![]()

![]()

![]()

Use LEFT and RIGHT arrow keys to navigate between flashcards;

Use UP and DOWN arrow keys to flip the card;

H to show hint;

A reads text to speech;

51 Cards in this Set

- Front

- Back

|

Purpose of Forced Draft Fans? (Secondary Air System) |

To provide preheated air to the boiler windboxes to support the combustion of the fuel oil, main gas and ignitor gas. |

|

|

Purpose of the Induced Draft Fans? (Furnace Pressure Control System) |

To remove the combustion flue gases from the boiler and maintain the furnace at a negative pressure. |

|

|

Purpose of the Gas Recirculation Fans? (Gas Recirculation System) |

To maintain the reheat steam temperature by recirculating hot combustion flue gases back into the boiler. |

|

|

Purpose of the Carbon Reinjection System? |

To return the fly ash particles (in the form of carbon deposits) collected in the precipitator hoppers back into the boiler furnace to be reburned. |

|

|

Purpose of the Precipitators? ( Electrostatic Precipitator system) |

To remove fly ash particles contained in the combustion flue gasses and collect the particles for reinjection back into the boiler. |

|

|

Purpose of the Air Preheaters? (Combustion Air Heater System) |

To preheat the secondary air supplied to the boiler windboxes to increase the combustion efficiency. |

|

|

What are the other systems are supplied by the FD fans? |

• Provides air for the ignitor air booster fan • Provides air to the gas recirculation fan seal air dampers |

|

|

What does SOFA stand for? |

Separated Overfire Air |

|

|

Where does the FD fan discharge to? |

Air discharged from each forced draft fan blows through a manually operated shut off damper into a common ignitor air duct. An ignitor air booster fan takes suction on the common ignitor air duct from the forced draft fans on the 61' elevation. The fan discharges air through a control damper into a common discharge duct which distributes the air to tiers 3, 5, 7, and 9 ignitor windboxes. |

|

|

What is supplied to the FD fan bearings? |

Closed cooling water |

|

|

How many volts is the FD fan? |

4kv |

|

|

What is the purpose of the ignitor air booster fan? |

To increase the air supply to the ignitors. |

|

|

Purpose of fuel air dampers? |

Used to control the amount of air around each burner. |

|

|

Purpose of the Auxiliary Air Dampers? |

Installed above and below each oil gun compartment to control the amount of secondary air being admitted above and below each burner. |

|

|

How do the air heaters work? |

The air heaters are large cylindrical rotating heaters in which rotating elements absorb the heat from the combustion flue gasses and transfer the heat to the secondary air. Combustion flue gasses enter the top of the air heater and flow down through the heating elements. Secondary air enters the bottom of the air heater and flows up through the heating elements. |

|

|

Main Drive Motor |

480 volt motor that turns the air heaters at a constant speed of 1.4 rpm. |

|

|

Backup Air Drive Motor |

Operates the air heater in the event of the main drive motor failing. Operates on compressed air and turns the air heater at a constant speed of 1.4 rpm. A 120 VDC powered solenoid valve installed in the air supply line to the backup air drive motor is energized when the main drive motor trips, supplying air to the back-up air drive motor. |

|

|

Air heater guide bearing |

Has an oil lubrication system located on 101'. The oil system for each guide bearing consists of an oil pump and a fan cold oil cooler. The oil pump is driven by 480 V electric motor. |

|

|

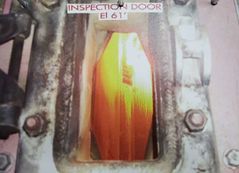

Wash Water Motor |

Turns the air heater at a slower speed to ensure proper cleaning of the heating surfaces. Awash motor for each air heater is located on the 61 elevation. The motor is controlled by a local off/on switch located on the same elevation. Each wash motor is a 480 V electric motor. |

|

|

Seal air dampers |

Prevents a back flow of furnace gasses through the recirculating gas ducts and maintains the fans in a warmed up condition, when the fans are not operating. |

|

|

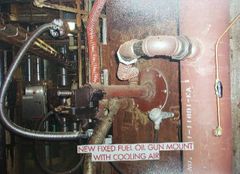

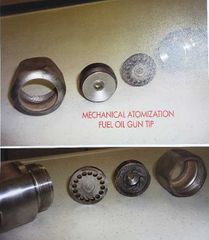

Purpose of the No. 6 Furl Oil System? |

To receive No. 6 fuel oil from the Fuel Oil Unloading, Transfer, and Storage System, and to provide the fuel oil to the oil guns at the appropriate temperature, pressure, and viscosity for proper mechanical atomization and co.plete combustion in the furnace. |

|

|

Purpose of the Purge Steam System? |

To purge the fuel oil guns of No. 6 fuel oil whenever a fuel gun is removed from service. Purging the guns with steam prevents the fuel oil from plugging in the guns and blocking the tips. |

|

|

How many fuel oil burner pumps must be in operation at full unit load? |

Two |

|

|

The high pressure fuel oil heaters are designed to increase the fuel oil temperature to what temperature? |

Increases fuel oil temperature from 130°F to 260°F. |

|

|

The fuel oil day tank is designed to supply fuel oil to the fuel oil guns for how many hours at full unit load? |

32 hours |

|

|

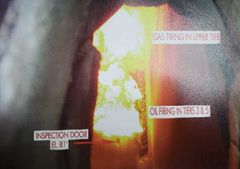

What burners are used to warm up the boiler during an initial start up? |

Gas burners |

|

|

On what tiers are the retractable fuel oil guns located? |

3, 5, 7, and 9 |

|

|

The No. 6 fuel oil system consists of? |

1. Fuel oil day tank 2. Fuel oil burner pumps 3. Fuel oil burner pumps recirculation pressure control valve 4. High pressure fuel oil heaters 5. Fuel oil meters 6. Fuel oil trip valve & trips 7. Fuel oil control valve 8. Fuel oil hydrometer valves 9. Motor-operated recirculation valve |

|

|

The fuel oil heater drips system is considered a part of what system? |

Auxiliary steam system |

|

|

The fuel oil heater drip system consists of?s |

The heater drip pots, the heater drips level tank and the strainer drain pump. |

|

|

. |

|

|

. |

|

|

. |

|

|

. |

|

|

. |

|

|

. |

|

|

. |

|

|

. |

|

|

. |

|

|

. |

|

|

. |

|

|

. |

|

|

. |

|

|

How do you remove a fuel oil gun? |

|

|

|

Purpose of the fuel air dampers |

Controls the flow of combustion air around the burners for better mixing of fuel for combustion. Located to direct air flow behind burners, enclosed in the wind box |

|

|

Purpose of the auxiliary air dampers |

To supply necessary supplementary air requirements and maintain a fixed wind box to furnace differential for proper fitting conditions. Located to direct air file above and below fuel compartments, enclosed in the wind box. |

|

|

Purpose of the burner tilts |

To quickly and effectively change the superheater temperature |

|

|

Prepare of the soot blower system |

To keep the external heating surfaces clean to facilitate maintaining reheat and superheat steam temperatures within the desired operating range of the unit. |

|

|

Proper od the gsd recirculating fans |

To redirect a portion of the flue gases leaving the economizer back to the furnace to help maintain reheat steam temperatures. |

|

|

Purpose of the precipitators |

To remove ash particles from the flue gas |

|

|

Prosser of the ID fans |

To aid in the removal of flue gases from the boiler and maintain a negative pressure inside the boiler |