![]()

![]()

![]()

Use LEFT and RIGHT arrow keys to navigate between flashcards;

Use UP and DOWN arrow keys to flip the card;

H to show hint;

A reads text to speech;

66 Cards in this Set

- Front

- Back

|

tin cannister |

1810, handmade, made from tin plate or iron plate, cut by hand, soldered by hand |

|

|

Hole and cap |

1810, had a filler hole in one end that is closed by cap. used for a brief period of time and then improved quickly as the swelled and burst. Made by hand, shaped with roller and overlapping edges were soldered together |

|

|

hole-in- cap |

by 1820, had a filler hole in one end that was sealed with tin plate cap that had a pinhole vent in the center, so that excess moisture and air could escape when heated, this reduced the number of leakers, the pinhole was then filled with drop of solder. Hand soldering was common until 1880s |

|

|

Stamped can ends |

1847, machine made can ends with extended edges that fit over the can body |

|

|

Key wind opened |

1866, closure mechanism in which as scored band on the side or top of the can can be removed rolling or tearing it away with the use of a key (sardine can) |

|

|

Tapered tin |

1875, base of tin is larger than the top, originally rectangular in shape, , first for processed meats,

|

|

|

Double side seam cans |

1888, a seam that locks the parts of a can together, |

|

|

Key-wind opened tapered tins |

1895, closure mechanism where a scored strip was placed on the can body near its larger end. the second scored strip was removed with a key, later frequently found on cylindrical coffee cans |

|

|

Ams can |

1898, cans without internal solder and that have their side seams, (top and bottom) closed by a double seam |

|

|

Hole-in-top |

After 1900, has a single pinhole or matchstick filler hole no larger than 1/8th of an inch in the center of one end, filled with a drop of solder. Used for evaporated milk, also known as venthole cans |

|

|

Sanitary can |

1904, made using double seams, airtight and do not need soldering to fasten seams, top or bottom, made by machine, interiors were lacquered to prevent chemical reaction, replaced hole-in-top |

|

|

TPQ |

Terminus post queum (earliest date deposited) To determine TPQ, find most modern thing

|

|

|

TAQ |

Terminus Ante Queum (latest date deposited) To determine TAQ, determine the TPQ of the upper deposit (not a true TAQ, events can define TAQ such as bulldozing, etc.) |

|

|

Parts of Nail |

Head Neck Shank Tip |

|

|

Kinds of nails? |

Wraught nails Cut nails Wire/wire pulled nails |

|

|

Wraught Nails manufacturing, history, and significance |

Oldest form, as early as 3000 BCE Egypt Manufacture: get rod of iron, form shank, hammer it to make the head (can see hammer marks). Made individually by hand. Historical significance: useful for tinkering in regards to frontier concept, reused as they were expensive. |

|

|

Wraught nail appearance |

uneven head, may have cracks Shank has 4 sides but is not uniform tip is slammed with sludge hammer |

|

|

Cut nails' manufacturing history |

Steam power and industrial revolution led to cut 1780s were earliest cut nails, machine made. Use plate stock instead of rods. 1820s begin making carpentry and architecture nails. 1830, large scale manufacturing. Early cut nails snapped in half because of horizontal striations in iron, eventually made vertical |

|

|

Cut nails' appearance |

Head had mold (rounded square ish) Square shank, have burrs, shank sides are even, wedged taper compared to wraught nails. Tips not sharp, rectangular tip |

|

|

Burrs |

On cut nails, reveals manufacturing process, older nails had burrs on opposite sides of shank corners. Newer cut nails had burrs on same side of shank corners (1840s in USA and 1860 in UK) |

|

|

Wire nails manufacturing and history |

made in late 18th century, initially made of copper and were only good for little things. 1870s made from Bessener Steel (needed high temperature for these) Used in USA by 1800s, started to become common by 1900, then would dominate market except for horse shoe nails. What we use today. |

|

|

Wire nails' appearance |

Round head grip marks on neck 4 sided tip |

|

|

Staffordshire-type Slipware |

Paste: Coarse earthenware Date range: 1675-1770 Origin: English Visual Description: buff or tan coloured body, covered in white and brown slip, with clear glaze that turns white slip yellow, brown slip can be combed, trailed or marbled |

|

|

Transfer Printed ware |

Paste: Refined white earthenware, also pearlware and creamware Date range: 1830-present Origin:English Visual Description: white paste with printing in blue, black, red, green, purple, or brown. No brush strokes. Fine lines and often tiny dots |

|

|

Ironstone |

Paste: refined earthenware Date range: 1840-1930 Origin: English Visual Description: Hard, white, thick body; may have greyish cast, usually undecorated, may have molded or printed decoration, thick clear glaze often with a network of very fine cracks |

|

|

Rockingham ware |

Paste: coarse earthenware Date range: 1850-1950 Origin: North America Visual Description: pale yellow body with mottled brown glaze, alkaline glaze |

|

|

White salt-glazed stoneware |

Paste: stoneware Date range: 1720-1770 Origin: England Visual Description: thin, hard white body with 'orange peel' texture; often molded decoration |

|

|

Shell edged ware |

Paste: refined earthenware (mostly pearlware, but can occur in creamware or whiteware) Date range:1780-1840 Origin: English Visual Description: white body; rims scalloped with impressed or embossed designs and blue or green (rarely red) colour |

|

|

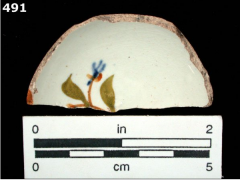

Tin-enamelled ware (Delftware) |

Paste: coarse earthenware Date range: 1630-1800 Origin: English, dutch Visual Description: buff or cream coloured with chalky texture; white or bluish-white glaze with a matte finish, which tends to chip off; can be undecorated or handpainted in blue or polychrome |

|

|

Celadon (winter green) ware |

Paste: Hard paste porcelain Date range: none Origin: Chinese Visual Description: translucent body with pale blue/green glaze; often with blue painted Chinese character on base, commonly cups or bowls |

|

|

Bamboo ware |

Paste: porcellaneous stoneware Date range: none Origin: Chinese Visual Description: grey body with a grey or greenish/bluish-grey glaze and blue or green painted decoration in a characteristic pattern; almost exclusively on bowls |

|

|

Handpainted whiteware |

Paste: refined white earthenware Date range: 1830-present Origin: English Visual Description: white body with painted floral and geometric decoration in red, green, blue, brown, black |

|

|

Creamware |

Paste: refined earthenware Date range: 1762-1820 Origin: English Visual Description: pale cream coloured body and glaze; can be plain, molded, or painted or transfer printed |

|

|

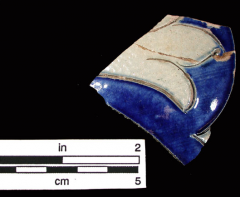

Rhenish stoneware |

Paste: stoneware Date range: 1650-1775 Origin: German Visual Description: grey body with blue or purple colour can have incised and molded decoration salt glaze produces an 'orange peel' texture |

|

|

Paste? |

body of what the vessel is made from |

|

|

Coarse Earthenware |

fired under 1100 C porous, coarse, not as heavy as there is air. Dominate medieval period |

|

|

Porcelain |

Fired at 1400 C |

|

|

Decoration |

Plain Slip (different colour clay painted on and fired) Glaze (vitriflying, makes glassy surface) |

|

|

Bisque firing |

form vessel, bisque firing, decorate, fire again |

|

|

Delftware history |

~1700 emerges, Dutch white glaze with blue image, imitating Asian porcelain (tin glazing), trying to figure out how they do it. other countries try as well. France (faince) Holland/England (Delft) Spain/ Portugal/Italy (Majolica/Mayolica) |

|

|

Stoneware |

Developed by Germans in 1400s Rhenish stoneware (1650-1775) Thicker, heavier, more vitrified, used for crocks in Canada. Does not hold glaze well, especially colours, usually monochrome, salt-glazed |

|

|

Dry-bodied Stoneware |

Invented in Asia used for teawares, popular in 18th century in Europe, reaches Europe in 1660s, can't initially figure out how it's made |

|

|

Chinese porcelain punch bowls |

in 1780s exported them to Europe, made ones they thought Europeans would like |

|

|

Europe and Porcelain |

Figured out how to make it in 1700s used koolin first used soft paste 1740s used hard paste 1750s bone china (cream) 1760s Europeans made refined white earthenware paste |

|

|

Molded ceramics |

1760s/1770s industrial factories made molded ceramics creamware in 1760s (yellowish) pearlware in 1780s (bluish) Can see colour pooled in cracks These faded out in 1820s |

|

|

Annularwares |

bands of colour 1770s to 1900 factory made

|

|

|

Spongeware and stampware |

refined white earthenware made for lower classes of people

|

|

|

Shell edged ware English 1780-1840 refined white earthenware |

|

|

Rhenish Stoneware 1650-1775 German |

|

|

Staffordshire slipware English 1675-1770 coarse earthenware |

|

|

Delftware Dutch Refined earthenware 1630-1800 tin-glazed |

|

|

White salt glazed stoneware English 1720-1770 orange peel texture |

|

|

Transfer print ware English 1830-present refined white earthenware |

|

|

Creamware 1762-1820 English refined earthenware |

|

|

Hand-painted white ware (image actually pearl) English 1830-present refined earthen ware |

|

|

Ironstone English 1840-1930 Refined earthenware |

|

|

Rockingham ware North America and England Coarse earthenware 1850-1950 |

|

|

Bamboo ware Porcelaneous stoneware no date range Chinese |

|

|

Celadon (winter green) ware Hard paste porcelain Chinese no date range |

|

|

Stoneware liquor bottle Chinese

|

|

|

hand-painted whiteware |

|

|

Staffordshire-style slipware |

|

|

Rockingham ware |

|

|

Rhenish Stoneware |

|

|

White salt glazed stoneware orange peel texture |

|

|

Chinese underglaze Porcelain Blue glaze, fired, other colours painted on and not fired. Ghosting occurs 1700-1780 |