![]()

![]()

![]()

Use LEFT and RIGHT arrow keys to navigate between flashcards;

Use UP and DOWN arrow keys to flip the card;

H to show hint;

A reads text to speech;

199 Cards in this Set

- Front

- Back

|

Name ten techniques for spreading fabrics

(10) |

On the fold; Face up;

Back up; Face to Face; Back to back; Stripes, checks and plaid; One-way design; Mock fur; Velvet; Leather |

|

|

For what reason would you use the on the fold spreading technique?

(1) |

When knits are done in a tube.

|

|

|

Describe the face up spreading technique

(1) |

All plies are spread with the face, or right

side up. |

|

|

Describe the back up spreading technique

(1) |

All plies are placed with the back, or wrong side, up.

|

|

|

Describe the face to face spreading technique

(1) |

The right sides are spread facing each other.

|

|

|

How do you lay-up stripes, checks and plaids?

(2) |

Each lay is started with the same stripe or colour.

Check spikes or cloth clamps are used to keep it in position |

|

|

How do you spread one-way designs?

(2) |

Face up;

Design runs in same direction |

|

|

How do you spread mock fur?

(2) |

Single ply;

wrong side |

|

|

How do you spread velvet?

(2) |

Only 4 - 6 plies;

Face up (One-way) |

|

|

How do you spread leather?

(3) |

Single ply;

Back up, Rotary blade (Cut around odd marks) |

|

|

How do you supply power to electric cutters?

(3) |

Overhead;

From rods or rails; Only enough cable so no coils on table |

|

|

Name the two types of steam irons

(2) |

Reservoir and Flash;

Steam iron |

|

|

How do the reservoir and flash irons work?

(3) |

Water enters iron from 2L tank or reservoir;

Water flows over element; flow of water controlled by thumb knob |

|

|

How do steam irons work?

(1) |

Fed from central steam supply

|

|

|

What are the disadvantages of steam irons?

(4) |

Complicated;

Expensive; If a fault arises all irons are unusable; noisy |

|

|

Where are steam irons used?

(1) |

Very large factories

|

|

|

Name three types of pressing machine

(3) |

Pressing machines;

vacuum tables; Fusing presses |

|

|

What are the parts of the pressing machine?

(3) |

table;

buck ; shoe |

|

|

Which part of the pressing machine is stationary?

(1) |

Buck

|

|

|

Which part of the pressing machine is moved and how?

(3) |

Shoe;

hand; foot pedal |

|

|

Which part of the pressing machine houses the element?

(1) |

shoe

|

|

|

What are vacuum tables used for?

(1) |

Drying pressed garments

|

|

|

How do vacuum tables work?

(1) |

Suction draws moisture away

|

|

|

What are the types of fusing presses?

(2) |

Flat;

Roller |

|

|

What are fusing presses used for?

(1) |

Fusing resin fusable interfacing fabrics

|

|

|

What varies when using different types of interfacing fabrics?

(3) |

Time;

Heat; Pressure |

|

|

What problems can occur when fusing interfacing fabrics?

(2) |

Strike through;

Strike back |

|

|

How are problems caused when fusing interfacing fabrics?

(3) |

Incorrect time;

heat; pressure for weight of fabric |

|

|

What is strike through?

(2) |

Resin layer of interfacing fabric melts through fabric;

White markings visible on outside |

|

|

What is strike back?

(2) |

Resin layer deposit forms on shoe or roller;

Fuses onto next garment |

|

|

Why must workflow be carefully planned?

(3) |

Optimal production;

Save time; Save labour |

|

|

What needs to be ensured when designing workflow?

(4) |

Shortest routes;

no delay; no bottling up; no crossing routes |

|

|

Name the five types of equipment in the cutting room:

(5) |

Cutting table,

Cutting machines, Laying-up/Spreading machines, Marking machines and Ticketing machines |

|

|

Name the six requirements for cutting tables:

(6) |

Strong; Sturdy;

Smooth and durable finish; Correct height; Length; Width |

|

|

What is the width of a cutting table determined by?

(2) |

The type of fabric and the

laying-up technique used |

|

|

What is the width of the cutting table needed for knits? Why?

(2) |

Narrow table ;

They are layed-up on the fold |

|

|

What type of fabrics need cutting tables of 160 - 170 cm wide? Why?

(4) |

Fashion fabrics;

Plaids Checks; They are spread on the open. |

|

|

Name the two types of cutting machines:

(2) |

Straight knife/blade ;

Circular blade/Round knife |

|

|

How does the straight knife cutting machine work?

(2) |

They glide on a base which slides underneath the fabric ;

The blade cuts in a vertical motion |

|

|

What are the benefits of the straight knife cutting machine?

(3) |

Handles easily;

Manoeuvrable around sharp tight corners ; cuts nips easily |

|

|

Which type of cutting machine needs its knife removed for sharpening?

(1) |

Straight knife/blade

|

|

|

How does the circular blade cutting machine work?

(2) |

The base slides underneath the fabric;

Cutting is done with a rotary action. |

|

|

What are the drawbacks of the circular blade cutting machine?

(2) |

Not effective around corners;

Cutting nips is not accurate. |

|

|

What is the purpose of the differential grinder in the rotary knife cutter?

(1) |

Keeps the blade sharp

|

|

|

What is the purpose of the safety shield in the rotary knife cutter?

(1) |

Prevents accidents

|

|

|

What is the purpose of the rotary blade in the rotary knife cutter?

(1) |

Cuts through fabric piles

|

|

|

What is the purpose of the base plate in the rotary knife cutter?

(1) |

Guides for cutting accuracy

|

|

|

What is the purpose of the control handle in the rotary knife cutter?

(1) |

For manoeuvrability of the machine

|

|

|

What are the two advantages of laying-up machines?

(2) |

Labour-saving

Accurate |

|

|

What are the five disadvantages of laying-up machines?

(5) |

Expensive;

Needs special tables; Heavy; Fabric is more stretched; Less accurate with striped and check fabrics |

|

|

What is meant by the selvedge grain?

(1) |

The band of more tightly woven fabric that runs up

either side of the fabric's meterage |

|

|

Name the three types of marking machines:

(3) |

Hot drill;

Thread marker; Hot Notcher |

|

|

Where are pocket and dart points marked?

(1) |

1 cm inside the point

|

|

|

How does the hot drill marking machine work?

(3) |

Circular base placed under fabric at position for marking;

Lower the drill down into fabric; A small hole is burned into the fabric pile. |

|

|

Which two types of fabrics can you not use the hot drill on? Why not?

(3) |

Natural fibres;

knits; They will run |

|

|

Why is polyester easily marked by the hot drill?

(1) |

Heat sensitive so melts

|

|

|

What types of fabrics are appropriate to use a thread marker on?

(3) |

Silk,

velvet, very fine natural fabrics |

|

|

What two parts make up a thread marker?

(2) |

spoolpin;

needle |

|

|

How does the thread marker work?

(3) |

A needle is lowered into the fabric;

the stitch is caught underneath and snipped; leaving a thread loop as the needle rises. |

|

|

Which marking machines can be used to mark pocket and dart positions?

(2) |

Hot drill ;

Thread marker |

|

|

What is a hot notcher used for?

(5) |

To mark accurate 2mm nips for;

seam widths; Hem widths; pleats; other match points |

|

|

How does a ticketing machine work?

(2) |

It prints and ;

sticks coded stickers onto garment pieces. |

|

|

Why do garment pieces need to be ticketed?

(5) |

To ensure correct assembly ;

Misplaced parts can be placed in the correct bundle; Garment parts can be checked; Determine when parts go missing; workers can be traced |

|

|

What do the codes printed by ticketing machines show?

(4) |

Size

part colour style |

|

|

What is a marker?

(1) |

A plan of how to lay-out the pattern pieces on the fabric.

|

|

|

What are the eight requirements for a marker?

(8) |

Width is the same as fabric; Parts are economical;

Parts don't overlap; long and straight edges are aligned; Small pieces fit into larger spaces; Keep selvedge grain in mind; Use thin clear making pen to trace parts onto marker paper; check the whole marker again |

|

|

What should you check your marker for?

(4) |

All parts marked;

Parts lie correctly; No waste; Saves time and labour |

|

|

What is another name for a ticketing machine?

(1) |

Sober machine

|

|

|

What methods of transporting work in a factory

(2) |

Plastic crates ;

Conveyer belts |

|

|

Define the term "Chartering Conventions"

(3) |

Policies that are applicable to all processes on flow charts

|

|

|

Name the three chartering conventions

(6) |

Heading; Structure and description (vertical

symbol followed by description); Connection of subdivisions or components indicated by horizontal line at vertical point of connection |

|

|

Name the two methods of arranging workstations

(2) |

Line stations;

Island stations |

|

|

What are line stations?

(1) |

Workstations follow each other in a horizontal line.

|

|

|

What are island work stations?

(1) |

Workstations arranged in groups of 3 or 4 face each other.

|

|

|

When and why are island work stations effective?

(2) |

When processes consist of 3 or 4 operations;

Space is saved from transport lanes. |

|

|

What spaces need to be left around workstations

(4) |

Transport avenue

aisle for supervisor and worker use; Behind and in front of the workflow. |

|

|

Why should workers not sit with backs to the wall?

(4) |

Feel confined;

No avenue for emergency, supervisor or mechanic |

|

|

What are the characteristics of industrial machines?

(7) |

One function; Big;

Mounted on stand; Thick and sturdy tabletop; One horsepower single- or three phase motor; Greater speed; Expensive |

|

|

What is another name for a straight sewing lock stitch machine

(1) |

Plain sewer

|

|

|

How is a lock stitch formed?

(2) |

Formed by a needle and bobbin thread

Hooked through the centre of the fabric ply. |

|

|

Name two types of lock stitch machine

(2) |

Straight sewing lock stitch machine

Zig-zag lock stitch machine |

|

|

How does a zig-zag lock stitch machine differ from the plain sewer?

(1) |

The needle bar swings left and right, forming a zig-zag

|

|

|

Name two types of chain stitch machine

(2) |

Single thread chain stitch machine

Double chain stitch machine |

|

|

What are single thread chain stitches used for?

(1) |

Decorative stitchings

|

|

|

What is a double thread chain stitch machine used for?

(1) |

Seams in trousers

|

|

|

How does the double thread chain stitch machine differ from the single thread one?

(3) |

More elastic

Stronger Subjected to more strain |

|

|

Name three types of general function machine

(3) |

Lock stitch machine

Chain stitch machine Double and multi-needle machines |

|

|

What are the two ways that double needle machine can work

(2) |

Two bobbins

Two spreaders |

|

|

Which stitch do double needle machines that use bobbins use?

(1) |

Lock stitch

|

|

|

Which stitch do double needle machines that have spreaders use?

(1) |

Chain stitch

|

|

|

What fabric is usually sewn using a chain stitch double needle machine?

(1) |

Denim

|

|

|

Name five special function machines

(5) |

Buttonhole machines

Bar tacking machines Button sewing machines Blind stitch machines embroidery machines |

|

|

Name two types of buttonhole machines

(2) |

Double bar (Shirt) buttonhole machine

Key hole buttonhole |

|

|

Describe how the Double bar buttonhole machine functions.

(5) |

Uses a bobbin and bobbin case

Sews a zig-zag stitch Blade cuts hole open Automatic thread cutter The stitch length, width and density are adjustable |

|

|

Describe how the keyhole buttonhole machine functions.

(4) |

Double thread chain stitch

Blade cuts hole open Automatic thread cutter Size is adjustable |

|

|

What are the requirements of thread for a buttonhole machine?

(2) |

Strong

Correct twist |

|

|

What do you need to do when you change the buttonhole size being made by a buttonhole machine?

(1) |

Change the blade

|

|

|

What is the purpose of a bar tacking machine?

(4) |

Attaching belt carriers (loops)

Reinforcing fly base, pocket ends, pleats |

|

|

What stitch does the bar tacking machine use?

(1) |

zig-zag

|

|

|

How does the button sewing machine function?

(3) |

Chain stitch

One needle and spreader Button held in spring clamp |

|

|

What kind of buttons can a button sewing machine sew on?

(6) |

Two holes

Four holes With attachment: hooks, eyes, press studs and buttons with a shank |

|

|

What is another name for a blind stitch machine?

(1) |

Blind hemmer

|

|

|

What stitch does a blind stitch machine use?

|

Chain stitch

|

|

|

Describe the needle in a blind stitch machine?

(2) |

Curved

positioned horizontally |

|

|

What is the width of hems that a blind stitch machine can sew?

(1) |

5mm - 8mm

|

|

|

What stitch does an embroidery machine use?

(1) |

Chain stitch

|

|

|

How many heads can operate on an embroidery machine?

(1) |

12 - 25

|

|

|

How many colour threads can each head of an embroidery machine sew with at once?

(1) |

three

|

|

|

Name two finishing machines

(2) |

Serging machine

Overlocker |

|

|

How does a serging machine function?

(2) |

Two threads

One needle and one looper |

|

|

For what purpose would you use a serging machine?

(1) |

Serging long seams

|

|

|

What is the benefit of a serging machine?

(1) |

Cheaper than overlocking

|

|

|

How many threads can overlockers function with?

(1) |

3 - 4

|

|

|

How do the mechanics of a three and four thread overlocker differ?

(2) |

Three threads = 1 needle and 2 loopers

Four threads = 2 needles and 2 loopers |

|

|

For what reason would you use a differential feed overlocker?

(2) |

Gathers

Knits |

|

|

Name three labour saving devices?

(3) |

Feeders

Feet Folders |

|

|

What are the benefits of using a feeder?

(3) |

Fast

Accurate Leaves operator's hand free |

|

|

What are folders?

(4) |

Attachments with a groove for folding

waistbands neck bands cuffs |

|

|

What are the benefits of folders?

(2) |

Accurate

Saves manual labour |

|

|

Name three types of feet

(3) |

Hemming feet

Binders Gathering feet |

|

|

What is the purpose of hemming feet?

(1) |

Feet fold hems evenly and neatly.

|

|

|

What widths are hemming feet available in?

(1) |

3mm - 5mm

|

|

|

What size rolled hems are hemming feet able to sew?

(1) |

6mm

|

|

|

What are the benefits of hemming feet?

(2) |

Saves time

Saves labour |

|

|

What do binders do?

(2) |

Fold and

attach bias binding |

|

|

What is another name for gathering feet?

(1) |

Shirring feet

|

|

|

What does a gathering foot do?

(2) |

Retards feeding action

so gathers fabric |

|

|

What are the requirements of work surfaces in the pattern room?

(2) |

Depends on pattern maker's preference

Smooth, flat surfaces for tracing blocks and making markers |

|

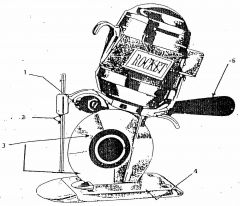

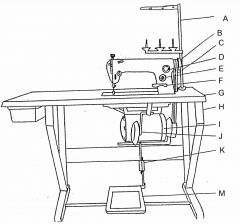

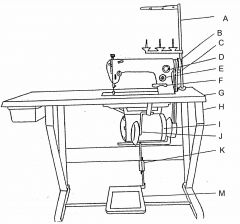

What is this machine?

(1) |

Straight knife / blade

|

|

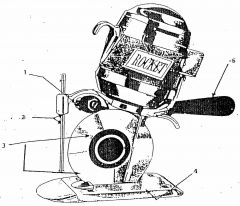

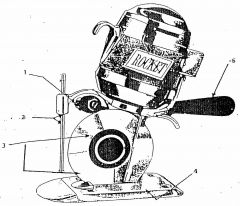

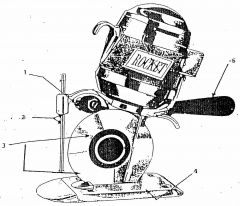

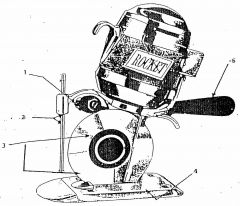

What is this machine?

(1) |

Circular blade / Round knife / Rotary

|

|

What is this machine?

(1) |

Handheld round knife cutter

|

|

What is 1?

(1) |

Differential grinder

|

|

What is 2?

(1) |

Safety shield

|

|

What is 3?

(1) |

Rotary blade

|

|

What is 4?

(1) |

Base plate

|

|

What is 5?

(1) |

Control handle

|

|

What is this machine?

(1) |

Laying up machine

|

|

What is this machine?

(1) |

Cloth drill marker

or hot drill |

|

What is this machine?

(1) |

Thread marker

|

|

What is this machine?

(1) |

Hot notcher

|

|

What is this machine?

(1) |

Pattern perforator

|

|

What is this machine?

(1) |

Ticketing machine

or sober machine |

|

What is this?

(1) |

Adjustable cloth clamp

|

|

What is this?

(1) |

Cloth clamp

|

|

What is this?

(1) |

Reservoir or flash iron

|

|

What is this?

(1) |

Utility press

|

|

What is this?

(1) |

Vacuum table

|

|

What does this symbol indicate on a workflow chart?

(1) |

Process or work activity

|

|

What does this symbol indicate on a workflow chart?

(1) |

Transport: movement of workers; materials or products

|

|

What does this symbol indicate on a workflow chart?

(1) |

Permanent storage

|

|

What does this symbol indicate on a workflow chart?

(2) |

Temporary storage

or delay |

|

What does this symbol indicate on a workflow chart?

(1) |

Inspection

|

|

What does this symbol indicate on a workflow chart?

(2) |

Combined activity

Outside symbol is dominant activity |

|

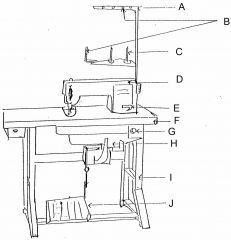

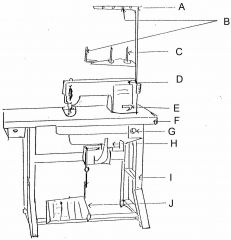

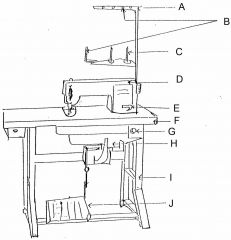

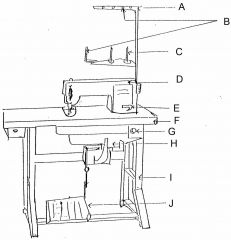

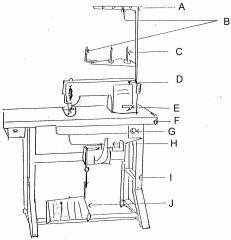

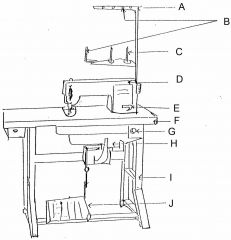

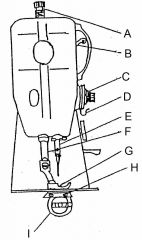

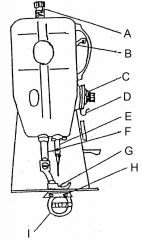

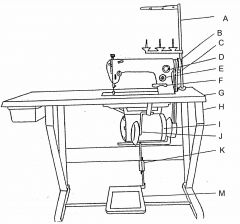

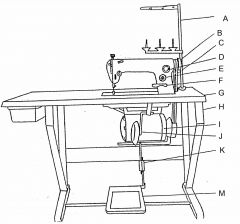

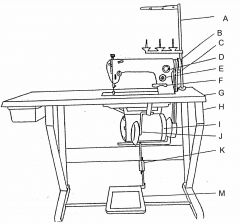

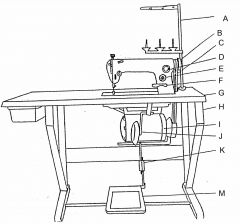

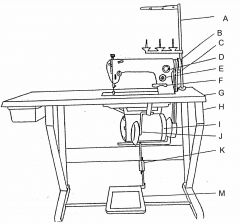

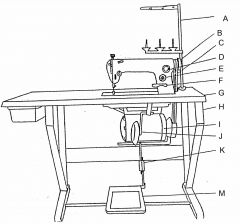

What is this?

(1) |

Industrial lock stitch machine

|

|

What is at A?

(1) |

Thread guide arm

|

|

What is at B?

(1) |

Thread guide

|

|

What is at C?

(1) |

Spool pin

|

|

What is at D?

(1) |

Machine head

|

|

What is at E?

(1) |

Reverse lever

|

|

What is at F?

(1) |

Table top

|

|

What is at G?

(1) |

Switch

|

|

What is at H?

(1) |

Motor

|

|

What is at I?

(1) |

Stand

|

|

What is at J?

(1) |

Foot controller

|

|

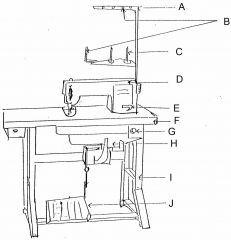

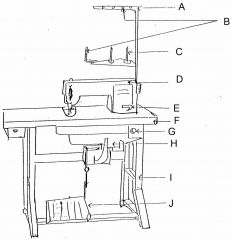

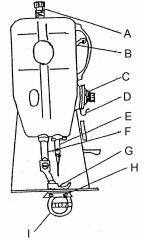

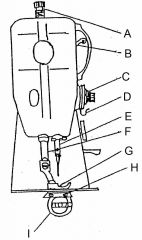

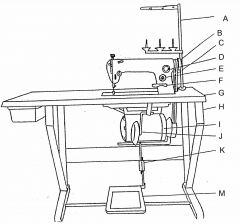

What is at A?

(1) |

Presser bar adjusting scree

|

|

What is at B?

(1) |

Take up lever

|

|

What is at C?

(1) |

Needle thread tension assembly

|

|

What is at D?

(1) |

Check spring / Take up spring

|

|

What is at E?

(1) |

Needle bar and needle

|

|

What is at F?

(1) |

Presser bar

|

|

What is at G?

(1) |

Presser foot

|

|

What is at H?

(1) |

Feed dog

|

|

What is at I?

(1) |

Sewing implement

|

|

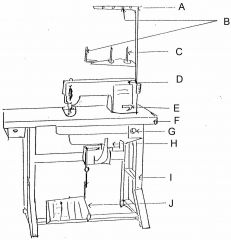

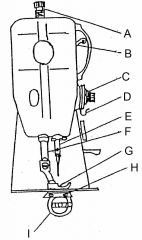

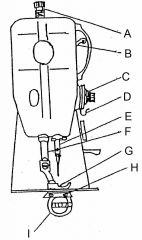

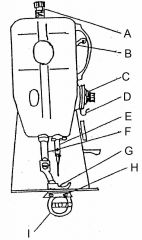

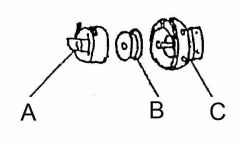

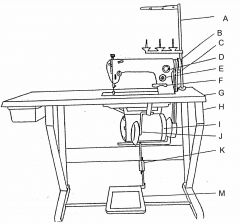

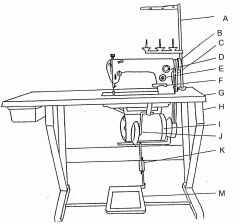

What is at A?

(1) |

Bobbin case

|

|

What is at B?

(1) |

Bobbin

|

|

What is at C?

(1) |

Rotary hook

|

|

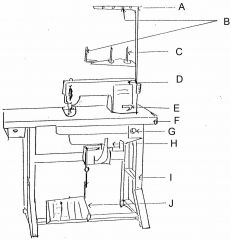

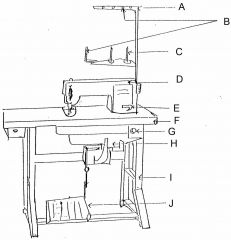

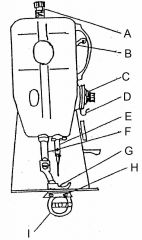

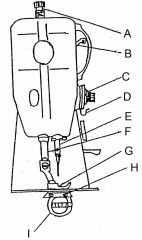

What is at A?

(1) |

Thread stand

|

|

What is at B?

(1) |

Machine handwheel

|

|

What is at C?

(1) |

Vee belt

|

|

What is at D?

(1) |

Oil flow window

|

|

What is at E?

(1) |

Stitch length regulator

|

|

What is at F?

(1) |

Reverse feed lever

|

|

What is at G?

(1) |

Table top

|

|

What is at H?

(1) |

Machine stand

|

|

What is at I?

(1) |

Clutch motor

|

|

What is at J?

(1) |

Knee lifter (machine foot)

|

|

What is at K?

(1) |

Pitman rod

|

|

|

What is at M?

(1) |

Treadle

|

|

What is this?

(1) |

Hemming foot

|

|

What is this?

(1) |

Binder foot

|

|

What is this?

(1) |

Gathering foot

|

|

What is this?

(1) |

Elastic shirring foot

|

|

What is this?

(1) |

Grading machine

|

|

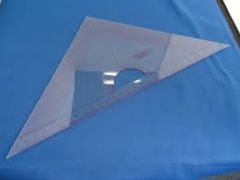

What is this?

(1) |

Perspex tailor's square

|

|

What is this?

(1) |

Needlepoint tracer

|

|

What is this?

(1) |

Pattern hook

|

|

What is this?

(1) |

Pattern punch

|

|

What is this?

(1) |

Pattern notcher

|

|

What is this?

(1) |

Collar turner

|