![]()

![]()

![]()

Use LEFT and RIGHT arrow keys to navigate between flashcards;

Use UP and DOWN arrow keys to flip the card;

H to show hint;

A reads text to speech;

95 Cards in this Set

- Front

- Back

|

How does the addition of MANGANESE change the properties of steel?

|

Increases Toughness and Hardness

Used for components subject to wear and abrasion Surface hardens with wear/cold working while core retains it's toughness |

|

|

How does the addition of NICKEL change the properties of steel?

|

Increases Toughness and Corrosion Resistance

|

|

|

How does the addition of CHROMIUM change the properties of steel?

|

Increases Hardness and Corrosion Resistance

Chromium oxide forms on the surface, protecting from corrosion 11% chromium or more is classed as stainless steel |

|

|

How does the addition of COBALT change the properties of steel?

|

Reduces Hardness

Increases Tensile Strength at high temperatures |

|

|

How does the addition of MOLYBDENUM change the properties of steel?

|

Increases Toughness and Hardness

Increases Creep Resistance, especially at high temperatures Increases Corrosion Resistance in stainless steels |

|

|

How does the addition of TUNGSTEN change the properties of steel?

|

Increases Hardness, especially at high temperatures

|

|

|

How does the addition of VANADIUM change the properties of steel?

|

Increases Hardness

Increases Creep Resistance, especially at high temperatures Increases Corrosion Resistance |

|

|

Describe Borax

|

Fluxes in brazing are based on borax

Also known as Sodium Borate A mineral that converts water (H2O) into hydrogen (H) when heated, preventing oxidization Mixed with ammonium chloride for brazing steel |

|

|

Describe 'Deflection'

|

The ability to withstand a load without flexing out of shape permanently

|

|

|

Describe 'Toughness'

|

The ability to withstand the impact of a blow

|

|

|

Describe 'Hardness'

|

The ability to withstand wear, indentation or scratching

|

|

|

Describe 'Conductivity'

|

The ability to pass heat or electricity through it

|

|

|

Describe 'Dielectric Strength'

|

The ability to insulate from electricity

|

|

|

Describe 'Creep'

|

The tendency to deform under stress over time

|

|

|

Describe 'Metal Fatigue'

|

Caused by repeated loading to the materials elastic limits

|

|

|

Describe 'Tensile Strength'

|

The ability to withstand being pulled apart or stretching

|

|

|

Describe 'Elesticity'

|

The ability to return back to it's original shape

|

|

|

Describe 'Ductility'

|

The property that allows material to be drawn into wire or tube

|

|

|

Describe 'Malleability'

|

The ability to be formed or bent into shape without fracture or failure

|

|

|

Describe 'Brittleness'

|

The tendency to fracture without bending or changing shape

|

|

|

Describe 'Shear Strength'

|

The ability to withstand offset loads

|

|

|

Describe 'Compressive Strength'

|

The ability to withstand squashing forces

|

|

|

What are the main types of MMA electrode flux coatings?

|

Class (C) - Cellulosic

Class (B) - Basic Class (R) - Rutile Class (RR) - Heavy Rutile |

|

|

What are added to brazing filler materials and why?

|

Silver - Improves fluidity and strength

Silicon - Acts as a de-oxidizer Nickel - Improves strength Manganese - Improves strength |

|

|

What do fluxes contain that are suitable for brazing aluminium?

|

Alkaline chlorides

Fluorides |

|

|

What do fluxes contain that are suitable for brazing manganese?

|

Alkaline chlorides

Fluorides |

|

|

What do fluxes contain that are suitable for brazing silver?

|

Boric acid, potassium borates, fluorides

|

|

|

What do fluxes contain that are suitable for brazing high temperature ferrous metals?

|

Boric acid, alkaline borates

|

|

|

What do fluxes contain that are suitable for brazing iron and steel?

|

Borax, ammonium chloride

|

|

|

What is the difference between an element, a molecule and a compound?

|

Elements are the different types of atoms (copper, hydrogen etc.)

Molecules consist of atoms made from a single chemical element (oxygen O2 etc.) Compounds consist of atoms made from different elements (Water H2O etc.) |

|

|

What is the term for when a length of material expands due to it's temperature being raise by 1º

|

Coefficient of linear expansion

|

|

|

What residue is left after brazing or hard soldering with borax?

|

A hard scale of copper borate

|

|

|

Describe Dead Mild Steel

|

Contains 0.05% - 0.15% carbon

Very ductile |

|

|

Describe Mild Steel

|

Contains 0.15 - 0.3% carbon

General purpose steel |

|

|

Describe Medium Steel

|

Contains 0.3% - 0.8% carbon

Brittle but capable of being hardened through heat treatment Cannot be cold formed |

|

|

Describe High Carbon Steel

|

Contains 0.8% - 1.4% carbon

Very brittle but very hard wearing when heat treated Also called tool steel |

|

|

Describe Wrought Iron

|

0.01% - 0.03% Carbon

More workable than cast iron Easily Welded Good corrosion resistance No longer normally produced - replaced by steel |

|

|

Describe Cast Iron

|

Contains 2% - 4% carbon

Dampens vibration Easily fractured High compressive strength but low tensile strength |

|

|

Describe Alloy Steel

|

Carbon steels that contain additional elements

Example: For bicycle frames alloy contains 10% chromium and 4% molybdenum, increasing tensile strength and stiffness |

|

|

What is at the centre of an atom and what does it consist of?

|

Nucleus, which consists of protons and neutrons

|

|

|

What surrounds a nucleus?

|

Electrons

|

|

|

Describe annealing of aluminium

|

Annealing is a softening process

The aluminium is heated to 550ºc then quenched Aluminium with less than 6% copper will remain malleable unless work hardened Aluminium with more than 6% copper will harden after 2 hrs, longer if refrigerated at -20ºc the annealed aluminium can be left to 'natural age hardening' or artificially hardened by heating to 130ºc - 200ºc |

|

|

What simple methods can indicate correct temperature for annealing aluminium?

|

soap or wood (e.g. matchstick) draws a black line on the surface, showing the material is ready for quenching

Temperature indicating crayons |

|

|

Describe strain hardening of aluminium

|

The material is cold rolled. The metals grain is elongated, reducing malleability and increasing tensile strength.

A letter 'H' and figures indicate hoe much strain hardening from soft, quarter hard, half hard, three quarter hard to hard Also called work hardening or cold working |

|

|

Describe 1000 series Aluminium

|

Pure aluminium

Soft Highly workable Good conductivity Good corrosion resistance Cannot be heat treated |

|

|

Describe 2000 series Aluminium

|

Contains copper

Used for machine parts Used as a base for more complex alloys Can be heat treated Good strength Lower corrosion resistance than other aluminium alloys |

|

|

Describe 3000 series Aluminium

|

Contains manganese

Used for pot, pans and heat exchange equipment

weldable Good ductility |

|

|

Describe 4000 series Aluminium

|

Contains silicon

High castability High strength Good corrosion resistance |

|

|

Describe 5000 series Aluminium

|

Contains magnesium

Relatively soft but quickly work hardened High tensile strength High corrosion resistance Weldable Can be heat treated Used in automobile and ship building |

|

|

Describe 6000 series Aluminium

|

Contains magnesium and silicon

High strength Corrosion resistant Can be work hardened Easily welded Suitable for anodising |

|

|

Describe 7000 series Aluminium

|

Contains zinc

Brittle High strength High rigidity Weldable Can be heat treated |

|

|

Describe silver solder

|

Tin / zinc / silver alloy

Good fluidity and strength Melting point 620ºc - 855ºc Often supplied in flat strips referred to as 'spelter' |

|

|

How does the addition of phosphorous affect copper brazing rods

|

The rod becomes self-fluxing

Essential for hard soldering of refrigeration pipework, where the presence of flux would lead to contamination and corrosion |

|

|

What is the temperature range for borax or fluoroborate fluxes?

|

Above 750ºc

|

|

|

What is the temperature range for fluoride fluxes?

|

Below 750ºc

|

|

|

What is the temperature range for alkali halide fluxes?

|

Below 580ºc

|

|

|

Shielding gas is usually made up from what gases?

|

Argon

Carbon Dioxide - CO2 Helium Oxygen |

|

|

Describe Cartridge Brass

|

70% Copper, 30% Zinc

Can be formed and drawn |

|

|

Describe Admiralty Brass

|

70% Copper, 29% Zinc, 1% Tin

Can be formed and drawn Has improved salt water resistance |

|

|

Describe Free Cutting Brass

|

58% Copper, 39% Zinc, 3% Lead

Not suitable for cold working Machinable Used for thread cutting |

|

|

Describe Bronze

|

Copper with 2%, 10% Tin

Suitable for casting |

|

|

Describe Gun Metal

|

88% Copper, 10% Tin, 2% Zinc

Bronze alloy Also called free cutting bronze Good for machining |

|

|

Describe Phosphor Bronze

|

89% Copper, 10% Tin, 0.25% Phosphorous

Improved fluidity when cast Used for machine bearings and marine fittings |

|

|

Describe Martensitic Stainless Steel

|

Contains 86% Iron, 12-18% Chromium, up to 1.2% Carbon, 0.5% Nickel

Can be hardened Unsuitable for welding Used for chef's knives, hard wearing shafts and spindles |

|

|

Describe Ferritic Stainless Steel

|

Contains 76% Iron, 12-30% Chromium, 0.1% Carbon, 1% Nickel

Tough and ductile Cannot be heat treated Unsuitable for welding Good corrosion resistance at high temperatures Used for furnace parts |

|

|

Describe Austenitic Stainless Steel

|

Contains around 86% Iron, 18% Chromium, 8% Nickel, up to 0.15% Carbon

Comes in a range of alloys with different properties Most commonly used Malleable Non magnetic Weldable |

|

|

Describe Duplex Stainless Steel

|

Contains around 61% Iron, 21% Chromium, 9% Nickel, 2% Magnesium, 3.5% Molybdenum

High Strength High Corrosion Resistance Called Duplex because structure consists of 50% ferrite and 50% austenite |

|

|

What is the melting point of soft solder?

|

180ºc - 250ºc

Depending on the ratio of tin to lead |

|

|

What is an elastomer?

|

An elastic polymer, such as rubber

|

|

|

Describe natural rubber

|

Highly elastic

Excellent vibration absorption Good creep resistance ideal for tyres |

|

|

Describe Ethylene-propylene

|

Synthetic rubber

Known as EPM Chemically inert Good electrical insulation Resistant to cracking from age Ideal for insulating power leads |

|

|

How much carbon does steel need to contain for it to be heat treatable?

|

0.3% or more

|

|

|

How does heat treatment change the crystalline structure of metal?

|

Structure changes from body centre cubic (ferrite) to face centre cubic (austenite)

|

|

|

What are the three main groups of adhesives?

|

Solvent based - air drying, natural and synthetic

Thermoplastic - temperature setting, liquifies on warming, solidifies when cooled Chemical setting - relies on chemical reaction for curing, very strong, used for structural applications |

|

|

What was the first synthetic resin adhesive developed?

|

Phenol formaldehyde

|

|

|

Fluxes suitable for soldering carbon steel, brass, copper or tin contain what?

|

Zinc chloride

|

|

|

Fluxes suitable for tinning the soldering bit contain what?

|

Ammonium chloride (sal ammoniac)

|

|

|

Fluxes suitable for soldering zinc or galvanised steel contain what?

|

Hydrochloric acid

|

|

|

Fluxes suitable for soldering copper plated stainless steel contain what?

|

Phosphoric acid

|

|

|

What are the corrosive fluxes used in soldering?

|

Zinc chloride - used for carbon steel, brass, copper and tin plate

Ammonium chloride - used for cleaning the bit before tinning Hydrochloric acid - used for zinc an galvanised steel Phosphoric acid - used for copper plated stainless steel |

|

|

What are the non-crrosive fluxes used in soldering?

|

Natural resin - used for electrical components

Tallow - used for lead sheet and pipes |

|

|

What materials are spanners made from?

|

High carbon steel

Alloy steel containing chromium and vanadium Beryllium bronze (non-sparking) |

|

|

What qualities make a good filler alloy for brazing?

|

Achieve good bonding

Capable of good capillary action Melts at the right temperature Good resistance to corrosion Sufficient strength for the joint Compatible with the parent material |

|

|

What does LPG stand for?

|

Liquid petroleum gas

Also called propane or butane, which make up LPG in varying ratios |

|

|

Describe thermoplastics

|

Also known as thermo-softening plastic

Softens when heated then re-hardens upon cooling |

|

|

Describe thermosetting plastic

|

Irreversibly cures through heating or chemical reaction (e.g. two part epoxy).

Once hardened they cannot return to a liquid or softened state |

|

|

All carbon steels contain what additional elements?

|

Silicon

Sulphur Manganese Phosphorous |

|

|

What is Cementite?

|

A compound of iron and carbon

Also called Iron Carbide |

|

|

What is Pearlite?

|

Alternate layers of ferrite and cementite

|

|

|

How much Chromium does steel have to be classed as Stainless Steel?

|

Approximately 10-12% or more

|

|

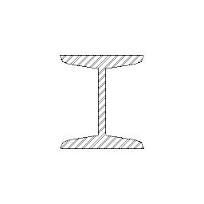

What is this?

|

Universal Beam

|

|

What is this?

|

Universal Column

|

|

What is this?

|

Parallel Flange Channel

|

|

What is this?

|

Rolled Steel Joist

|

|

|

What is the formula for calculating drill speeds?

|

RPM = 30,000 / 3 x drill diameter

|