![]()

![]()

![]()

Use LEFT and RIGHT arrow keys to navigate between flashcards;

Use UP and DOWN arrow keys to flip the card;

H to show hint;

A reads text to speech;

13 Cards in this Set

- Front

- Back

- 3rd side (hint)

|

Production methods: Job |

ONE AT A TIME Pros: bespoke. To your measurements Very motivated workers & simple product organisation. Cons: Skilled labour and craftsmen is expensive Wide range of tools may be required Long lead time between start and finish High selling costs |

Wedding dress *dances like Taeyang* |

|

|

Method of production: Batch |

MORE THAN ONE AT A TIME Goods can be switched over to make something different on the same production line. Pros: Production can be changed according to demand. Standard production, less labour Employers specialise to become good at their job Lower skilled workers, lower wages paid. Cons: Small batches have higher average units costs (EOS) Workers become less motivated with repetitive work Idle time between batches need to be managed. |

Cakes, pottery, furniture. |

|

|

Production methods: Flow/continuous. |

FLOW IN A CONTINUOUS PROCESS WITH MACHINARY. Requires semi skilled workers and produces alot.

Pros: Average cost per units are lower due to large quantities. Automaised and computerised production= best quality and designs. Stocks and materials can be held & ordered JIT basis.

Cons: high set up costs Low motivation of staff, repetitive tasks. Break down & lost production may be costly |

|

|

|

Production method: Cell |

GROUPS OF WORKERS WITH DIFFERENT SKILLS. Pros: minimal handling of product reduces costs. Motivating for workers to see completed product. Lead times reduced Less time moving place to place. Cons: May be tension in or between cells if work gets competitive. Huge investment in machinary for each cell |

|

|

|

Productivity |

How efficient a firm is. The amount a worker makes hence LABOUR. Measurements will be different depending on industry. Measurements may be hard to QUANTIFY on larger products. |

|

|

|

Ways to improve productivity |

JIT (just in time) TQM (total quality management) Cell production: reconstruction of manufacturing layout Imployee motivation: financial |

|

|

|

FORMULAS |

LABOUR PRODUCTIVITY = output (time period) ÷ No. Of employees (per time period) ×100 CAPITAL PRODUCTIVITY = Output ÷ capital employed (cost of machinary) ×100 |

|

|

|

Factors influencing productivity |

Quality of inputs (materials) Labour shift organisation of workers ( optimum amount of employees) Investment in new technology. |

|

|

|

Link between productivity and competitiveness |

More produced= more competitive the prices (economy efficient) Business will enjoy EOS Mote efficient business (EOS) |

|

|

|

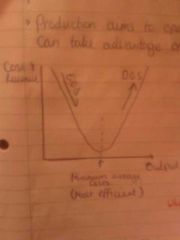

Efficiency |

Production at minimum average costs. EOS goes down as output increases. DIS Av cosgs go up as output increases |

|

|

|

Efficiency formula |

Av cost = total cost ÷ output Where Totsl cost = fixed cost + variable cost |

|

|

|

Productivity and efficiency |

Firms have higher output per employee are more efficient Can lead to COMPETITIVE ADVANTAGE and prices are LOWER THAN COMP. Can become MARKET LEADER ( low prices/ high prices compared to production costs) QUALITY MAY SUFFER AS A RESULTS OF TRYING TO PRODUCE ITEMS TOO RAPID |

|

|

|

Intensives |

Labour intensive = a lot of workers working intensely. (Sweatshops) Capital intensive = has more machinary than people. |

Apple, cars |