loop or loops to form a stitch |

|

|

What is the general characteristic of class 100 stitches?

|

Interlooping

|

|

|

What is the name of the class 200 stitches?

|

Cobbler's or sadler's stitch

|

|

|

What is a cobler's or sadler's stitch?

|

A hand sewn stitch worked with two threads which are passed simultaniouly through the upper and lower surface of the material through the same holes

|

|

|

What is the name of the class 300 stitches?

|

Single needle lock stitch

|

|

|

How are the single needle lock stitches formed?

|

Formed with two threads.

Loops from the first thread is pushed from the top surface through the material which is interlaced by the second thread from the bottom. The two threads are usually a needle and a bobbin thread. |

|

|

What are the characteristics of the class 300 stitches?

|

The interfacing of threads between the surfaces of the material

|

|

|

How are class 400 stitches formed?

|

Two groups of threads form the stitch when the first group from the upper surface is pushed through the material and a loop forms which is interlaced by the second group from the bottom

|

|

|

What is the name of the class 500 stitches?

|

Overedge or overlock stitch

|

|

|

What is the characteristic of overedge or overlock stitches?

|

Loops formed over the edge of the material by one group of threads and caught by the other thread or threads to neaten the edge.

|

|

|

How are class 500 stitches formed?

|

Combinations of stitches are formed by rows of stitch types from two or more stitch classes.

These are sewn simultaneously. |

|

|

What is the name of the class 600 stitches?

|

Floss stitch

|

|

|

How are floss stitches formed?

|

Groups of threads form loops and stitchings on the surface of the seam in order to cover it so that the seam is flat and both right and wrong sides are neatened.

|

|

|

What is the name of the class 700 stitches?

|

Single thread lock stitch

|

|

|

How are single thread lock stitches formed?

|

Formed with one continuous needle thread that interlaces with the bobbin thread between the surfaces of the material.

|

|

|

What is the common characteristic of class 700 stitches?

|

When the first stitch penetrates the needle thread is apportioned into two groups and the one part is wound as a bobbin thread

|

|

|

What are the four classes of seams?

|

SS

LS BS FS |

|

|

What is the class SS?

|

Super imposed

|

|

|

What is the general characteristic of the class SS

|

The laying up of all the plies of material with the edges aligned and sewn together with one or more rows of stitchings.

|

|

|

What does the class LS stand for?

|

Lapped seam

|

|

|

What is the characteristic of the LS class of seams?

|

The seam is joined by one or more stitchings

|

|

|

What is the class BS called?

|

Bound seam

|

|

|

What is the characteristic of class BS seams?

|

Encasing of a layer or layers of the seam in a strip of material or a binding and securing it with one or more rows of stitchings

|

|

|

What is the name of the class FS?

|

Flat seam

|

|

|

What does the letter in the name of a seam in a seam class indicate?

|

The amount of times the seam edge is folded.

|

|

|

What are the six quality standards for seams?

|

Sturdy

Suited to the garment and positioning Width must be suitable for fabric, garment and seam type Stitchings straight and equidistant to the seam edge Thread suitable to the colour, fabric weight and fibre content All seam and stitching quality standards |

|

|

What are the two stitching classes?

|

Class OS

Class EF |

|

|

What type of stitchings are represented in class OS

|

Ornamental stitchings

|

|

|

What is the characteristic of the OS class?

|

Series of stitches in a straight line, curve or according to a pattern is applied to the surface of the material

|

|

|

What type of stitchings are represented in class EF?

|

Edge finishings

|

|

|

What is the general characteristic of the EF class?

|

Series of stitches sewn on or over the edge of the material (the edge may or may not be folded) to neaten the edge, or sewn on or at the folded edge to attach the edge to the main part of the the material

|

|

|

How wide should a plain hem be?

|

2 - 5 cm

|

|

|

How wide should the hem for a flared skirt be?

|

2 cm

|

|

|

How wide should the hem for straight and A-line skirts be?

|

3 - 5 cms

|

|

|

How is a plain hem stitched?

|

Two folds are made and it is sewn with one or two rows of stitchings of an appropiate stitch.

|

|

|

Describe hemming stitch type 103

|

Straight and wide skirts, sleeves, facings.

It's applicable to single and plain hems |

|

|

Describe hemming stitch type 301

|

Rolled hems, plain and double stitched

|

|

|

Name the seven quality standards for hems and hem stitchings

|

Hem width is even

All stitch and stitching quality standards Hems flat and not wrinkled Stitchings not visible on right side Correctly well-pressed Stitchings secure at beginning and end Hems hang evenly |

|

|

Name three types of hems?

|

Plain hem

Rolled hem Single hem |

|

|

What is the width of rolled seams?

|

3 - 5 mm

|

|

|

Where are rolled hems used?

|

Circular skirts

Frills Lingerie Soft, sheer and drappy fabric |

|

|

How is a rolled hem stitched?

|

Sewn with a hemming foot

|

|

|

What is the width of a single seam?

|

3 - 5 cm

|

|

|

Where is a single hem used?

|

Medium to heavy weight straight and A-line skirts

Sleeves of light weight blouses and dresses Sleepwear Knits |

|

|

How is a single hem stitched?

|

Fold the hem only once

When sewing a double knit, neatening the raw edge isn't required. Single knits need to have the raw edge overlocked. |

|

|

What are the six quality standards for trimmings?

|

Same laundering care processes as garment

Colour fast Attached securely Neat appearance In proportion and harmony with garment or garment part Durable, lasting the same time as the garment |

|

|

What are the four quality standards for fasteners?

|

Must be suitable for type of opening, garment and position on garment

Durable Colour suitable Attached securely |

|

|

What are the eleven quality standards for buttons and buttonholes?

|

Buttons slide through holes easily

Buttons not too big Buttonholes neat and sturdy No loose threads visible Buttonholes fit in on facings Buttons securely attached without loose thread ends Even spacing between buttonholes Buttons not extend over edge when opening buttoned up Placed on double fabric preferably interfaced Buttonhole thread match garment colour Buttons durable not crack or fade |

|

|

What are the four quality standards for press studs, poppers, hooks and eyes?

|

Attached securely

Sewing invisible on outside Poppers and studs attached securely Parts of poppers and studs fit into each other securely |

|

|

What are the two quality standards for buckles?

|

Metal - not rust, tarnish or peel

Plastic and nylon - not fade, melt or loose gloss in laundering |

|

|

What are the four qualities of zip fasteners?

|

Invisible on outside unless decorative

Weight compatable with garment fabric Colour match garment All stitch and stitching quality standards |

|

|

What are the five quality standards for finishing and packing?

|

Pressing neat without wrinkles or creases

No shine Hems, seams and pleats not over pressed Garments folded neatly without wrinkles or bundles of folds inside packages Fit neatly into packages |

|

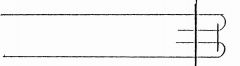

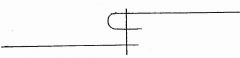

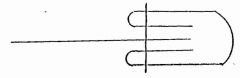

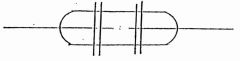

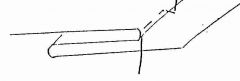

What is this stitch type number and name?

|

301

Single needle lock stitch |

|

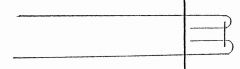

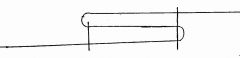

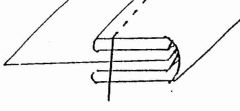

What is this stitch type number?

|

302

|

|

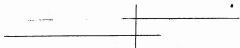

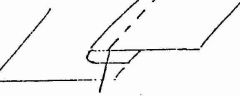

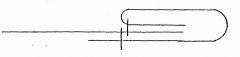

What is this stitch type number and name?

|

304

Zigzag lock stitch |

|

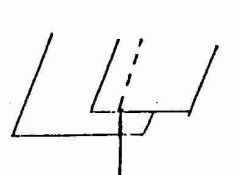

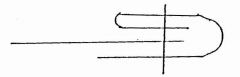

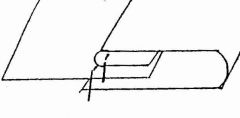

What is this stitch type number?

|

401

|

|

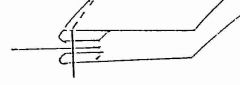

What is this stitch type number and name?

|

402

Cover seam stitch |

|

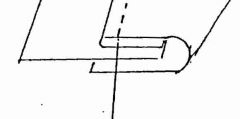

What is this stitch type number?

|

503

|

|

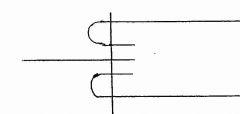

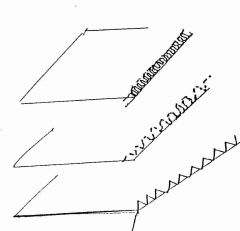

What is this stitch type number and name?

|

504

Three thread overlock stitch |

|

What is this stitch type number?

|

516

|

|

What is this stitch type number?

|

601

|

|

What is this stitch type number?

|

701

|

|

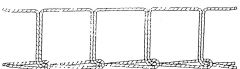

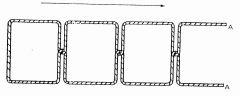

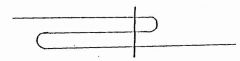

What is this seam type number?

|

SSa-1

|

|

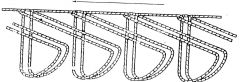

What is this seam type number?

|

SSb-1

|

|

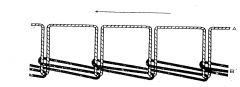

What is this seam type number?

|

SSc-1

|

|

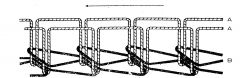

What is this seam type number?

|

SSe-2

|

|

What is this seam type number?

|

SSae-2

|

|

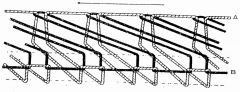

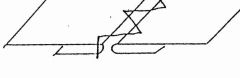

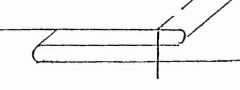

What is this seam type number?

|

LSa-1

|

|

What is this seam type number?

|

LSa-1

|

|

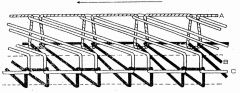

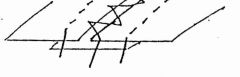

What is this seam type number?

|

LSb-1

|

|

What is this seam type number?

|

LSb-1

|

|

What is this seam type number?

|

LSe-1

|

|

What is this seam type number?

|

LSe-1

|

|

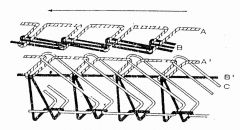

What is this seam type number?

|

LSr-2

|

|

What is this seam type number?

|

LSr-2

|

|

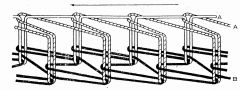

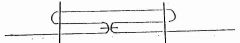

What is this seam type number?

|

BSa-1

|

|

What is this seam type number?

|

BSa-1

|

|

What is this seam type number?

|

BSb-1

|

|

What is this seam type number?

|

BSb-1

|

|

What is this seam type number?

|

BSc-1

|

|

What is this seam type number?

|

BSc-1

|

|

What is this seam type number?

|

BSF-2

|

|

What is this seam type number?

|

BSF-2

|

|

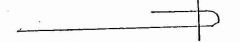

What is this seam type number?

|

FSa-1

|

|

What is this seam type number?

|

FSa-1

|

|

What is this seam type number?

|

FSb-1

|

|

What is this seam type number?

|

FSb-1

|

|

What is this seam type number?

|

FSc-1

|

|

What is this seam type number?

|

FSc-1

|

|

What is this seam type number?

|

FSd-3

|

|

What is this seam type number?

|

FSd-3

|

|

What is this seam type number?

|

FSe-1

|

|

What is this seam type number?

|

FSe-1

|

|

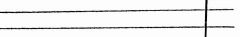

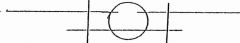

What is this stitching type number?

|

OSa-1

|

|

What is this stitching type number?

|

OSa-1

|

|

What is this stitching type number?

|

OSc-1

|

|

What is this stitching type number?

|

OSc-1

|

|

What is this stitching type number?

|

OSe-1

|

|

What is this stitching type number?

|

OSe-1

|

|

What is this stitching type number?

|

OSg-3

|

|

What is this stitching type number?

|

OSg-3

|

|

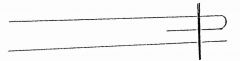

What is this stitching type number?

|

EFa-1

|

|

What is this stitching type number?

|

EFa-1

|

|

What is this stitching type number?

|

EFb-1

|

|

What is this stitching type number?

|

EFb-1

|

|

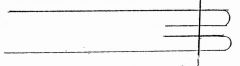

What is this stitching type number?

|

EFc-1

|

|

What is this stitching type number?

|

EFc-1

|

|

What is this stitching type number?

|

EFd-1

|

|

What is this stitching type number?

|

EFd-1

|