![]()

![]()

![]()

Use LEFT and RIGHT arrow keys to navigate between flashcards;

Use UP and DOWN arrow keys to flip the card;

H to show hint;

A reads text to speech;

44 Cards in this Set

- Front

- Back

|

Maintenance |

All action taken to retain material in a serviceable condition or to restore it to serviceability. It includes inspection, testing, servicing classification as to serviceability, repair, rebuilding, and reclamation. - All supply and repair action taken to keep a force in condition to carry out its mission. - The routine recurring work required to keep a facility (plant, building, structure, ground facility, utility system, or other real property) in such condition that it may be continuously utilized, at its original or designed capacity and efficiency, for its intended purpose. |

|

|

Cannibalization |

- The removal of serviceable parts from an unserviceable item of equipment and installing it on another unserviceable item to make it serviceable. - No documentation. |

|

|

Selective interchange |

The exchange of selected serviceable parts/components from a deadlined item of equipment for unserviceable repair parts/components from a like item. |

|

|

3 Categories of Maintenance |

1. Organizational 2. Intermediate 3. Depot |

|

|

First Echelon Maintenance |

Applies to preventative maintenance. Is performed by the user or equipment operator. This maintenance includes the proper care, use, operation, cleaning, preservation, lubrication, adjustment, minor repair, testing, and parts replacement prescribed by appropriate technical publications. |

|

|

Second Echelon Maintenance |

Applies to corrective maintenance. Includes the performance of scheduled maintenance, diagnosis and isolation of previously identified and traced equipment malfunctions, replacement of major assemblies/modular components that can be readily removed/installed and do not require critical adjustment, and replacement of easily accessible piece parts not authorized at first echelon. |

|

|

Maintenance Battalion |

provides intermediate (third and fourth echelon) maintenance for Marine Corps-furnished tactical ground equipment of a MEF. |

|

|

Electronics maintenance company |

Main emphasis is the repair of secondary reparables and their subsequent return to float stockage. |

|

|

Secondary reparable item |

An item that can be reconditioned or economically repaired for reuse when it becomes unserviceable. Rapid exchange. |

|

|

Replacement and Evacuation program |

Type of float maintained at the depot maintenance level to replace and repair worn out, selected major end items on a regularly scheduled basis. |

|

|

Recoverable items program (RIP/WIR) |

Provides for the recovering, reporting, and managing of equipment that cannot be repaired within the resources of the field commander and for the disposal of items that are beyond economical repair. |

|

|

The capstone publication for policy statements issued by the CMC. |

The Marine Corps Manual. |

|

|

MCO 4790.2C, MIMMS Field Procedures Manual |

Provides MAGTF units with a comprehensive guide for the standardized management of ground equipment maintenance. |

|

|

TM 4700-15/1, Ground Equipment Record Procedures |

Establishes uniform recordkeeping procedures to record and account for maintenance performed on ground equipment. |

|

|

Equipment Technical Manuals |

Provides instructions for the performance of authorized maintenance on specific equipment for each category of maintenance. |

|

|

Marine Corps Stock Lists |

Provides all levels of Marine Corps supply and maintenance operations with essential information for Marine Corps-managed items. |

|

|

8 Functional areas of maintenance management |

1. Maintenance administration 2. Personnel and training 3. Records and reports 4. Publications control 5. Equipment availability 6. Preventative Maintenance Checks and Services and Corrective Maintenance (PMCS) 7. Supply support 8. Maintenance related programs |

|

|

2841 Ground radio maintenance (E1-5), and 2847 Wire/Data maintenance (E1-5) |

Organizational and intermediate level maintenance. |

|

|

2862 Ground Comm Electronics Maintenance Supervisor (E6-7) |

Performing advanced corrective maintenance of any comm electronics equipment.

|

|

|

2891 Ground Comm Electronics Maintenance Chief (E8-9) |

Regimental comm shop or higher. Enlisted duty expert on all ground comm maintenance matters, to include manning and equipping a maintenance shop. |

|

|

2805 Ground Comm Electronics Maintenance Officer (WO-CWO5) |

Comm Bn. or at MSC level Comm CO or G6 shop. Duty expert on all matters regarding ground comm electronics maintenance. |

|

|

Preventative maintenance checks and services (PMCS) |

Systematic program consisting of inspecting, cleaning, servicing, lubricating and adjusting. |

|

|

First Echelon PMCS |

1. Daily 2. Monthly |

|

|

Second Echelon PMCS |

1. Quarterly 2. Semiannual 3. Annual 4. Biennial 5. Special |

|

|

The stages of corrective maintenance |

1. Isolating equipment malfunctions. 2. Obtain required repair parts. 3. Correct equipment faults. |

|

|

Maintenance Reports |

The maintenance tool that contains information that commanders use to determine policy, to plan, to establish controls, and to evaluate operations and performances. |

|

|

GCSS-MC |

The automated information system used to manage maintenance in the Marine Corps. |

|

|

Maintenance inspections in the Marine Corps |

1. Principal means available to the unit commander to ascertain whether planning and organization are sound, their staffs are functioning effectively, and directives are clear, well understood and being effected by subordinates. |

|

|

The difference between an inspection and a visit |

The absence of a senior commander or officer designated as an inspector. |

|

|

FSMAO Mission |

Identifying and reporting deficiencies in supply and maintenance operations and recommending remedial action. |

|

|

Duties of a commodity manager |

1. Serves as technical adviser to the commander on all commodity maintenance functions. 2. Schedules, directs, and supervises the case, inspection, and maintenance of the unit's equipment. 3. Coordinates effective repair parts support with the units supply officer. 4. Maintains staff responsibility for the operation and functioning of the unit's calibration control, PMCS, modification control and technical publications control program. 5. Supervises the maintenance/commodity operations for the unit. 6. Plans maintenance workload based on the maintenance level authorized, priority, availability of parts, tools, equipment, level of personnel experience and tactical situation. 7. Inspects equipment periodically and ensures that performed maintenance conforms to established standards and that equipment records are maintained. 8. Maintains staff responsibility for the operation and functioning of the GCSS-MC within the respective are of responsibility. 9. Plans and coordinates a program of resource management. 10. Analyzes maintenance information to evaluate equipment performance and maintenance production. 11. Acts as liaison with internal and external agencies on maintenance matters and coordinates efforts in the maintenance related programs. 12. Establishes maintenance production and quality control programs. |

|

|

Two categories of equipment that are MARES reportable |

1. Reportable Principal End Item (PEI) 2. Mission Essential Equipment (MEE) |

|

|

Supply/Equipment On-Hand |

|

|

|

Equipment Condition |

|

|

|

Material Readiness |

|

|

|

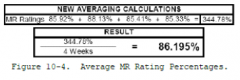

Average Readiness Ratings |

|

|

|

Status of Resources and Training System (SORTS) |

Provide commanders and up, including the National Command Authorities (NCA) a timely and accurate assessment of the status of the resources required by a unit to accomplish its wartime mission. |

|

|

MERIT |

A powerful, web-enabled tool which graphically depicts the current readiness posture and detailed supply and maintenance information for all Marine Corps readiness reportable TAMCNs. |

|

|

DRRS |

Intended to be a mission-focused, capability-based, net-centric, SIPRNET system that will establish new criteria to assess the ability of units and installations to execute their missions and Mission Essential Tasks. |

|

|

Global Combat Support System-Marine Corps (GCSS-MC) |

To enable streamlines processes and provide accurate, near real-time information both in garrison and in deployed environments. Allows commanders, logistics planners and operators to make decisions about their supply chain based on reliable information. Induct items into the maintenance cycle. |

|

|

Maintenance service request (SR) |

Used for all maintenance actions applied beyond the first echelon. Maintenance performed and requests for higher echelons of maintenance are recorded on the SR. |

|

|

Parts Request |

Often referred to as a shopping list, is used to requisition, receipt for, cancel and record partial issues and credits of repair parts and secondary reparable items associated with equipment being repaired. |

|

|

Maintenance Process Report (MPR) |

Contains complete maintenance and repair parts information regarding each service request opened by a section. |

|

|

Supply Readiness Report |

GCSS-MC report that lists each readiness (MARES) reportable TAMCN and the quantity authorized, possessed and excess. Mission essential equipment. |