![]()

![]()

![]()

Use LEFT and RIGHT arrow keys to navigate between flashcards;

Use UP and DOWN arrow keys to flip the card;

H to show hint;

A reads text to speech;

63 Cards in this Set

- Front

- Back

- 3rd side (hint)

|

What are the principle and (some) secondary loads acting on a foundation? |

Principal: Combination of dead and live acting vertically on the superstructure. Secondary: wind-induced sliding, overturning, uplift, ground movements, pressure by surrounding soil and water, thrust from tensile or arched structures |

|

|

|

Settlement |

is the gradual subsiding of a structure as the soil beneath its foundation consolidates under loading. Some settlement is generally expected, slight and occurs rather quickly . |

|

|

|

True or false: When the foundation soil is a moist, cohesive clay, which has a relatively large % of voids, consolidation can be quite large and occur slowly over a longer period of time. |

True. A properly designed and constructed foundation system should distribute its loads so that whatever settlement occurs is minimal or is uniformly distributed under all portions of the structure. AKA DO NOT EXCEED BEARING CAPACITY |

|

|

|

Differential settlement |

is the relative movement of different parts of a structure caused by uneven consolidation of the condition soil. |

|

|

|

When would you use a shallow foundation system? |

When stable soil of adequate bearing capacity occurs relatively near to the ground surface. |

|

|

|

When would you use a deep foundation system? |

when the soil underlying a foundation is unstable or of inadequate bearing capacity. |

|

|

|

What are some factors to consider when selecting and designing the type of foundation system? |

Pattern and magnitude of building loads Subsurface and groundwater conditions Topography of the site Impact on adjacent properties Building code requirements Construction method and risk |

|

|

|

Underpinning |

is the process of rebuilding or strengthening the foundation of an existing building, or extending it when a new excavation in adjoining property is deeper than the existing foundation. |

|

|

|

What is the purpose of needle beams when underpinning? |

to provide temporary support , they are carried by hydraulic jacks and shores. |

|

|

|

What are two alternate methods to reinforcing/repairing/lowering a foundation? |

digging intermittent pits under the existing down to the new level. once the new foundation wall and footing sections are place additional pits can be dug. repeat until entire extent is complete.

construct piles or caissons on either side of the existing foundation, remove a section of foundation wall and replace it with a reinforced concrete pile cap. |

|

|

|

When the sides of a deep excavation exceed the angle of repose for the soil the earth must be temporarily braced or shored. What are some types of bracing or shoring? |

Soldier Piles with Lagging Sheet Piling (either of the above with tiebacks and/or wales |

|

|

|

Soldier Piles (or beams) |

are steel H sections driven vertically into the ground to support horizontal lagging |

|

|

|

Lagging |

is the heavy timber planks joined together to retain the face of an excavation |

|

|

|

Sheet Piling |

consists of timber, steel or precast concrete planks driven vertically side by side to retain earth and prevent water from seeping into an excavation |

|

|

|

True or False, Steel and/or precast sheet piling may be left in place as part of the substructure of a building rather than removed afterwards. |

True |

|

|

|

Tiebacks |

consist of steel cables or tendons that are inserted into holes predrilled through the sheet piling and into rock or a suitable stratum of soil, grouted under pressure to anchor them to the rock or soil and post-tensioned with a hydraulic jack. they are then secured to continuous, horizontal steel wales to maintain the tension. |

|

|

|

Dewatering |

is the process of lowering a water table or preventing an excavation from filling with groundwater |

|

|

|

What is the term for when perforated tubes "wellpoints" are driven into the ground to collect water from the surrounding area so that it can be pumped away. |

Dewatering

|

|

|

|

What factors contribute to the designed contact area of a spread footing? |

magnitude of forces and the allowable bearing capacity of the soil |

|

|

|

What is the typical compressive strength of concrete in a foundation wall/footing foundation? |

2500 psi (17kPa) at 28 days |

|

|

|

When is reinforcing in a spread footing required? |

when the footing projects more than half of the foundation wall thickness, because it is subject to bending.

(generally 6" of concrete is required above reinforcing and 3 inches clearance below the reinforcing ) |

|

|

|

What is the frostline? |

the average depth at which soil is frozen or frost penetrates the ground. (4' in toronto?) |

|

|

|

What are some types of spread footings and their defining characteristics? |

Strip footing - continuous footing at the base of a foundation wall Isolated footing- individual spread footing supporting freestanding columns/piers Continuous footing - extended to support multiple piers/columns Grade beam - concrete beam supporting a bearing wall transferring loads to isolated footings spaced along the wall. Stepped footing - strip footing that changes level in stages Cantilever or strap footing - a column footing connected by a tie beam to another footing Combined footing - footing for a perimeter foundation wall extended to support an interior column load. |

|

|

|

What is the term for a heavily reinforced concrete slab that serves as a single monolithic footing for a number of columns or an entire building? |

Mat or Raft Foundation |

|

|

|

What are the purposes of crawl spaces? |

To provide space under a first floor for the integration of and access to mechanical, electrical and plumbing installations. |

|

|

|

What is the function of a 'key' in a foundation assembly |

it locks the foundation wall to the footing & provides additional resistance to lateral slippage |

|

|

|

What are some types of concrete based foundation wall construction? |

Cast-in-place Concrete - requires formwork and access to place the concrete Concrete Masonry - easily handled small units, no formwork, modular |

|

|

|

What is an integral piece of the transition between a wood framed construction and concrete foundation wall? |

Sill Plate anchors or holddowns, to secure the framing to the foundation against uplifting or seismic forces. |

|

|

|

What is used between the sill plate and the top of the foundation wall to reduce air infiltration? |

a fibrous sill sealer |

|

|

|

How deep are anchor bolts typically installed in to the concrete of the foundation wall? |

at least 178mm & 1829 o.c. |

|

|

|

What is an important requirement of wood that will be use in a foundation system? |

It must be pressure treated wood Note: all metal fasteners should be of stainless steel or hot-dipped zinc-coated steel. |

|

|

|

What is the effective depth of a footing? |

effective depth (d) is the distance between the top of reinforcing and below the top of the footing. |

|

|

|

What is the purpose of a steel base plate on a column? |

to distribute the column load over an area wide enough that the allowable stresses in the slab are not exceeded. |

|

|

|

What is the typical term for a wood column base connection? |

Post base. |

|

|

|

What are some general requirements when locating a foundation adjacent to ground slopes exceeding 100% (45 degrees)? |

- Set the face of the footing back from the top of a slope enough to provide vertical and lateral support for the footing and prevent settlement (height of slope/3 to a max 12 m, ) - Set face of structure away from the toe of a slope enough to protect against site drainage and erosion (height of slope/2 to a max 5m) - Avoid closely spaced or adjacent footings at varying levels (can cause overlapping soil stress). Use stepped footings to accommodate sloping grade. (steps should be at least 610 long and the drops should be not more than 610. |

|

|

|

What is the bearing prism of a footing? |

Is the area under a footing that reflects the clearance required below it, it is somewhat soil dependent but is accepted generally to be 45 degrees |

|

|

|

What are the conditions required for a concrete slab on grade? |

The grade must be level, stable, uniformly dense and/or properly compacted with no organic matter. If these conditions are not met a mat or raft foundation would be best, requiring engineering consulting & design. |

|

|

|

What is the purpose of steel reinforcing in a concrete slab? |

Controls thermal stresses, shrinkage cracking, and slight differential movement in the soil bed; it can also provide additional support for heavier-than-normal loads. |

|

|

|

What can be added to the concrete mix to reduce shrinking? |

Glass, Steel or polypropylene fibers. Concrete additives can also increase surface hardness and abrasion. |

|

|

|

What is the recommended depth of sand under the concrete slab on grade to absorb excess water from the concrete during curing? |

51mm |

|

|

|

What layer of the slab on grade assembly provides protection against the capillary rise of groundwater? |

100mm (min) of gravel or crushed stone. |

|

|

|

What are some typical maximum width/length dimensions for Slabs on grade? |

max 14m - 22 m depending on the wire size |

|

|

|

What is the typical spacing of reinforcement wire in a slab on grade? |

150x150mm |

|

|

|

What are the three types of joints used to accommodate movement in the plane of a concrete slab on grade? |

Isolation Joints - aka expansion joints, allow movement to occur between a slab and adjoining columns and walls Control Joints - create lines of weakness so that the cracking (tensile stresses) occurs along predetermined lines. Construction Joints - provide a place for construction to stop and continue later, they also serve as isolation or control joints, and can be keyed or doweled to prevent vertical differential movement of adjoining slabs. |

|

|

|

What is the typical spacing of control joints? |

4.6 to 6.1m, or wherever required to break an irregular slab shape into rectangular-square sections. |

|

|

|

What are some types of control joints? |

Sawn (filled with joint filler) Premolded/metal strip Keyed |

|

|

|

When should an independent footing be used? |

When a bearing wall or column transmits a heavy or concentrated load. (a concrete SOG may be thickened to support an interior bearing partition or post) |

|

|

|

When is it appropriate to use a Thickened Edge Slab rather than a typical footing assembly? |

in warm or temperate climates where little to no ground frost occurs. It is economical Thickened edge slab = thickened edges of a concrete slab on grade to form integral footings for the exterior walls. |

|

|

|

What is the typical thickness of concrete around a slab embed for heating ducts? |

51mm minimum. |

|

|

|

What is the typical thickness of the toping used with in-floor-heating (aka embedded copper or polybutylene piping)? |

40-75mm cover Note: underslab insulation is recommended |

|

|

|

What is the typical thickness of the angled slab at slab steps? |

100mm minimum between the bottom of angled slab and the line connecting the bottom of the risers. |

|

|

|

What size of opening would require reinforcing of a slab on grade? |

anything larger than 305mm |

|

|

|

When would you use a pole foundation? |

On a timber structure project where the intent is to preserve the natural features of the site and/or the area is subject to steel slopes or periodic flooding. They also require minimal excavation. |

|

|

|

What is required in a pole foundation assembly to provide rigidity and resistance to lateral forces? |

Adequate embedment length Suitable backfilling Proper connections (Floors designed and constructed as a diaphragm) |

|

|

|

What are some types of connections at the top and base of a pole foundation? |

Top: Notching/dapping - good for round poles, must be treated with preservative/protection Spiked Grid Connector - better than notched and bolted connection Gusset - used when piers/poles terminate at the first floor, beams bear directly on the pier/pole and are secured with gussets or metal connectors. Bottom: Footing - with tamped backfill of clean sand, gravel or crushed rock above. Necklace/ Collar - with tamped backfill of clean sand, gravel or crushed rock below. Concrete or soil-cement backfill - can reduce the required embedment length, required on steep slopes with average to below average soils. |

|

|

|

What are the two principle types of deep foundations? |

Piles and Caissons |

|

|

|

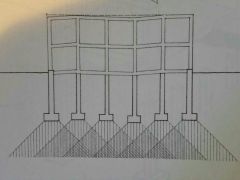

What are the defining characteristics of Pile foundations? |

- A system of end-bearing or friction piles, pile caps and tie beams - Driven in clusters of 2 or more - Can be: treated timber poles, composite, steel H sections (sometimes encased in concrete), heavy steel pipes (capped or filled with concrete), concrete-filled pipes or precast reinforced or prestressed concrete (can have a round, square or hexagonal cross-section), cast-in-place (cased or uncased) - Driven into the earth by a pile driver |

|

|

|

What is the most common types of Piles? |

Precast reinforced or Prestressed concrete. |

|

|

|

How are the allowable loads on a pile established? |

a Dynamic pile formula, static load test or a geotechnical investigation of the foundation soil. |

|

|

|

What are micropiles? |

They are high capacity, small diameter (125-305mm) piles used for foundations in urban areas (restricted access areas) for underpinning or emergency repairs. They are drilled and grouted in-place and are typically reinforced. |

|

|

|

What are the defining characteristics of Caisson foundations? |

Note: they are also referred to as drilled piles or piers. - Cast-in-place, plain or reinforced and formed by: boring with a large auger to a suitable bearing stratum & filling the shaft with concrete. - Reinforcement at upper part of shaft provides additional resistance to bending - Temporary casing used to seal out water, sand or loose fill during excavation. - Base may be enlarged into a bell shape (typ 60 degrees) to increase bearing |

|

|

|

What is the typical boring for a caisson and why? |

760 or larger in diameter to permit inspection at the bottom. |

|

|

|

What are socketed and rock caissons? |

Socketed : drilled into stratum of solid rock. for additional frictional support Rock: socketed caissons that have a steel H section core within a concrete-filled pipe casing. |

|