![]()

![]()

![]()

Use LEFT and RIGHT arrow keys to navigate between flashcards;

Use UP and DOWN arrow keys to flip the card;

H to show hint;

A reads text to speech;

72 Cards in this Set

- Front

- Back

|

voltage |

the difference in potentials between two point |

|

|

current |

the movement or flow of electric charges |

|

|

resistance |

the property of material which opposes the flow of electric current |

|

|

ohms law |

the current flowing in a circuit is directly proportional to the voltage & inversely proportional to the resistance. |

|

|

e= r*i |

ohms law |

|

|

conductor |

permits electrons or electric current to flow through it |

|

|

conductors |

have low resistance to electricity |

|

|

insulator |

used to provide barrier around a conductor |

|

|

semiconductors |

can change their resistance to acts as either a conductor or an insulator |

|

|

electric circuit |

may take multiple paths flowing through all possible circuits |

|

|

equipment grounding |

connects all conductive materials that enclose electric lines |

|

|

electrical system grounding |

protects circuits from voltages that may come from lightning or line upsurges |

|

|

bypassing grounds |

can result in electrical fires and fatal accidents |

|

|

cpd- circuit protection device |

protects againts circuit malfunction by preventing too much current from passing from power source to the rest of the circuit |

|

|

GFCI - ground fault circuit Interrupters |

a supersensitive , rapid action power switch which breaks a circyit when there is more than 5ma |

|

|

melting, tripping or opening the break circuit |

gfci will stop the electric flow by |

|

|

lock out |

blocking the flow of energy from the power source to the equipment |

|

|

loto |

protects you from unexpected start up of machines or release of stored energy during service or maintenance |

|

|

lock out |

place a lock on a disconnected switch to make sure it is not removed from its off position |

|

|

tag out |

attach a warning sign where the equipment will be energized |

|

|

authorized employee |

a person who loto the machine |

|

|

affected employee |

employee whose work involves use or operation of equipment |

|

|

loto safeguards |

are designed to protect workers |

|

|

shock |

the passage of electric current through your body |

|

|

electricity |

a silent visible force that can kill without warning if its dangers are ignored |

|

|

1. basic principles of electric safety 2. safe work practices 3. correct response to emergencies |

our safety depends on understanding 3 things |

|

|

1. fuses 2. circuit breakers 3. gfci |

circuit protection device |

|

|

resetting circuit protection device |

|

|

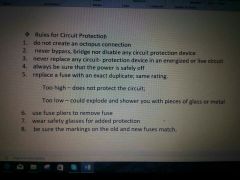

rules for circuit protection |

|

|

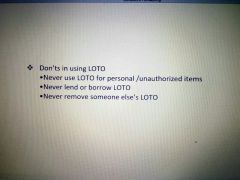

donts in using loto |

|

|

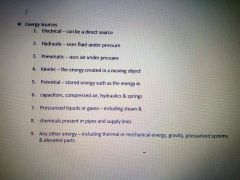

energy sources |

|

|

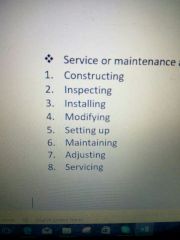

service or maintenance activities on equipment include |

|

|

preparation shutdown isolation application control verify |

6 steps to loto |

|

|

preparation |

know the equipment & its energy source before working on it |

|

|

shutdown |

turn off the equipment |

|

|

isolation |

find and isolate every form of energy that the machines use |

|

|

application |

anything that might restore the flow of energy must be locked out |

|

|

lock box |

places all keys of all employees |

|

|

control |

control stored energy |

|

|

verify |

check and double check |

|

|

3 steps to removal and re energizing |

1. restore work area 2. notify personnel 3. remove loto devices |

|

|

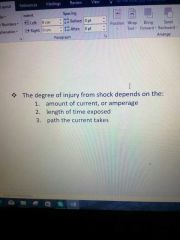

degree of injury of shock depends on the |

|

|

1. mild shock 2. severe shock 3. deadly shock |

electrical emergencies |

|

|

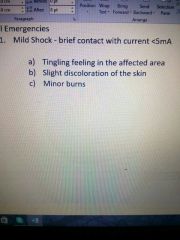

mild shock |

brief contact with less than 5 ma current |

|

|

effectsnof mild shock |

|

|

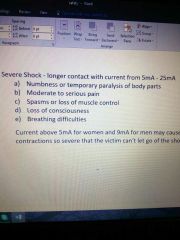

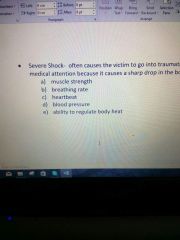

severe shock |

longer current contact from 5ma -25 ma |

|

|

effects of severe shock |

|

|

deadly shock |

happens when a workes is frozen to a electrical contact point grealter than 25 ma |

|

|

effects of deadly shock |

|

|

first aid procedures for mild shock |

|

|

first aid procedures for continous shock |

|

|

first aid procedure for severe shock |

|

|

mechanical hazards |

the exposure to moving parts wheter automatic or manually operated |

|

|

points of operation power transmission in running nip points shear points other moving parts |

moving parts are as follows |

|

|

points of operation |

actual work is performed on the material |

|

|

power transmission points |

where energy or motion is transferred from source to destination |

|

|

nip points |

two or more components running in opposite directions come in contact with each other |

|

|

shear points |

where one moving component of a machine runs past one which is stationary |

|

|

machine guards and safeguards |

these are components that protect the worker from direct contact eoth mechanical hazardw |

|

|

guards |

static protective device that prevent Access to moving parts |

|

|

barriers, fences, enclosures |

example of guards |

|

|

safe guards |

dynamic protective device |

|

|

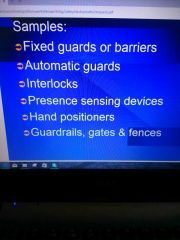

sample of safeguards |

|

|

1. check each guard and safeguard to see if it is in place and operating correctly 2. inspect each guard for signs of abuse l, tampering or damage that could affect its performance 3. test each alarm, warning indicator or emergency system 4. check to see that permanent guards are in place and in good condition 5. examine the ventilation holes or hatches in guards. should be dirt free and not at risk of overheating 6. for moving mechanical parts check presence of appropriate signage |

inspecting for mechanical hazards |

|

|

Fixed Interlocked Adjustable Self-Adjusting |

4 types of guards |

|

|

fatalities

|

employeesgetting caught in rotating shafts such as well boring drills & lathes |

|

|

fixed guards |

•Apermanent part of the machine•Notdependent on any other part to perform the function•Usuallymade of sheet metal, screen, bars or other material which will withstand theanticipated impact•Generallyconsidered the preferred type of guard.•Simpleand durable |

|

|

interlockedGuard |

•Usuallyconnected to a mechanism that will cut off the power automatically•Coulduse electrical, mechanical or hydraulic systems•Shouldrely on a manual reset system |

|

|

nAdjustableGuard |

•Veryflexible to accommodate various types of stock.•Manuallyadjusted |

|

|

self-Adjusting> |

•Theopening is determined by the movement of the stock through the guard.Doesnot always provide maximum protection |

|

|

BenchGrinders |

requirea work rest with a maximum clearance of 1/8 inch to insure that the work doesnot get drawn into the grinding wheel. |

|

|

push stick |

cankeep your fingers on the end of your hands!! |