![]()

![]()

![]()

Use LEFT and RIGHT arrow keys to navigate between flashcards;

Use UP and DOWN arrow keys to flip the card;

H to show hint;

A reads text to speech;

122 Cards in this Set

- Front

- Back

|

What is a composite material? |

A composite material consists of two (or more) different materials whose mechanical properties complement each other although they maintain |

|

|

In aircraft engineering terms, a composite usually consists of what? |

a plastic resin matrix and reinforcing fibres of various materials. |

|

|

composite materials are increasingly used in |

their strength to weight ratio and corrosion |

|

|

(Nomenclature of Glass Fibre) A single fibre of glass usually between 5 and 14 |

Filament |

|

|

(Nomenclature of Glass Fibre) A lubricant used on the fibres during manufacture, it is burnt off prior to twisting |

Size |

|

|

(Nomenclature of Glass Fibre) A compound used to coat the filaments to improve handling and bonding characteristics. It must be compatible with the resin system used. DuPont "Volan A" is a common finish used with glass fibres. |

Finish |

|

|

(Nomenclature of Glass Fibre) A number of filaments bonded together with a size |

Strand |

|

|

(Nomenclature of Glass Fibre) The weight of a strand in grammes/kilometer, |

TEX Count |

|

|

(Nomenclature of Glass Fibre) Loose combination of strands with no twist. |

Roving |

|

|

(Nomenclature of Glass Fibre) One or more strands with applied twist of 20 - 40 turns per metre. |

Single Yarn |

|

|

(Nomenclature of Glass Fibre) Two or more single yarns with applied twist in the opposite direction to the single yarn twist. |

Plied Yarn |

|

|

(Nomenclature of Glass Fibre) A roll or spool of Roving or Yarn prior to weaving into cloth or chopping for mat. |

Cheese |

|

|

(Nomenclature of Glass Fibre) The name given to the longitudinal direction of the fibre in woven fabric, i.e. Warp Yarns; Yarns running the length of the fabric. |

Warp |

|

|

(Nomenclature of Glass Fibre) The transverse direction of the fabric, or yarns running crosswise |

Weft |

|

|

(Nomenclature of Glass Fibre) A roll of cloth. |

Bolt |

|

|

(Nomenclature of Glass Fibre) Woven edge reinforcement of fabric which must be trimmed off before use. Woven tape also has edge reinforcement but this may be incorporated in a repair. |

Selvedge |

|

|

(Styles of woven fabrics) Fibres only produce their greatest strength when they are? |

perfectly straight |

|

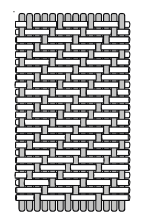

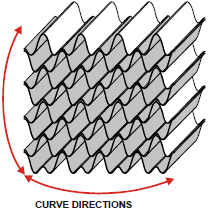

What kind of weave is this? |

Four Harness Satin Weave |

|

what kind of weave is this? |

Plain weave |

|

|

Most high strength primary structures are composed of what? |

uni-directional material |

|

what kind of weave is this? |

2 x 2 Twill weave |

|

|

(storage) To prevent the condensation of moisture on the cloth before use, the material must be allowed? |

Reach room tempature |

|

|

Some glass fibre cloth is supplied pre-impregnated with resin (Prepreg) and must be stored in a freezer at what tempature? |

-18°C or below |

|

|

For the integrity of aircraft repairs, it is essential that the glass cloth is undamaged and not contaminated with oil, grease, dust or moisture. Glass fibre fabric should, therefore, be stored horizontally in suitably protected rolls on cradles at an ambient temperature not exceeding °C and humidity not exceeding % relative humidity |

20°C and humidity not exceeding 65% relative humidity. Fabric must not be stored flat, folded or on end as the fibres are easily damaged. |

|

|

Aramid fibres are made from? |

aromatic polyamide |

|

|

Aramid fibre has the ability to? |

stretch under load then return to its original |

|

|

However, aramid fibre has a lower ___________ than carbon? |

compression strength |

|

|

Aramid fibres are resistant to what? |

high temperatures and fire |

|

|

(Carbon fibres) The fibres are manufactured by the controlled heating of Polyacrilonitrile (PAN), polythene or rayon fibres (e.g. Courtelle, Acrilan, Orlon) in a furnace filled with an inert gas. The fibres are pre-oxidised at °C? |

200-300°C for ONE hour |

|

|

(Carbon fibres) Then carbonised at what? |

1200°C |

|

|

(Carbon fibres) then graphitised at what tempature? |

2000 - 3000ºC |

|

|

(Carbon fibres) This process removes what? |

the hydrogen, nitrogen and oxygen leaving long |

|

|

A low density, high tenacity fibre with good impact resistance but low modulus. Its lack of stiffness usually precludes it from inclusion in a |

Polyester |

|

|

In random orientation, ultra-high molecular weight polyethylene molecules give very low mechanical properties. However, if dissolved and drawn from solution into a filament by a process called gel-spinning, the molecules become disentangled and aligned in the direction of the filament. The molecular alignment promotes very high tensile strength to the filament and the resulting fibre. Coupled with their low S.G. (<1.0), |

Polyethylene |

|

|

A very high silica fibre material similar to glass but with much higher |

Quartz |

|

|

Carbon or metal fibres may be coated with a layer of boron to improve the overall fibre properties. The extremely high cost of this fibre restricts it use to high temperature aerospace applications and in specialised sporting equipment. composed of carbon fibres interspersed among 80-100mm boron fibres, in an epoxy matrix, can achieve properties greater than either fibre alone, with flexural strength and stiffness twice that of HS carbon and 1.4 times that of boron, and shear strength exceeding that of either fibre. |

Boron |

|

|

fibres, usually in the form of very short ‘whiskers’ are mainly used in areas requiring high temperature resistance. They are more frequently associated with non-polymer matrices such as metal alloys. what is it? |

Ceramics |

|

|

(Resins) Man-made polymers are generally called |

‘synthetic resins’ or simply ‘resins’ |

|

|

(Resin) like metals, soften with heating and eventually melt, hardening again upon cooling. This process of crossing the softening or melting point on the temperature scale can be repeated as often as desired without any appreciable effect on the material properties in either state. Typical types include nylon, polypropylene and ABS, and these can be reinforced, although usually only with short, chopped fibres such as glass. what kind of resin is it? |

Thermoplastics |

|

|

(Resin) formed from a chemical reaction in situ, where the resin and hardener or resin and catalyst are mixed and then undergo a non-reversible chemical reaction to form a hard, infusible crystalline polymer. Heat can be used to accelerate the cure process and also improves the strength of the resin, but overheating damages the molecular bonds |

Thermosetting Plastics |

|

|

(Resin) Once cured, thermosets will not become liquid again if heated, although above a certain temperature their mechanical properties will change significantly. This temperature is known as the? |

Glass Transition Temperature (Tg) |

|

|

(Thermosetting Resins) Two or three part systems. Good environmental resistance. Heat resistant up to150ºC. Used as wet resin and prepreg, it produces toxic fumes (styrenes) during the cure process. Easily fire retarded but produces a lot of smoke when burning. Not as strong as epoxy. Was used extensively for aircraft but use now diminishing. Can be dangerous if mixed incorrectly (risk of explosion). |

Polyester |

|

|

(Thermosetting Resins) Very strong, good environmental resistance. Can |

Epoxy |

|

|

(Thermosetting Resins) Used where operation at higher temperatures than bismaleimides can stand is required (use up to 250°C wet/300°C dry). Typical applications include missile and aero-engine components. Extremely expensive resin, which uses toxic raw materials in its manufacture. Polyimides also tend to be hard to process due to their condensation reaction emitting water during cure, and are relatively brittle when cured |

Polyimides |

|

|

(Thermosetting Resins) Fairly brittle system but has a good fire/smoke toxicity performance. Hence extensive use in |

Phenolics |

|

|

(Epoxy Resins) These systems are mainly used for components that will meet elevated temperature conditions in service and are most resistant to moisture |

350ºf (177ºC) Cure Epoxy Systems |

|

|

(Epoxy Resins) These systems are used on less highly loaded structures such as fairings and access panels and are less resistant to elevated temperatures and |

250ºf (121ºC) Cure Epoxy Systems |

|

|

(Epoxy Wet Resins) These are usually two part systems Part A..which is? & Part B....which is? |

Part A:- is a polyepoxide resin (base resin)

Part B:- is a curing agent (hardener) |

|

|

(Epoxy Wet resins) what is Pot Life? |

Usable life of resin in the Pot (mixing receptacle). The pot life may be extended by decanting the mixed resin into smaller units because this |

|

|

(Epoxy Wet resins) This is the usable life after resin has been wetted into reinforcement and before it begins to gel.. what is it? |

Work Life |

|

|

(Epoxy Wet resins) On addition of the hardener a resin will begin to become more viscous until it reaches a state when it is no longer a liquid and has lost its ability to flow. This is what? |

Gel Point |

|

|

(Epoxy Wet resins) Wet resins will usually cure at ambient temperatures _________ºC in _________ hours though they will harden in less time than this. Cure can be accelerated (and properties improved) by the addition of heat. |

cure at ambient temperatures (21-24ºC) in 16-72 |

|

|

(Resin/Fibre Ratio) Depending on the fibres and resins used different rations will be used. However polyesters ratio is usually about _______ parts of resin to ________ part of fibre by weight |

two parts of resin to one part of fibre by weight |

|

|

(Prepregs) What is a prepreg? (an abbreviation of pre-impregnated)

|

is a sheet of fibre cloth or tape impregnated with the resin/hardener system. |

|

|

(Prepregs) Different kinds of prepegs are available list some different kinds?

|

|

|

|

(Prepregs) Because the prepreg material contains only enough resin to cure its own fibres it must be bonded to the substrate with a separate adhesive. This is usually in the form of what? |

A thin layer of thickened epoxy resin known |

|

|

(Prepregs) The backing film on cloth and tape material usually has a diamond pattern embossed on it. The long diagonal of the diamond indicates the _______ direction? |

Warp |

|

|

(Prepregs) To prevent premature cure, prepregs and film adhesives must be transported and stored at?

|

Very low tempatures |

|

|

(Prepregs)

Prepregs and film adhesives are stored in a sealed bag at? |

-18ºC |

|

|

(Workshop Conditions for Good Bonding) (Storage) If applicable allow kits of resin to reach ambient temperature before opening. Resin storage categories: List the label colour and temperature of each Category?

|

|

|

|

(Composite Construction) Fibre reinforced plastic resins can be used as? |

|

|

|

(Composite Construction) Describe a Laminate?

|

A structure built-up from layers of cloth impregnated with resin |

|

|

(Composite Construction) Describe a Sandwich? |

laminated skins separated by a light weight core, |

|

|

(Composite Construction) Sandwich construction represents by far the most common use of composite materials on most aircraft. This structure consists of two |

tension and compression loads |

|

|

(Composite Construction) And the core takes what load? |

shear loads |

|

|

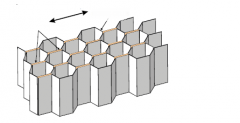

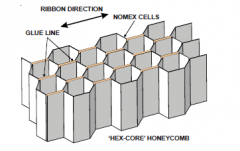

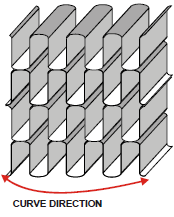

(Composite Construction) This ‘honeycomb’ structure can be made |

|

|

|

(Composite Construction) Nomex offers what ratio of its properties? |

very high strength to weight ratio and excellent resistance to moisture and fire |

|

|

(Composite Construction) The cell size of a honeycomb dictates what properties?

|

density, weight and strength of the honeycomb |

|

(Composite Construction) Label the parts and name the honeycomb structure?

|

"HEX CORE" |

|

(Composite Construction) Name the honeycomb structure? |

"OX-CORE" |

|

(Composite Construction) Name the honeycomb structure? |

"FLEX CORE" |

|

|

(Composite Construction) The advantages of monolithic structures include? |

weight reduction compared to conventional construction |

|

|

(Composite Construction) Non-conductive materials such as glass and aramid composite panels are often treated with a coat of what? |

conductive paint, or have a metallic mesh |

|

|

(Composite Cure) What is an autoclave? |

Autoclaves are pressurised ovens ranging in size from bench-top units to large plant with a working chamber large enough to accommodate a fuselage section or whole wing box |

|

|

(Composite Cure) For aerospace use these autoclaves produce how many bars of pressure? and apply what tempature? |

they apply a pressure of around 15 bar and temperatures up to about 250°C. |

|

|

(Composite Cure) is a portable computer based control unit which may be used to perform repairs in situ on the aircraft. It can be programmed to control the heating devices and produce a vacuum to compact the repair while recording the values achieved during the cure cycle. what is it? |

"Hot Bonder" |

|

|

(Composite Cure) Heat may be provided by lamps or more commonly electrical mats. It is monitored by what? |

Thermocouples |

|

|

(Inspection and Damage Assessment) Some of to day’s more common methods of Non-Destructive Inspection? |

|

|

|

(Inspection and Damage Assessment) Thermal photography (Thermography) can be used to survey large areas of the airframe in service and will reveal water damage. The area of interest is photographed or scanned with a thermal imaging camera immediately after landing. Any water in the structure will act as a heat sink and will appear as a cold point on the structure..what is this? |

Thermal Imaging |

|

|

(Inspection and Damage Assessment) The scanner fires a low power laser at the surface and analyses the reflection. Once calibrated on a suitable test piece it will give a quite accurate reading of the maximum temperature encountered by the structure under examination... what kind of inspection is this? |

Spectroscopy |

|

(Composite Repairs) Name this sanding repair?

|

Step sanding |

|

(Composite Repairs) Name this sanding repair?

|

Taper sanding |

|

|

(Composite Repairs) Mix sufficient resin to bond in lower repair ply and core. Work resin into cloth between melamine sheets, cut to size/shape, peel melinex from one side, place in hole in correct orientation and remove other melinex. what kind of repair is this? |

Wet Lay-up |

|

|

(Composite Repairs) Remove one backing paper and lay film adhesive in hole. Remove other backing paper and insert repair ply/s observing orientation. Apply film |

Prepreg Lay-up |

|

|

(Cutting and Drilling Composites) Great care needs to be employed when cutting and drilling composites. Due to their nature, glass and carbon fibres will prematurely do what to metal edges very quickly? |

Blunt them |

|

|

(Cutting and Drilling Composites) Generally high speeds and low feeds are required and ____________ cutting tools will give longer life and better finish? |

Carbide |

|

|

(Cutting and Drilling Composites) For trimming material, to get the best results we use? |

diamond grit cutters and silicon carbide abrasives |

|

|

(Cutting and Drilling Composites) The drills normally specified will be either shallow ________ ________ multi-start bits (e.g. “Klenk” drills) or flat bladed drill/__________ (“Dreamers”). These will be used to open holes produced by tungsten carbide pilot drills. |

helix angle & Reamer

|

|

|

(Fibre/Metal Laminate (FML)) Currently a glass fibre/aluminium composite known as ‘___________’ is being used to form the upper skin panels of the Airbus A380?

|

GLARE |

|

|

(Fibre/Metal Laminate (FML)) This material is both __________ than conventional sheet metal, and has better _________ resistance and lower ____________ propagation

|

|

|

|

(Fibre/Metal Laminate (FML)) GLARE has very good ________________properties, but limited resistance to ___________ loads. Its use is, therefore, restricted to areas of predominant tensile load such as the fuselage crown skin area. |

|

|

|

(Other Non-metallic Materials) Plastics

|

|

|

|

(Plastics) PVC is a thermoplastic material often used to replace rubber for making protective gloves and aprons. It is also used to make seat covers in light aircraft. A plasticiser can be added to PVC to soften it. PVC can be shaped by injection moulding and extrusion. It can also be compression moulded without a plasticiser to give a tough rigid material. |

Polyvinyl Chloride (PVC or Vinyl) |

|

|

(Plastics) Produced under brand names such as DuPont's 'Teflon', PTFE is a fluorocarbon-based polymer which has a very high resistance to most chemicals at temperatures from -80°C to>200°C and very low friction |

PolyTetraFluoroEthylene |

|

|

(Plastics) Laminates are made by pressing together sheets of cotton or linen which have been soaked in a thermosetting plastic resin. |

Tufnol and Micarta Laminates |

|

|

(Plastic Transparencies - Perspex) For aircraft purposes, formed Perspex is supplied in two grades:

What is Grade One perspex?

What is Grade Two perspex? |

Grade one:- which is free from optical distortion on both flat andcurved surfaces. Used for panels where undistorted vision is essential

Grade Two:-which may have slight irregularities and some optical distortion. Used for passenger windows, lamp coversetc., and authorised repairs. |

|

|

(Elastomers) Elastomers will tolerate repeated ____________ and return to their original size and shape, in a similar way to natural rubber. Some of the more common ______________,

|

|

|

|

(Elastomers) Some of the more common elastomers, to be found in the aerospace industry include;

|

|

|

|

(Ceramics) for applications where dust and moisture readily collect. These materials can be moulded into special shapes before being fired and glazed rather as crockery is. The porcelain-type insulators on high-voltage transformer and switch gear bushings, and on high-voltage |

Porcelain and Steatite |

|

|

(Ceramics) have been used for some times for such applications as motor vehicle spark-plug insulators and special electrical components. |

Special ceramics |

|

|

(Ceramics) is used for flight deck windows. Due to the high impact resistance and low erosion requirements they are usually composed of laminations of soda-lime glass, toughened glass and acrylic material with heating elements built in. The composition varies with type and manufacturer.. what is it? |

Glass |

|

|

(Ceramics) compositions are for high temperature insulation applications. what is it? |

Mica-glass |

|

|

(Ceramics) Are used in heat resistant blankets and to weave |

Ceramic Fibres |

|

(Adhesives)

What kind of adhesive bond is this? |

Mechanical |

|

(Adhesives)

What kind of adhesive bond is this? |

Chemical |

|

|

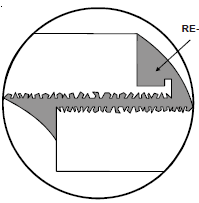

(Adhesives) Types of bond

Mechanical?

|

here the adhesive penetrates into the surface and forms a mechanical lock, by keying into surface irregularities. It also forms re-entrants, where the adhesive penetrates behind parts of the structure, and becomes an integral part of the component to be joined.

|

|

|

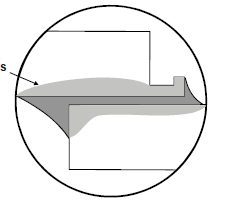

(Adhesives) Types of bond

Chemical? |

in this method of bonding, the adhesive is spread over the surfaces to be joined and forms a chemical bond with the surface, it's molecules diffusing into the substrate. |

|

|

(Adhesives) Stresses on a bonded joint |

|

|

|

(Adhesives) The major disadvantages associated with adhesive bonding are? |

|

|

|

(Types of adhesive) Flexible adhesives are used when? |

Flexible adhesives are used when some flexing, or slight relative movement of the joint, is essential and where high load-carrying properties are not paramount. In general, flexible adhesives are based on flexible plastics or elastomers. They are used for internal decorative trim etc. Examples include Evostik and Tretobond. |

|

|

(Types of adhesive) Structural adhesives are primarily aimed at? |

aimed at applications where high loads |

|

|

(Adhesives) Various acids can be used for the etch process including hydroflouric acid and sulphuric acid. Appetures and crevices must be sealed prior The Phosphoric Acid Non-Tank Anodising (PANTA) process is commonly used. The prepared area is coated with phosphoric acid gel and layers of gauze and acid gel laid on top. A stainless steel mesh is placed above this and coated with the gel. The work piece and mesh are connected to a DC power source so that the skin forms the anode (+) and the mesh |

Acid etching/anodising of existing surface |

|

|

(Adhesives) The adequacy of the anodising must be checked. This is done by observing the surface through a filter with fluorescent or daylight at a low angle of incidence. Rotating the filter will cause the original colour to change to a complimentary colour. If the colour change is not observed or is patchy, the cleaning and anodising processes must be repeated... what kind of test is this? |

Polarised light test |

|

|

(Adhesive) Within 2 hours of anodising, the area must be reprotected with primer. Normally an epoxy based Adhesive Bonding Primer is specified producing a coating 0.00015 - 0.0004 thick. This should be air dried or infrared heated to 93°C (200°F). Some primers require curing at 93°C (200°F) and this should be done within the specified time period... what is this? |

Epoxy priming |

|

|

(Adhesive) Repair assembly is similar to ___________ composite lay-up.

and is called? |

Prepeg

Repair Lay-up |

|

|

(Jointing Compounds) These materials are sometimes known as 'yellow chromate' or 'zinc chromate' or by trade names such as Duralac, JC5A and more recently Mastinox. They are used for the wet assembly of metallic mating surfaces in non-pressurised areas. Available in tubes, cans and drums, aircraft grade compounds do not dry and remain flexible throughout their working |

Chromate Based Jointing Compounds |

|

|

(Jointing Compounds) Hylomar is one of several sealants used on bolted flange joints for engine and component assembly. It seals metal to metal joints and is resistant to water, fuel, oil, most chemicals and combustion products. It seals surfaces with imperfections and withstands vibration, heat and expansion?

|

Hylomar |

|

|

(Sealants) Typical of the multi part sealants used is _______________. This two part polysulphide compound is comprised of a base and an accelerator and

|

PR 1440 |

|

|

(Sealant Application) The length of time it takes for the sealant to be no longer tacky or sticky? is called what? |

Tack Free Time |

|

|

(Sealant Application) Application Time for PR 1440 (Type A1/2) & (Type A2) |

(Type A1/2) = 30 mins

(Type A2) = 2 hours

|

|

|

(Sealant Application) Tack free time for PR 1440 (Type A1/2) & (Type A2)

|

(Type A1/2) = <10 hours

(Type A2) = < 36 hours

|

|

|

(Sealant Application) Cure time for PR 1440 (Type A1/2) & (Type A2) |

(Type A1/2) = 30 hours

(Type A2) = 72 hours |