![]()

![]()

![]()

Use LEFT and RIGHT arrow keys to navigate between flashcards;

Use UP and DOWN arrow keys to flip the card;

H to show hint;

A reads text to speech;

44 Cards in this Set

- Front

- Back

|

What does GMAW stand for? |

Gas Metal Arc Welding |

|

|

MIG, Microwire, and CO2 welding are slang for what welding process? |

GMAW |

|

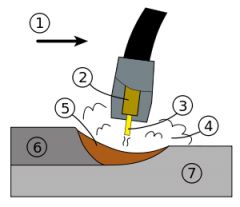

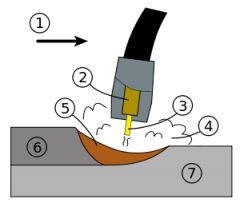

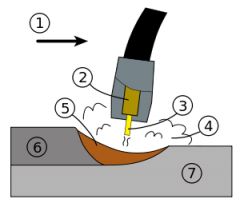

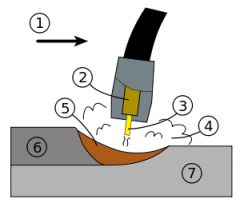

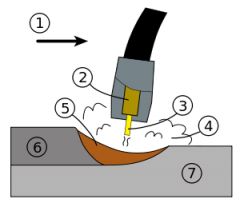

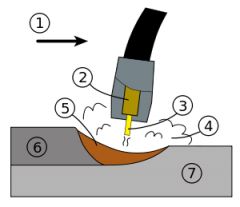

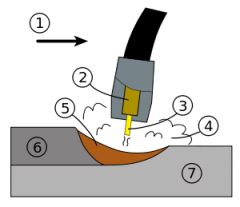

What is #1? |

The nozzel. |

|

What is #2? |

The guide tube |

|

What is #3 |

The electrode |

|

What is #4? |

The shielding gas |

|

What is #5? |

molten weld metal |

|

What is #6? |

solidified weld metal |

|

What is #7? |

The base metal |

|

|

What should you do if there is too much spatter? |

Reduce the voltage |

|

|

What is a sign of too low a voltage? |

Weld is too narrow, no penetration. |

|

|

What is a good stickout distance? |

1/4"-3/8" |

|

|

What is the correct work angle? |

90 degrees |

|

|

What is the correct travel angle? |

15 degrees |

|

|

what are the three types of GMAW application? |

manual, fixed/mechanized, automatic/robotic |

|

|

11 advantages of GMAW |

- it is the only process that can be used on most commercial metals and alloys - little spatter - continuous wire feed means little time spent changing electrodes - it can be used in all positions - the arc and weld pool are visible - little or no slag is produced - he relatively small diameter electrode allows for higher current densities - a high percentage of filler metal ends up in the weld - travel speed and deposit rates are faster than SMAW - light weight power sources can be carried to work - when using spray transfer, deeper penetration is possible compared with SMAW |

|

|

4 limitations of GMAW |

- complex, costly equipment - no wind - larger welding gun must be closer to the work for the shielding gas to work - hot and large arc |

|

|

Does GMAW require constant voltage or constant current? |

trick question: either, though constant voltage is often prefered. |

|

|

what is the purpose of the fixed voltage slope? |

to reduce short circuiting. |

|

|

steeper volt/amp curves lower what two things? |

pinch force and short-circuit current |

|

|

high short-circuit and pinch forces caused by a flat volt/amp slope causes what? |

spatter |

|

|

a very low short circuit current and pinch force caused by a steep volt/amp slope cause what? |

The electrode wire to freeze in the puddle. |

|

|

define pinch force |

the force that causes the molten drop of electrode to seperate from the solid wire electrode. |

|

|

in what system would you use a voltage sensing wire feeder? |

constant current |

|

|

how are wire feed speed and supplied current linked? |

conjunctly (both go up/down with the other) |

|

|

in which power system does the wire feed at a fixed speed? |

constant voltage |

|

|

four modes of GMAW |

short-circuit, spray, globular, and pulsed |

|

|

Which mode produces the least spatter? |

spray transfer |

|

|

what force is used in globular transfer to detach the molten electrode from the end of the solid wire? |

gravity |

|

|

"a short circuit creates a rise in current until the molten globule is pinched off" describes what welding mode? |

short circuit |

|

|

the arc is extinguished and reignited constantly in what welding mode? |

short-circuit |

|

|

which welding modes work well for lover voltages? |

short-circuit and globular |

|

|

why can't one use globular welding out of position or overhead? |

the globule will fall away from the piece or into the gun |

|

|

how stable is the arc in globular? |

not very stable |

|

|

in which mode are the molten globules smaller in diameter than the electrode? |

spray transfer |

|

|

in which mode are the molten globules larger in diameter than the electrode? |

globular |

|

|

which welding mode uses two simultaneous currents, one to maintain the arc, and the other in bursts that melt off the filler? |

Pulse |

|

|

most common power source voltages for welding |

200, 230, 460, or 575 volt |

|

|

what does a duty cycle of 60% indicate? |

the machine can weld 6 out of every 10 minutes. |

|

|

what is duty cycle? |

the percentage of time that a power supply welding machine can operate constantly |

|

|

what kind of current does most GMAW use? |

steady direct current |

|

|

what are the two ways current can be connected? |

electrode positive (reverse polarity) and electrode negative (straight polarity) |

|

|

what is the practical difference between straight and reverse polarity? |

reverse provides more penetration |

|

|

what is the more common type of polarity used in GMAW? |

reverse polarity |