![]()

![]()

![]()

Use LEFT and RIGHT arrow keys to navigate between flashcards;

Use UP and DOWN arrow keys to flip the card;

H to show hint;

A reads text to speech;

34 Cards in this Set

- Front

- Back

|

Project Quality Mgmt knowledge area |

includes the processes and activities of the performing organization that determine quality policies, objectives, and responsibilities so that the project will satisfy the needs for which it was undertaken. |

|

|

Plan Quality Mgmt process |

ID's quality requirements and/or standards for the project and its deliverables and documenting how the project will demonstrate compliance with quality requirements and/or standards. |

|

|

Quality as per ISO 9000 [10] |

the degree to which a set of inherent characteristics fulfill requirements. |

|

|

Aspects important to Quality |

1. Customer Satisfaction 2. Prevention over Inspection 3. Continuous Improvement 4. Mgmt Responsibility 5. COQ |

|

|

Continuous Improvement methods |

1. Plan-Do-Check-Act (PDCA) cycle 2. Total Quality Mgmt (TQM) 3. Six Sigma 4. Lean Six Sigma |

|

|

Commonly used process improvement models |

1. Malcolm Bridge 2. Organizational PM Maturity Model (OPM3) 3. Capability Maturity Model Integration (CMMI) |

|

|

Cost of Quality (COQ) |

refers to the total cost of the conformance work and the non-conformance work that should be done as a compensatory effort. |

|

|

COQ: Cost of Conformance categories |

1. Prevention Cost 2. Appraisal Cost |

|

|

COG: Cost of Conformance: Appraisal Costs |

1. Testing 2. Destructive testing loss 3. Inspections |

|

|

COG: Cost of Conformance: Prevention Cost |

1. Training 2. Document Processes 3. Equipment 4. Time to do it Right |

|

|

COG: Cost of Non-conformance |

1. Internal Failure 2. External Failure |

|

|

COG: Cost of Non-conformance: Internal |

1. Rework 2. Scrap |

|

|

COG: Cost of Non-conformance: External |

1. Liabilities 2. Warranty Work 3. Lost Business |

|

|

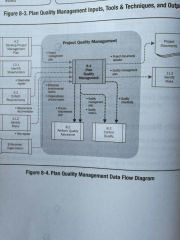

Plan Quality Mgmt process inputs |

1. PM Plan 2. Stakeholder Register 3. Risk Register 4. Requirements Documentation 5. EEF 6. OPA |

|

|

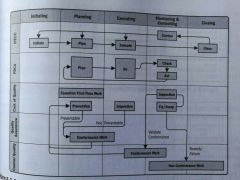

Relationships between QA and CQ to the COQ, PDCA, and IPECC models and PM process groups |

|

|

|

Plan Quality Mgmt Data Flow Diagram |

|

|

|

What aspects of the PM Plan act as inputs for the Plan Quality Mgmt process? |

1. Scope Baseline 2. Schedule Baseline 3. Cost Baseline 4. Other Plans |

|

|

Plan Quality Mgmt process T&T's |

1. Cost-Benefit Analysis (CBA) 2. COQ 3. Seven Basic Quality Tools 4. Benchmarking 5. Design of Experiments 6. Statistical Sampling 7. Additional Quality Planning Tools 8. Meetings |

|

|

Seven Basic Quality Tools |

1. Cause-and-Effect diagrams (fishbones) 2. Flowcharts 3. Checksheets 4. Pareto diagrams 5. Histograms 6. Control Charts 7. Scatter diagrams |

|

|

Fishbone diagram |

problem is placed at the head and traces the problem back to the root cause. Often proves useful in linking undesirable effects seen as special variation. |

|

|

Checksheets |

are used to organize facts in a manner that will facilitate the effective collection of useful data about a potential quality problem. Especially useful for gathering attributes data while performing inspections to ID defects. |

|

|

Pareto diagrams |

Vertical bar charts used to ID the vital few sources that are responsible for causing most of a problem's effects. |

|

|

Histograms |

bar charts that describe the central tendency, dispersion, and shape of a statistical distribution. Does NOT factor time. |

|

|

Control Charts |

determines if a process is stable or has a predictable performance. An upper and lower control limit is set and the process must perform within that range. |

|

|

When evaluating a process via a control chart when is a process determined to be out of control? |

1. A data point exceeds a control limit 2. Seven consecutive plot points above or below the mean |

|

|

Design of Experiments (DOE) |

is a statistical method for IDing which factors may influence specific variables of a product or process under development or production. May be used during Plan Quality Mgmt process to determine the # and type of tests and their impact on COQ. |

|

|

DOE also |

plays a role in optimizing products or processes |

|

|

Additional Quality Planning Tools are |

1. Brainstorming 2. Force Field Analysis 3. Nominal Group Technique 4. Quality Mgmt and Control Tools (discussed in 8.2) |

|

|

Plan Quality Mgmt process outputs |

1. Quality Mgmt Plan 2. Process Improvement Plan 3. Quality Metrics 4. Quality Checklists 5. Project Document Updates |

|

|

Quality Mgmt Plan |

a component of the PM Plan that describes how the organization's quality policies will be implemented. |

|

|

Process Improvement Plan |

a subsidiary of the PM Plan that details the steps for analyzing PM and product development processes to identify activities that enhance their value. |

|

|

Areas to consider in the Process Improvement Plan |

1. Process Boundaries 2. Process Configuration 3. Process Metrics 4. Targets for Improved Performance |

|

|

Examples of Quality Metrics |

1. On-Time Performance 2. Cost Control 3. Defect Frequency 4. Failure Rate 5. Availability 6. Reliability 7. Test Coverage |

|

|

Quality Mgmt Plan generally contains |

Section A: Quality Control 1. Major Deliverable to be Tested 2. Standards and Criteria 3. Monitoring and Controlling 4. Quality Control Schedule Section B: Quality Assurance 1. Processes subject to QA 2. Standards and Stakeholder Expectations 3. QA Activities 4. QA Schedule Section C: Continuous Process Improvement |