![]()

![]()

![]()

Use LEFT and RIGHT arrow keys to navigate between flashcards;

Use UP and DOWN arrow keys to flip the card;

H to show hint;

A reads text to speech;

28 Cards in this Set

- Front

- Back

|

Flatness: A geometric tolerance used to control a surface which is designed to have all elements in the same plane. Flatness allows variation within two imaginary planes, separated by the given tolerance amount. With the 2009 standard, it may also be used on a centerplane of a feature of size.

|

|

|

Angularity: The geometric tolerance used to control a surface, axis, or center plane that is designed to be at a specified angle from a given datum.

|

|

|

Parallelism: The geometric tolerance used to control a surface, axis, or center plane that is designed to be parallel (zero degrees) in relation to a datum.

|

|

|

Circular Runout: The category of geometric tolerancing that controls a surface of revolution as compared to a datum axis other than its own. It can be used to control circularity, “wobble,” taper, and concentricity. The two types of runout are circular runout and total runout.

|

|

|

Perpendicularity: The geometric tolerance used to control a surface, axis, or center plane that is designed to be 90º to a datum.

|

|

|

Circularity: A geometric tolerance used to control all points on a surface, at any perpendicular cross-section, to be equidistant from the axis. Sometimes referred to as roundness.

|

|

|

Positional Tolerance: A geometric tolerance that controls the location of a feature of size. It defines a zone around the perfect location within which the axis or center plane of the feature is permitted to vary.

|

|

|

Concentricity: A geometric tolerance used to control the median points of all diametrically opposed elements of a circular feature, in order to be congruent with a datum axis. It is commonly misused; usually runout or position can suffice.

|

|

|

Profile of a Line: A geometric tolerance used to control line elements (taken at any cross-section in the plane of the given view) as they relate to the true profile. It may or may not reference datums.

|

|

|

Cylindricity: A geometric tolerance used to control a surface of revolution (inside or outside diameter) where all points are to be equidistant from a common axis. The cylindricity tolerance will control circularity, straightness, and taper.

|

|

|

Profile of a Surface: A geometric tolerance used to control a three-dimensional surface as compared to the true profile. It may or may not reference datums.

|

|

|

Straightness: The geometric tolerance applied to an axis or surface element which is designed to be perfectly straight. It may be applied to a surface (individual elements) or a feature of size (axis or centerplane).

|

|

|

Symmetry: The geometric tolerance used to control the median points of all opposed elements of two or more feature surfaces to be congruent with a datum axis or plane. It is commonly misused; usually position will suffice.

|

|

|

Total Runout: The category of geometric tolerancing that controls a surface of revolution as compared to a datum axis other than its own. It can be used to control circularity, “wobble,” taper, and concentricity. The two types of runout are circular runout and total runout.

|

|

|

Projected Tolerance Zone: A concept sometimes used in GD&T to indicate that a tolerance zone does not exist within the part itself, but is projected above the part surface. This is usually done to ensure that a fastener will assemble through multiple parts without interference.

|

|

|

Regardless of Feature Size: Abbreviated RFS, it is a term used to indicate that a geometric tolerance is the same, no matter what size the feature is made at. It is the presumed condition, unless the symbol for MMC or LMC is shown.

|

|

|

Tangent Plane:

|

|

|

Unilateral: Refers to unequal profile distribution.

|

|

|

Free State:

|

|

|

Least Material Condition: A number that represents the condition where a feature of size has the least amount of material, while still being within the given size limits. Thus, LMC would be the smallest pin (for an external feature) or the largest hole (for an internal feature).

|

|

|

Maximum Material Condition: Often abbreviated as MMC, the size of a feature of size when it contains the most material allowed (while still being within the acceptable size limits).

|

|

|

Datum: A theoretically exact point, axis, or plane derived by contact a datum feature; it then becomes the origin from which geometric characteristics are measured.

|

|

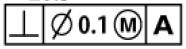

What is this called?

|

Feature Control Frame

|

|

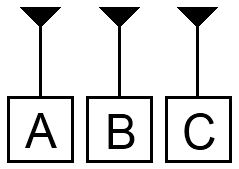

What are each of these objects called?

|

Datum frames.

A: Primary Datum B: Secondary Datum C: Tertiary Datum |

|

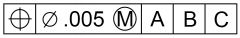

In this feature control frame, what information goes in the left, middle, and right boxes? What are the implied connecting words between the boxes?

|

Left: Geometric Symbol

Middle: Tolerance Information / Material Condition Symbol Right: Datum References The POSITION of the feature must be within a .005 DIAMETRICAL TOLERANCE ZONE AT MAXIMUM MATERIAL CONDITION relative to DATUMS A, B, AND, C. |

|

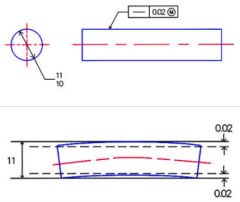

What is the difference between circular and total runout and how do you measure each in light of the above photo?

|

The worst circular runout error occurs at the slice with the greatest variation. In this case two slices vary a total of 0.03. Circular runout is measured by spinning the part in a full circle around the entire part.

Total runout is the difference between the highest and lowest readings found over the entire feature. The highest reading was +0.02 and the lowest reading was -0.09. Therefore, the total runout for the feature is 0.11, the difference between +0.02 and -0.09. |

|

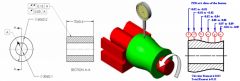

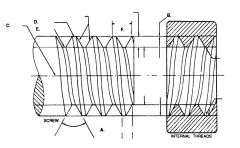

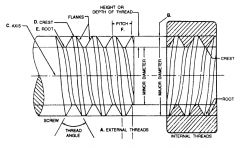

Define the names of the features shown.

|

|

|

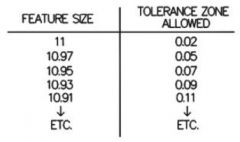

1) In the above example, what modifier lets you know that you can use GD&T to acquire a bonus tolerance? 2) What would be your total allowable tolerance for your flatness if the actual diameter of the above part measured 10.91mm

|

1) The "maximum material condition" modifier.

2) Plus or minus .11mm |