![]()

![]()

![]()

Use LEFT and RIGHT arrow keys to navigate between flashcards;

Use UP and DOWN arrow keys to flip the card;

H to show hint;

A reads text to speech;

17 Cards in this Set

- Front

- Back

Label the parts of a tree and their primary functions |

Crown: Photosynthesis, develops sap Trunk: Supports crown, pathway of nutrients Roots: Collects nutrients and moisture, support system for tree |

|

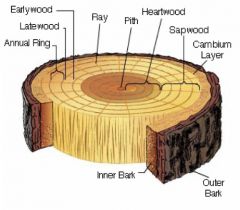

Label the parts of a trunk cross section |

Pith Heartwood Sapwood Cambium layer Bast Bark |

|

|

What form of tree does softwood come from? |

coniferous (seeds are not protected and have needles rather than leaves) |

|

|

What form of tree does hardwood come from? |

most often deciduous trees that are angiosperms (broad leaves rather than needles and do not have resin) |

|

What type of milling is this? |

Quarter sawn |

|

What type of milling is this? |

Flat/plain sawn |

|

|

How do flat sawn and quarter sawn timber differ as they season? |

Flat sawn timber cups away from the pith as it seasons. Quarter sawn timber is more dimensionally stable as it seasons (it swells rather than cups). |

|

|

What is seasoning of timber? |

Reducing the amount of moisture in wood to a stable state |

|

|

Describe green timber |

Fresh cut timber: Up to 90% moisture content, water kept as free water inside the cells, bound water is trapped within cell walls |

|

|

Describe air dried timber |

About 12-20% moisture content: Requires one year of drying per inch of timber thickness, best for steam bending, placing evenly spaced and same thickness gluts between timber reduces warping |

|

|

Describe kiln dried timber |

About 6-10% moisture content: Dried in an oven (manipulation of moisture levels, temperature, and air flow), can be more stressful on timber |

|

Describe this timber distortion |

Twist: Angular rotation around the longitudinal axis (most difficult distortion to correct) |

|

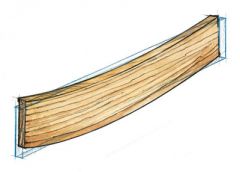

Describe this timber distortion and the best way to correct it |

Cup: End distortion, reduce on the jointer, cut in half along the band saw to reduce cup if severe |

|

Describe this timber distortion and the best way to correct it |

Crook: Edge distortion, saw edges even on the band saw (easiest correction) |

|

Describe this timber distortion and the best way to correct it |

Bow: Face distortion, cut broad down to conserve wood |

|

|

What is the shortest board that can safely be put through the thicknesser? |

350-400mm |

|

|

What is short grain and what are the disadvantages? |

Where the length of the grain is shorter than the width of the board, which makes the board very weak |