![]()

![]()

![]()

Use LEFT and RIGHT arrow keys to navigate between flashcards;

Use UP and DOWN arrow keys to flip the card;

H to show hint;

A reads text to speech;

33 Cards in this Set

- Front

- Back

|

Three main ways to identify bottle types |

manufacturing technique bottle bases labelling and embossing |

|

|

1st glass bottles |

Free blown (handmade), only kind of glass bottles until 1730s. gob of hot glass on blow pipe, molded on a marver table, removed with a pontil rod, gets cracked off.

|

|

|

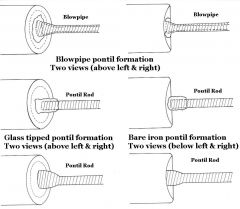

Pontil marks |

From pontil rod that gets glass off blow pipe.

|

|

|

Cracked off finish |

|

|

|

Laid on Ring |

Band of glass put around finish but wasn't worked in any way |

|

|

Applied Finish |

extra glass blob put on and a finishing tool is used (spun) made between 1820s-1920s |

|

|

Dip mold? |

free blown glass, dipped in a bucket to shape it, shoulders usually wider, no seams |

|

|

Tooled Finish |

1820s-1920s free blown glass has neck made extra long and a finishing tool is used on the mouth. Can usually see tool marks |

|

|

two piece mold |

1750s to 1880s for smaller bottles, seams run down sides and along base, could have embossed lettering |

|

|

three piece molds |

1830s to 1920s the brand name was Ricketts 2 shoulders, and base molds could have embossing on shoulders |

|

|

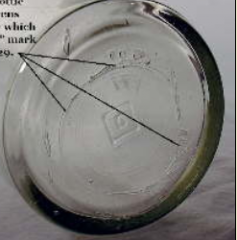

Post bottom |

1850-1930 seams down sides and base with a circular seam in center can emboss |

|

|

Cup bottom |

1850-1930 side seams and along base (not through it) |

|

|

Hutchinson stopper |

1879-1920 wire metal closure with rubber gasket, for pressurizing drinks |

|

|

Lightening closure |

1875-1920 wire neck closure |

|

|

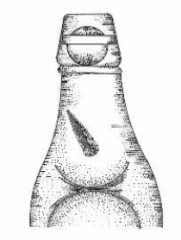

Codd stoppers |

1872-1920 marble stopper popular in India and Japan |

|

|

Turn paste mold |

1870-1920 spin mold, very geometric no mold marks, seams no lettering |

|

|

Mechanization of bottle production? |

1881 multi-part molds (10+ parts) ghost seams from being moved from mold to mold |

|

|

Owen's machine |

1904 first fully automated bottle making does process backwards (finish, body, base) has air suction scars and feathering |

|

|

Crown seal finish |

1892-present |

|

|

solarized glass |

had magnese dioxide colourless until sunlight, then purple 1875-1918 |

|

|

ghost seams from multiple mold, mechanized bottle production (1881) |

|

|

applied finish (1820-1920) |

|

|

Tooled finish (1820-1920) |

|

|

Two piece mold illustration 1750-1880 |

|

|

Lightening closure 1875-1920 |

|

|

Codd stopper 1872-1920 |

|

|

Hutchinson stopper 1879-1920 |

|

|

Dip mold (free blown glass) |

|

|

Three piece mold bottle Rickett brand 1830-1920 |

|

|

Two piece mold 1750-1880 |

|

|

Post bottom 1850-1930 |

|

|

Cup bottom 1850-1930 |

|

|

Owen's scar 1904 fully automated |