![]()

![]()

![]()

Use LEFT and RIGHT arrow keys to navigate between flashcards;

Use UP and DOWN arrow keys to flip the card;

H to show hint;

A reads text to speech;

14 Cards in this Set

- Front

- Back

|

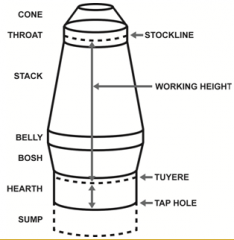

Draw Typical Blast Furnace Profile |

|

|

|

What are the two types of water cooling elements in blast furnace cooling systems |

1. Copper cooling plates 2.Staves of either cast iron(for cooler upper parts) and copper (for hotter lower parts) |

|

|

Types of Hot blast stoves |

-internal combustion chamber (most common in NA) -external combustion chamber >davy krupp koppers >didier M&P -Kalugin Stove |

|

|

Slag Processing: What is it, what is it made off and what are the main processes? |

1. Valuable by-product from ironmaking 2 Asphalt aggregate (common in Canada), concrete aggregate, mineral wool, clinker substitute in Portland cement. 3. Main processes: -slag granulation with water -slag pelletization with water (common in Canada) -slag pit process |

|

|

Describe slag granulation and slag pelletization |

1. slag granulation is the pouring of molten slag through high-pressure water spray. transported to filtering and dewatering systems. common in EU, is an INBA process 2.Molten slag is poured onto plate, which deflects it, sheet of slag is sheared by controlled water jets. slag swells and cools. it is then projected centrifugally on rotatin drum for final blwoing and cooling. used in road aggregate |

|

|

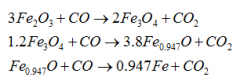

Describe the reduction of iron oxides and what are the chemical formulas of each. |

sequential reduction of hematite to magneitie to wustite and finally iron. 1.hematite: Fe2O3 2. magnetite: Fe3O4 3. wustite: FeO |

|

|

What can you interpret on the ellingham diagram? |

A given metal can reduce the oxides of all other metals whose lines lie above theirs on thediagram. For example, the 2Mg + O2 ==> 2MgO line lies below the Ti + O2 ==> TiO2 line, andso magnesium can reduce titanium oxide to metallic titanium |

|

|

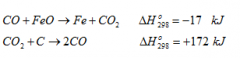

What is the Boudouard reaction? |

CO2+C --> 2CO Very endothermic and has a high activation energy. Essentially stops below 1200K |

|

|

In what ways is wustite reduction rate-limiting? |

1. Strength of gas required 2. Volume of gas required -If 1 mole of Fe is made, then 1 mole of CO2 is made, and by the Boudouardreaction, 2 moles of CO are produced 2 moles of CO reduces 7.6 moles of FeO fromFe3O4 |

|

|

What is raceway and what is the reaction that occurs? |

1. hurtling coke particles. Tuyere pressure and flow push coke away from the tuyeres to form a raceway. 2. oxygen gas reactions with carbon to form CO2 but encounters more coke for bouduard reaction to occur |

|

|

Why is the blast furnace shaped like it is? |

1. Inverted u-shape for support and for gas distribution. 2. coke slits have less resistance to gas flow |

|

|

What are the cohesive zone reactions? |

|

|

|

What happens in the cohesive zone? what is thermal and chemical reserve zone and what reaction is it driven by? |

1. temperature drops rapidly in cohesive zone until bouduard reaction stops. 2. thermal reserve zone: zone of relatively constant temperature that can enlarge or decrease 3. chemical reserve zone: gas composition is set at 70/30 which is enough for hematite and magnetite reduction 4. thermal and chemical zone is driven by wustite reaction |

|

|

Describe the gases in stack ( what happens in upper part of furnace, top gas composition and residence times) |

-In the upper part of the furnaces, the higheroxides are reduced, moisture evaporated and gases cool -Top gas composition: >21 – 21% CO >20 – 22%CO2 -Residence times: >Gas: ~ 1 second >Solids: 5 – 8 hours |