![]()

![]()

![]()

Use LEFT and RIGHT arrow keys to navigate between flashcards;

Use UP and DOWN arrow keys to flip the card;

H to show hint;

A reads text to speech;

66 Cards in this Set

- Front

- Back

|

Structural shapes formed by |

Hot rolling |

|

|

Standard views used to illustrate steel structures on drawings |

Plan view, elevation view, section views |

|

|

View looking down on top of structure, multi story building require more views |

Plan view |

|

|

Looking from one side of building. Shows vertical height dimensions |

Elevation view |

|

|

Gives close up detail of part or section of building |

Section views |

|

|

Used to show location of holes, clips, base plates |

Detail drawings |

|

|

Shape for misc. |

M |

|

|

W columns have |

Equal web and flange thicknesses |

|

|

W beams have |

Unequal web and flange thicknesses |

|

|

ST, WT and MT structural tees made by |

Cutting S, W or M shape beams or columns in half |

|

|

Beam/Column designation for W12x20x2 |

W shape with nominal depth of 12 ", weight is 20 lb/ft, piece is 2 feet long |

|

|

Bolt holes on structural members laid out on |

Gage lines |

|

|

Gauge line is |

The distance from the line to the heel of an angle or channel or the centerline of a beam web |

|

|

Holes are spaced in what direction |

Parallel to the length of the member |

|

|

Hole spacing on the gage line |

Pitch |

|

|

3 methods of showing dimensions on a print |

Standard, extension, group |

|

|

Most difficult method of dimensions to read on print |

Group |

|

|

Easiest dimension method to use on drawings |

Extension |

|

|

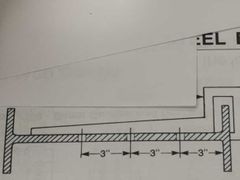

Group dimension |

|

|

Extension |

|

|

Standard |

|

|

Drawing shows dimensions from hole to hole |

Group |

|

|

Size of heavy hex head on bolt specified to be |

Same as nut |

|

|

Bolt type has shorter thread length to eliminate it from the shear plane |

Structural bolts |

|

|

Snug tight condition |

When all plies of joint are in firm contact |

|

|

Slip critical connection (friction type connection) definition |

Relies on friction between steel plies and high clamp load of structural bolt and nut to prevent movement |

|

|

Connection requires specific torque for given bolt size |

Slip critical connections |

|

|

2 types of bolting methods |

Slip critical and snug tight |

|

|

4 methods of fully tensioning bolts for slip connections |

Turn the nut method, alternative bolts, head indicating washer (DTI), calibrated torque wrench |

|

|

Least favorable of the 4 methods of tightening bolts |

Torque wrench |

|

|

Body of bolt |

Distance from under the head to End of bolt |

|

|

Specific load that a fastener must be tested at without any indication of deformation or failure |

Proof load |

|

|

Larger edge distance required when |

Hole is near sheared edge |

|

|

Steel base plates required when |

Columns bear on concrete footings |

|

|

Sufficient number of anchor bolts to hold verticle columns in base plates |

2 |

|

|

Thickness of base plate should be no less than |

1/5 x the overhang from the column to base plate edge |

|

|

Anchor rods made from what material |

ASTM A36 |

|

|

Seated beam shear designed to support what kind of load |

Vertical only |

|

|

Seated beam shear most commonly used |

At beam to column supports |

|

|

Stiffened thickness must not be less than |

Beam web thickness |

|

|

Min. And max end plate thickness |

6mm min 10 mm max |

|

|

End plate thickness based on |

Minimum edge distance |

|

|

Minimum angle thickness |

6mm |

|

|

Shear connections are for |

Vertical shearing |

|

|

Minimum and maximum clearance between beam and column |

10-20 mm |

|

|

Vertical support members In a structural steel frame |

Columns |

|

|

Horizontal support members inna structural steel frame building. Usually made from wide flange shapes |

Beams |

|

|

Horizontal support members in structural frame used to span between columns in building or between supports in a bridge |

Girders |

|

|

Built up shapes that support roofs and floor systems. Used in place of girders when long spans desired but overall weight is a consideration |

Trusses |

|

|

The thickness of material or parts which the fastener is design to secure when fully assembled |

The Grip |

|

|

Bolt body length is from |

Underside of the head to the last scratch of thread |

|

|

Bolt length |

Length from underside of the head to the extreme end of the bolt |

|

|

Test load which a fastener must withstand without any indication of significant deformation or failure |

Proof load |

|

|

Thread length of a bolt |

From the extreme point of the bolt to the last complete thread |

|

|

Circular boss on the bearing surface of a bolt or nut |

Washer face |

|

|

Shop bolt |

|

|

Countersink near side |

|

|

Countersink far side |

|

|

Open holes |

|

|

Field splice |

|

What tool is being used on the beam |

Beam web gauge |

|

|

% of holes in all the joints must have hand tightened bolts or drift pins in place before removing crane |

50% |

|

|

Is dry packing grout acceptable in bearing areas? |

No |

|

|

What is the type of grout used for bearing areas |

Sika 212 flowable grout |

|

|

CSA standard for structural welded steel construction |

W59 |

|

|

CSA standard for welding of steel structures |

W47.1 |